You must be logged in to rate content!

8 minute read

A/C delete

Compliments of Heyfred @ http://ls1tech.com

1-26-2009

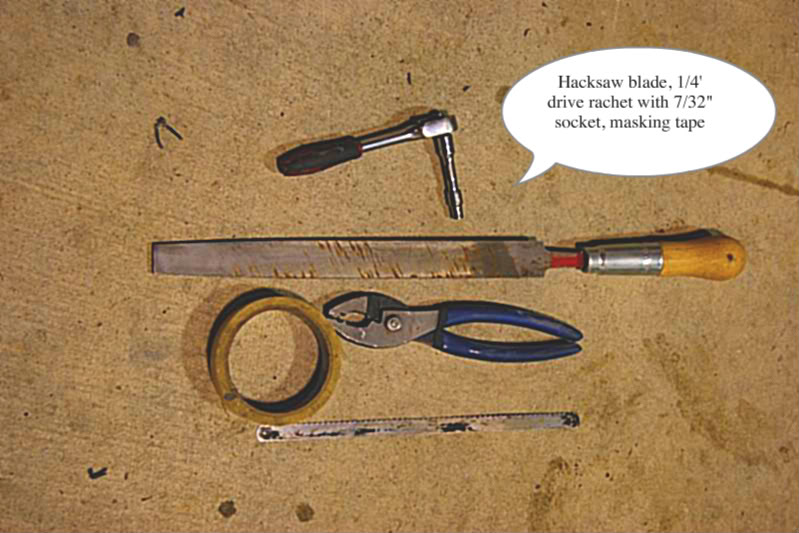

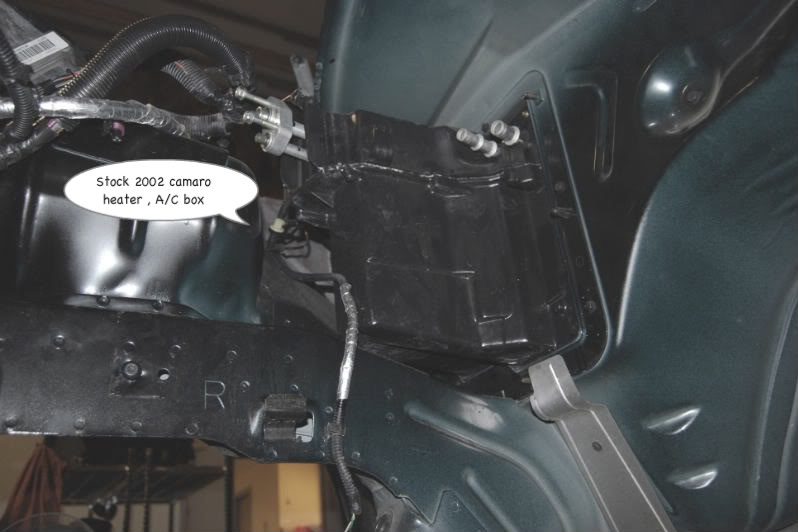

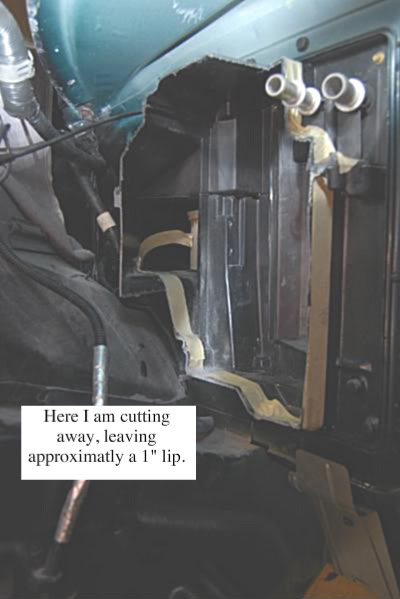

Decided to do the a/c delete and made a step by step of how I did it.

I am starting with the engine out of the car.

It has been a long day, so I will go back at in the morning.

