You must be logged in to rate content!

13 minute read

TJ Mini Boat side rockers

Compliments of cgmrdc @ jeepforum.com

11-5-2009

Figured id do a write up of this for anyone who wants to build a set...

I REALLY like the look of the Poison Spyder richochet rockers and the functionality of Genrights mini boatsides and since i cant afford either and love fabing my own stuff I thought id combine the two and make my own!

The rockers are made of 3/16 steel and the tubes are 1.25, .120 wall HREW

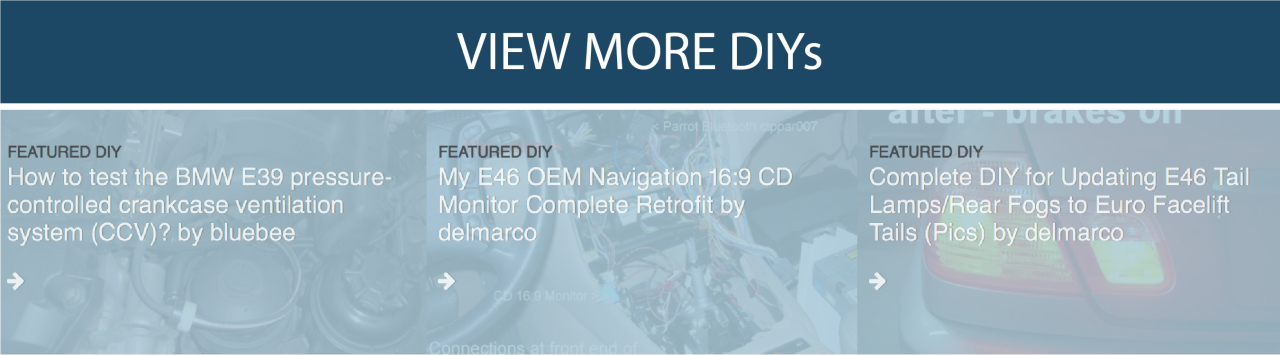

Started by cutting out the rockers

58 x 14.25

then cut where the bends go... leaving 6 1" gaps to hold it together

1st bend is 4.75

2nd bend is 3.5 from that

Next set up on a heavy table and clamp it down as much as possible. I used 2 large pipe wrenches to bend them

Top bend is 120* and the second bend is 150*

next you need to bend the pich seam under to gain the extra clearance of the boat side... this is the hard part if youre like me and had perfect rockers

you need to cut where the fender meets the tub so it can fold there... its just 1 inch up at a 45 deg angle... ill take a pic

once that is done you need to cut out the bottom to clear the body mounts... Ill get dems tom too

mount it up to see if the rockers needs to be messaged anymore...

repeat for the other side

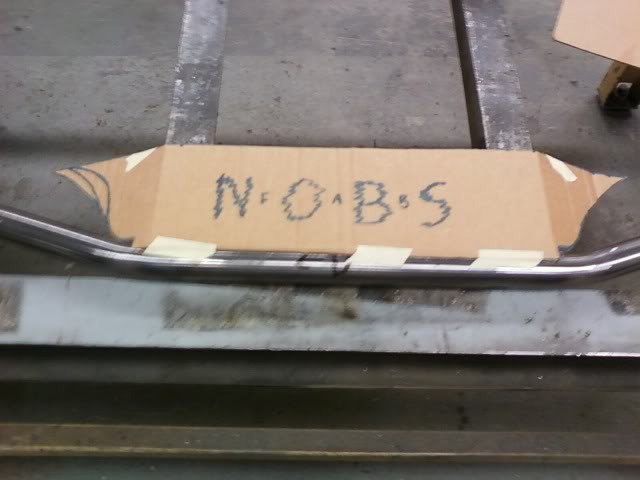

Here is the shape of the tubes... ill get the autocad sketch and ad dems or you can bend whatever tube shape you want... or none...

Next is welding it together... alternating rockers and ends of the rockers with time too cool... i doubt theyll warp but better safe then sorry

after everything is welded up and you test to make sure they didnt warp or pull out grind the welds smooth. with the welder turned up you should be getting 100%+ penetration

Thats where im at as of today, ill keep updating and get the dems as I progress!

11-12-2009

$120 4'x8' 3/16 steel plate... which will also make my front bumber and steering box skid

$20 20' 1-1/4 HREW

$25 stainless steel nuts and bolts

i used half the stick of tubing and between half and a third of the sheet... so def a lot less the $499...

11-16-2009

got the sliders on for a test run to flat nasty this weekend. The clearance difference between these and my old tube steps is unreal! i actually had to purposefully drive over a rock to get them to hit just so i could see how they held up, and that was the only time i touched them all weekend... but now the lowest point is the body mounts so im gonna fab up some skids for those too

backing plates on the sides are 2x1/4 stainless strips, floor is 2x1/4 mild...

