You must be logged in to rate content!

4 minute(s) of a 27 minute read

11-6-2011

My ongoing Honda project

Compliments of Mafdark @ vwvortex.com

11-6-2011

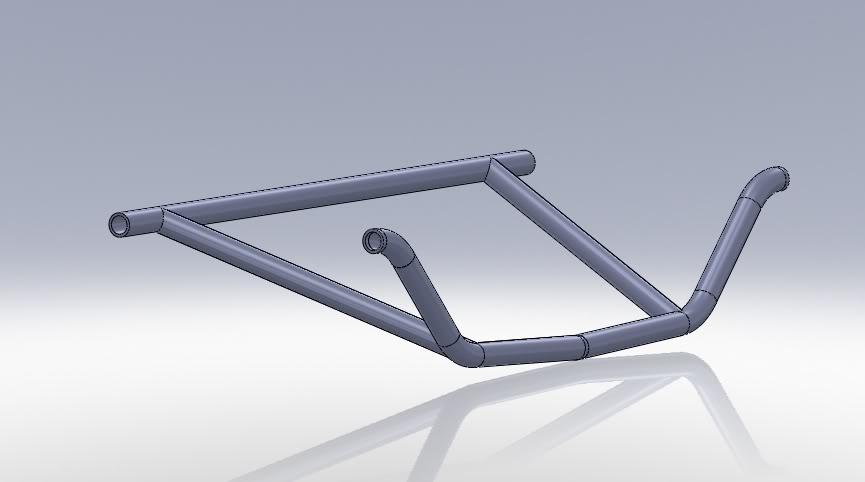

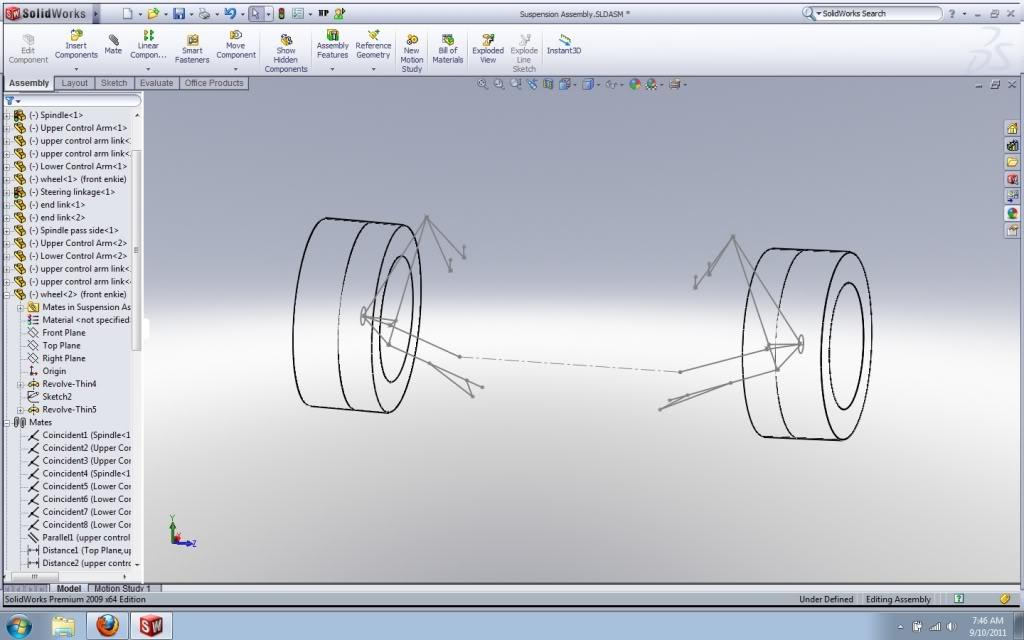

Just started frequenting this forum a little bit more and I thought I would share a handful of pictures of my project car, I think these will be pretty self explanatory:

It's been evolving since I bought it in '03/'04. The current setup that I'm working on and posted pictures of here was work that began during the spring of 2010

Correct, although its a K24 bottom end so its a slightly taller K20.

This is actually my mockup motor. Completely empty casings so I can maneuver it for mockup.

I'm a little modest, always keep some things up my sleeve, and love technical discussion. I'd rather you ask what you want to know rather than me making a list. ![]()

-by no means take this as me not wanting to talk about it. I'm always happy to get into details with people.

I wanted it to be the fastest track car possible while meeting these requirements.

Must be capable of:

-Grocery runs

-road trips

-sunday drives with the wife.

now to cheat a little bit, I do have plans for a "road" setup and a "track" setup so I built in a few features/components that can easily be switched out trackside with basic hand tools.

Keep posting, great build!

Posted by Diggymart on 11/14/18 @ 1:41:04 PM