For Sale

http://www.ls1tech.com/forums/northw...l#post10940932

http://www.ls1tech.com/forums/northw...02-camaro.html

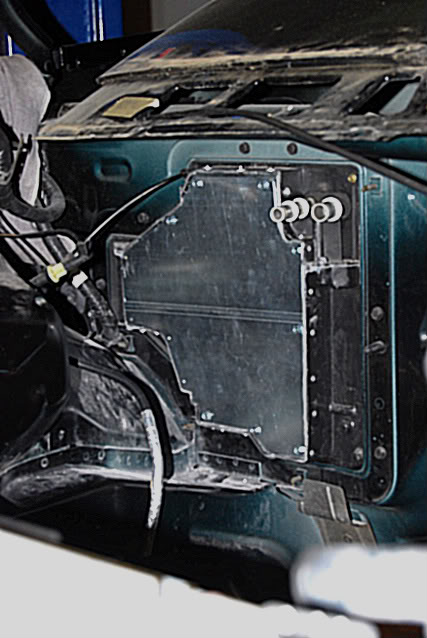

Cover is done.

I have to get an angle drill so can finish installing the screws and some sealer to go around the outer edge of the cover. Also to put the rivets to keep them from leaking.

1-27-2009

I have not weighed the A/C, but from what I have read on the site, it is a 51lb weight reduction.

If I can locate a scale, I will weigh the parts.

This might help:

http://www.ls1tech.com/forums/drag-r...tion-list.html

21.5!AC compressor

8.5.!AC condenser

1-28-2009

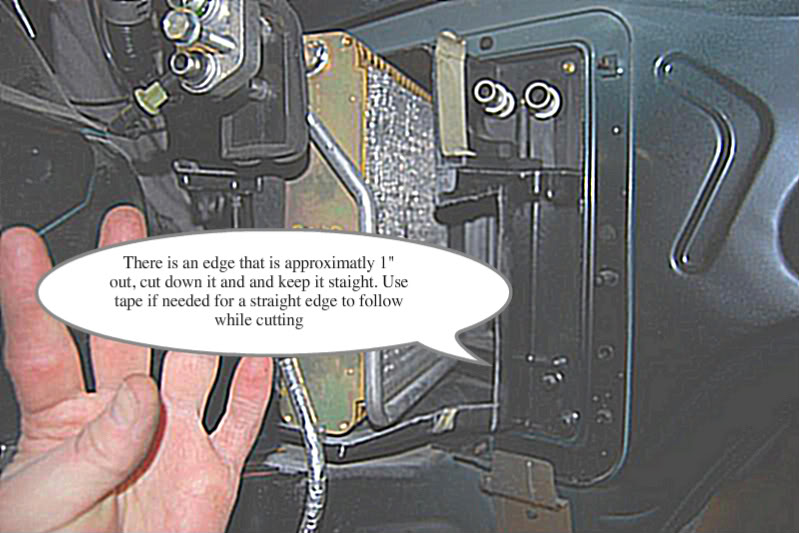

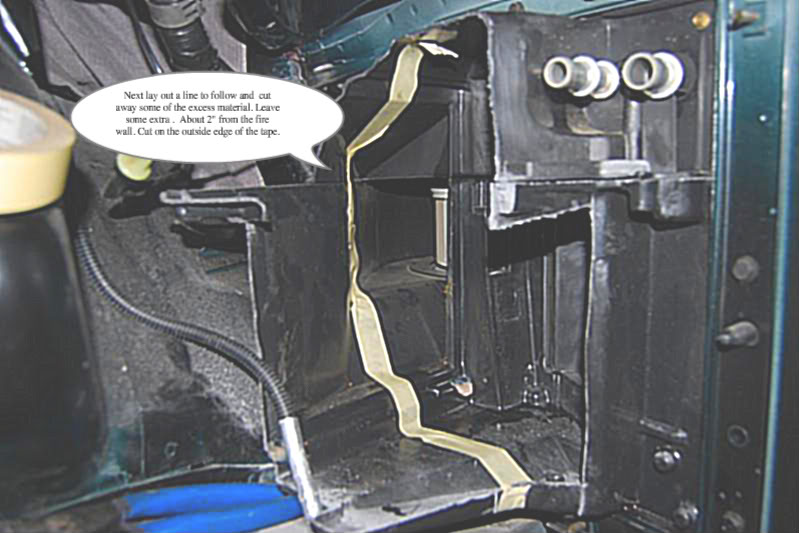

I made my forming strips 1" wide because the masking tape made it fast and simple to lay out for cutting out the sheetmetal. Put your bend line on the forming stirps at a 1/2". Make up several long strips and cut them to length as needed. One thing that helped was: If you are drilling from the inside of the box out for the rivet hole, predrill the holes in the forming strip so you can use them for a jig for drilling the rivet hole thu the plastic. Note: When installing a rivet from the inside of the box going out thru the pastic, be sure to put a washer on the rivet before setting it or the plastic may crack.

