You must be logged in to rate content!

6 minute read

Vented Aluminum Hood

Compliments of Gearhead @ https://www.s2ki.com

9-23-2005

After posting some pictures, I received some requests for a DIY thread.

Rationale for this mod:

I wanted a vented hood for three reasons. 1. To let heat (from header, engine, & radiator) escape from engine bay 2. To get cooler air into intake 3. To use the low pressure area above the hood to help extract air from under the front of the car thereby increasing velocity under the splitter and floor of the nose which should increase downforce.

Why not buy a carbon fiber vented hood? The affordable knock-off carbon hoods are heavier and less stiff than the stock aluminum hood. I believe the stock hood weighs 14 pounds. The high quality "authentic" hoods (cwest, mugen...) cost a bundle and still need to be painted unless you are going for the carbon look. Some if not all composite hoods require hood pins for high speed use. Oh yeah, and I'm cheap. I planned on venting both sides but ran out of time and decided I like the look of just one side. Still debating.

Here's my solution:

How to build your own.

Please use appropriate safety equipment and don't screw up.

Yes, you are about to cut holes in a perfectly good hood so be prepared.

Remove the hood and the hood liner and support it upside down on some padded saw horses.

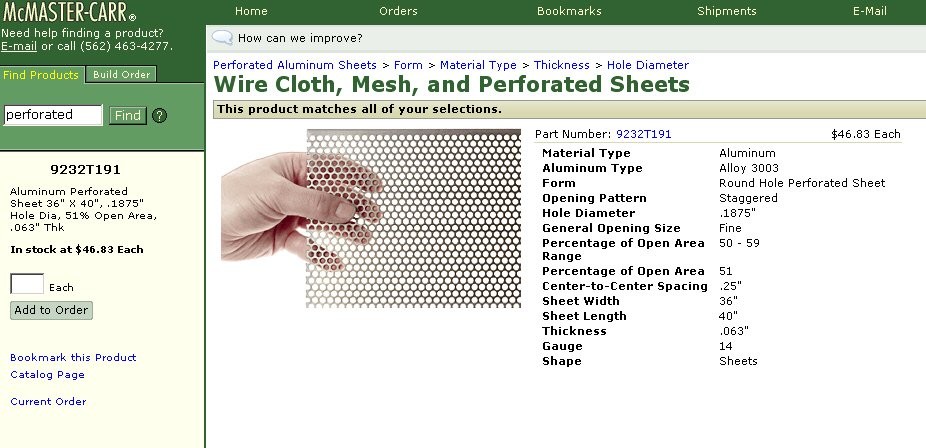

Make templates by laying paper over each support hole and tracing the edge (use the pencil rubbing technique). Use the templates to cut out some perforated aluminum (clean and paint the both sides of the aluminum). http://www.mcmaster.com/

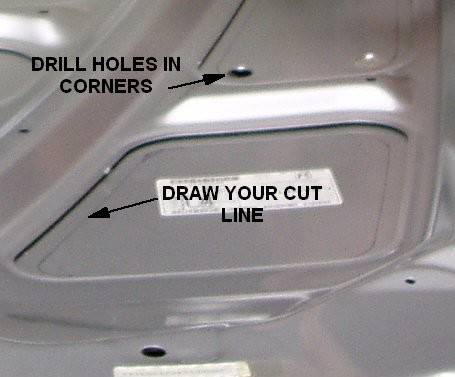

Use a 3/8" spacer against the hood support edges to draw the hole shape. I left a 3/8" lip for mounting purposes.

Using a UniBit, drill a hole in each corner. UniBit

Using an air saw, cut out the shape from the under side - leave a small gap to finish off with sanding. Air Saw

Use a sanding drum on a die grinder to smooth to shape. I tried using a sandpaper wheel on an angle grinder but it gets too hot and the paints starts to peel back.

Once the shape is close, flip the hood over and apply masking tape on the top side all around the new openings.

Use wet dry sandpaper to smooth the cut and feather the paint. The masking tape is there so if you slip with the sandpaper, you won't scratch up your hood.

Lay 3M double stick tape used for moldings/body work on your 3/8" lip and trim with a razor to fit just inside the cut out (find it at automotive body shops).

Use a fine paint brush and carefully paint the exposed edge with factory touch up paint.

Install perforated aluminum and your done. I used some small sheet metal clips to hold the perforated aluminum in place just in case the double stick tape failed due to engine heat but I ran a full track day without them and everything was fine.

9-27-2005

Thanks for the compliments. My car is a daily driver and I live in Seattle so it does see a fair amount of rain which doesn't seem to be an issue. As others with vented hoods have mentioned, you can see the heat waves pouring out of the hood when stopped. At speed, initial testing has shown about a 20 degree drop in intake temps which is fairly significant considering I have already performed several other modifications that have reduced intake temps measured via OBD-II from the intake air temp sensor.

I believe that there is enough of a pressure differential between the top surface of the hood and the engine bay/under car to cause flow out of the hood without the need for additional vent geometry such as an upswept leading edge etc. I will attach some streamers to the hood and vents and verify this on the freeway.

One could also make a rain channel very easily. I may work on this in the winter for the heck of it.

3-22-2006

Nice work on the carbon hood. I got a little more practice recently on a Silverstone. A lot easier the second time and the results were perfect. BTW, I highly recommend having the perforated inserts powdercoated - very durable. For this car, we used a different vent pattern at the owners request. Click on pics for high res.

3-27-2006

The hooks I used are U-Style clip on nuts, you could use any "clip" designed for sheet metal.