10 stainless counter sunk bolts per side for a nice smooth surface.

now that wheelin season is over....... im gonna pull these off, stripem back down, weld the tubes on, clean up some of the grinder marks and ill paint it gunmetal to be the same color as the TJ

11-17-2009

there are 4 bolts underneath, ill snap some more pics when i get the mud off and pull them off to finish the tubes

11-22-2009

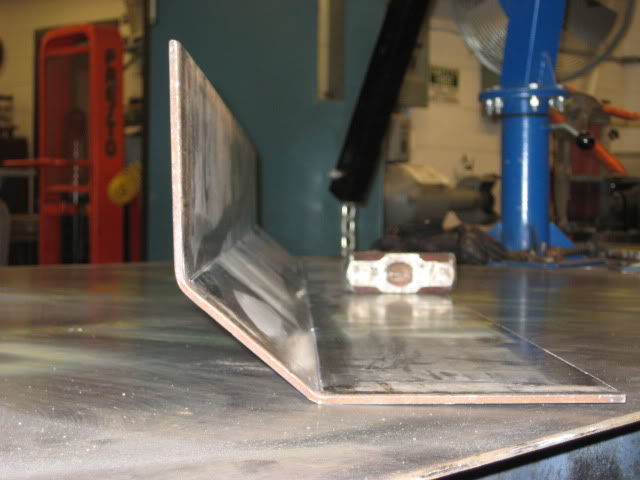

got the tubes welded together and the step plate roughed out of cardboard. the NOBS will be free hand plasma'd

11-30-2009

o crap... sorry... heres one pic that kinda shows it... and its a bad *** pic ill get a driveway shot tom

ill get a driveway shot tom

there are three bolts between the first and second body mount that go through the floor and are sadwiched between a peice of 2x1/4 strap and then one between the second and the third through the floor and plate with a peice of 3/4in channel as a spacer where the tub slopes up.

12-1-2009

nope

i was on thanksgiving break last week and had to leave all my tools at school. and i was busy working on hiline tube fenders for a friend.

I hope to have the fab done this week... then its sit around and wait for a warm enough day to paint. also ill get all the pics and measurement requests today when i take them off the jeep

finally got some more work done...

the step

still need to cut and weld the corner "gussets" and plasma the "NOBS" out of the step... and then do it all again to the other side lol

and i got your guys' requests... the bends...

and the underside mounts

fronts:

rear:

pretty simple... ill get flat head stainless fasteners eventually, i just wasnt sure of the length yet and they are kinda expensive.

did i miss anything?

these are a ton of work but im really happy with how they are turning out. and the responces so far are really helping to keep me motivated

yeah i do, but i have 33x13.50s on 15x10 soft 8s with 3.5" bs so my stance is really wide. if i flex out with my street tires (33x10.50 on 16x8 soft 8s with 4 in bs) i barely rub at all. but when wheelin its pretty manageble. the outer lugs of the tsl pull pretty hard on the flares but so far i havent broken or pulled them off.

this is at full bump with stock bump stops. if you dont want them to rub you can add some hockey pucks in there.

the hiline fenders are made with 1.25 .120 wall HREW... same mat as my steps... and when these are done ill be making a set for me

12-2-2009

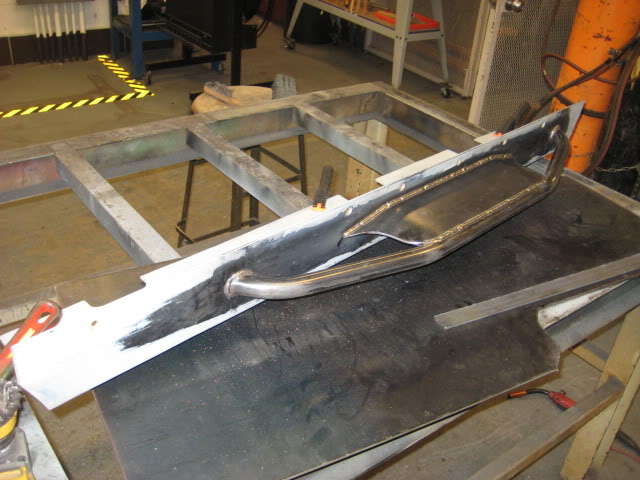

all fab is done on the drivers side!!!

and the now the pièce de résistance...

now its just wait till its warm enough to get these painted and done with!

yep, this pick shows the backing plate for the top row, then there is a similar one for the bottom row. it it 2x.25 stainless steel.

12-7-2009

fab is finally done on these sliders!!!

and the pair together!

12-8-2009

its actually 3/4". the sliders mount to the body between the 1st and 2nd body mount, then it slopes away after the second. which is why i used the spacer.

12-9-2009

before i added the the tubes i was able to lift from the cut out around the front body mount with out any deflection of the rocker or tub but now i had just planned on lifting off the tubes. we have put tubes of the same material on many sliders in the past, xj, tj, yj and even an fsj on 38s and to my knowledge no one has crushed a tube. they are burned in hot and so is the plate because i knew they would see a ton of leverage all the way out there so im not worried about them holding up to a lot more then a hilift jack. if I have a problem i can redo them with .25 wall i suppose...

thanks everyone for the kind words!

2-15-2010

its been a long time since ive done anything to these bc ive been building tube fenders and havent been wheelin so these have just been sitting around till my fenders were ready to paint too

just primer atm... but heres whats been part of the delay