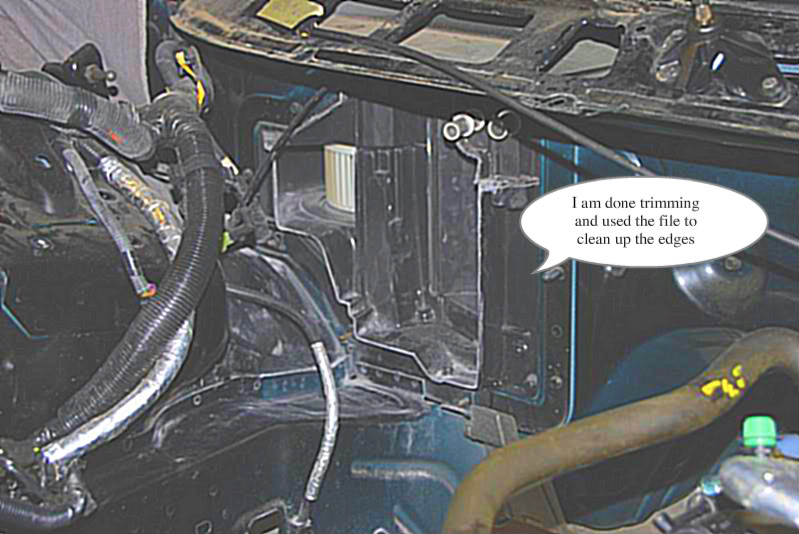

Next; go to your hammer and vice press brake and perform your bends as needed. Using a plastic hammer, bend the forming strip as needed. I used 22ga galv sheet metal so you don't have to hit the material with alot of impact to make it move. When positioning the forming strips in the vise for bending, don't hide the bend line in the vise jaw.

The material grows as it bent. Practice forming several pieces, so you know where to locate the line in reference to the vice jaws to make them come out uniform. Form the material to 90 degrees or as needed. Be gentle

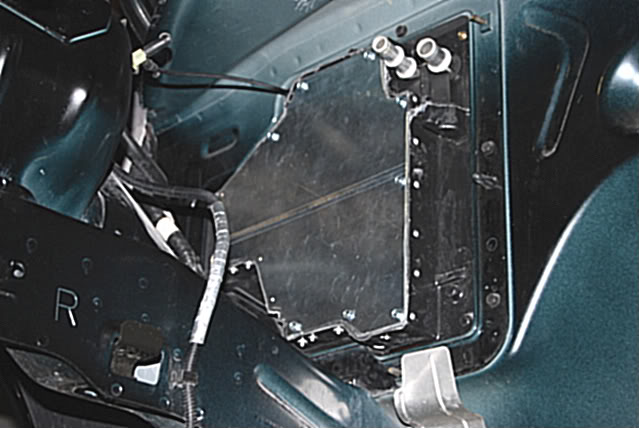

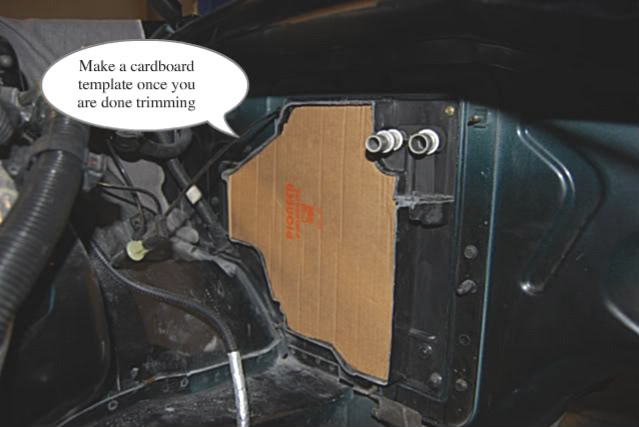

This is what it looks like once you have fitted forming strips. Be patient.

Note:Pop riveted exta material in the corners for strength and to give more material in those areas to locate for the screws that will hold on the cover plate I did this at all corners.This also give 2 metal thicknesses for the cover plate scews to go thru.

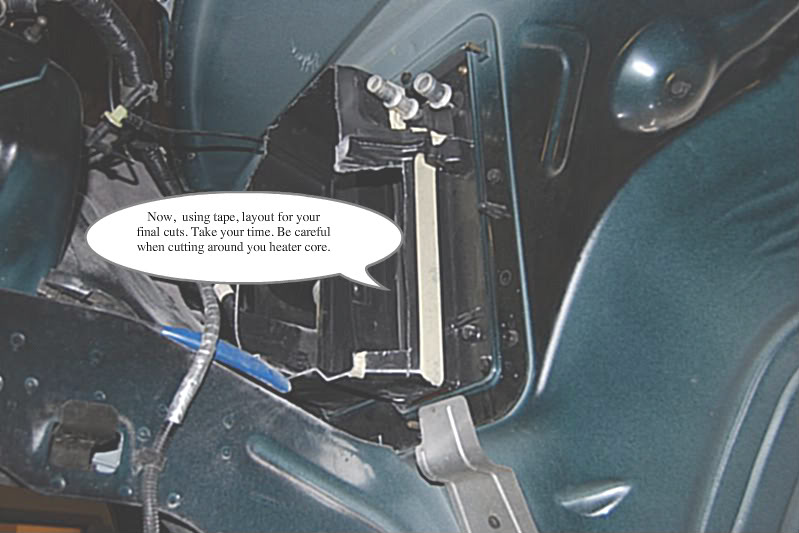

If you have not already, cut out your cover plate. On your cover plate, if you have a good side you want to show, make sure you cut it out in the orientation so it faces out when bolted into place. Put masking tape around the edge and trace your patern and cut out

Measure in 1/4" so you have a reference for lining up and locating your cover plate holes.

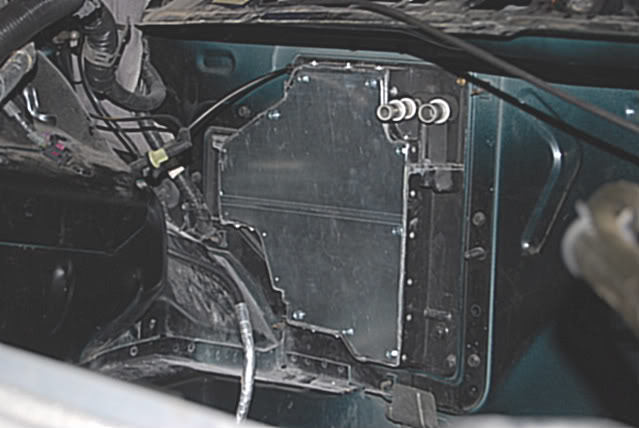

Position the coverplate and mark with a maker/ pencil where you want your holes to be. Then take it to the bench, center punch the points and drill with the 1/8" drill bit.

Using the cover plate as a templte, position it back onto the car, hold it in place, using the 1/8" bit, drill 2 or 3 holes thru the forming stips.

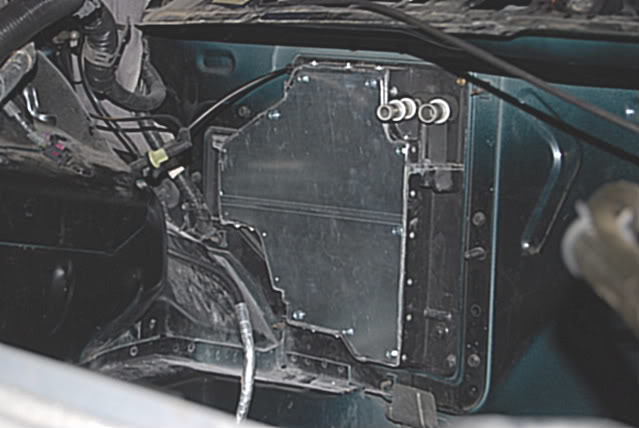

Remove the cover plate and drill the 2 or 3 holes you just used as a template in the cover plate to 3/16'. Reinstall the cover plate using the self tapping srews thru the holes you drilled to 3/16", attach the cover to the car. Put the 1/8" bit back in the drill and drill the rest of the holes into the forming strips.

Remove the cover plate and drill the rest of the holes too 3/16". Reinstall the cover plate and insert the rest of the self tapping screws.

Remove the cover plate and seam seal.

Paint the cover plate and let dry.

Once cover plate is dry, put a bead of seam sealer on the back of the cover plate and position on the car and secure with the self tapping screws. Next, put a bead of seam sealer around the outer edge. The cover should be free of leaks.

I purchased an angle drill part way thru this project and made drilling alot easier because of the tight area.

We are done.