You must be logged in to rate content!

3 minute(s) of a 464 minute read

3-10-2010

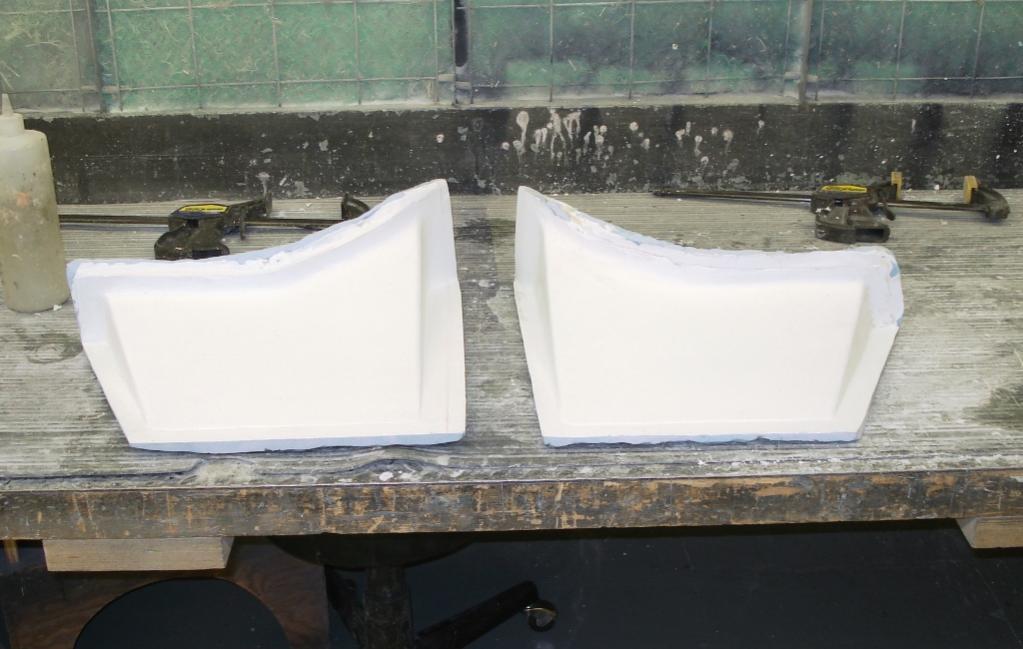

Front diffuser molds seperated, they turned out nice. Just need to do some clean up, sanding and polishing of the gel coat and the molds will be ready to make some parts. Will be getting flat stock in a few days to start working on the splitter laminates. Will be doing a thee piece laminate so the top and bottom surface will be smooth and once bonded together should be super stiff, even when made out of fiber glass.

4/18/10

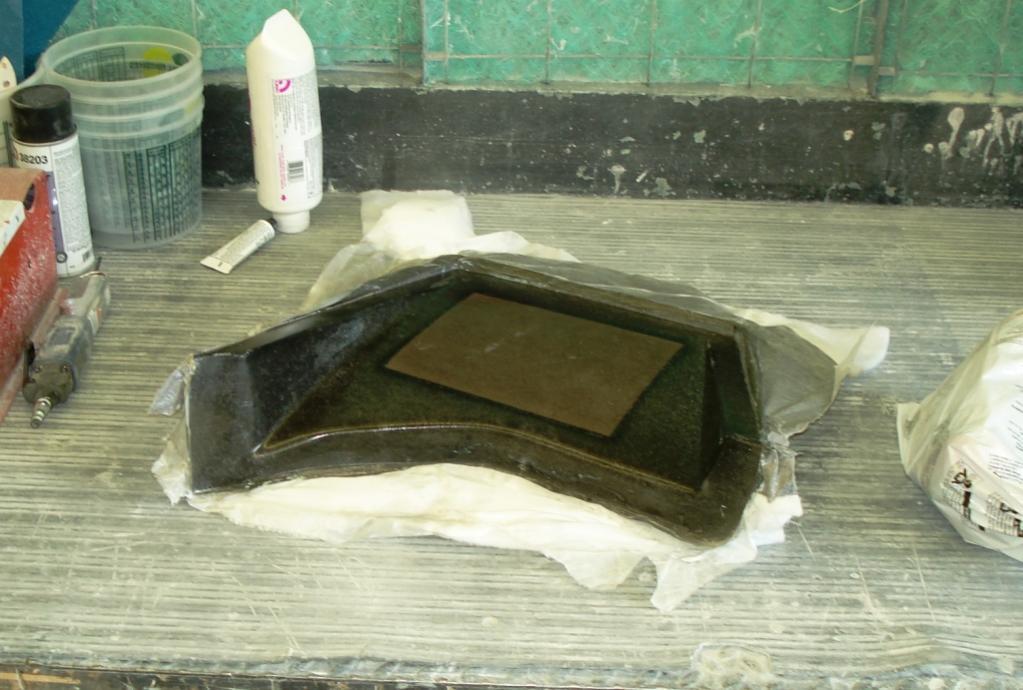

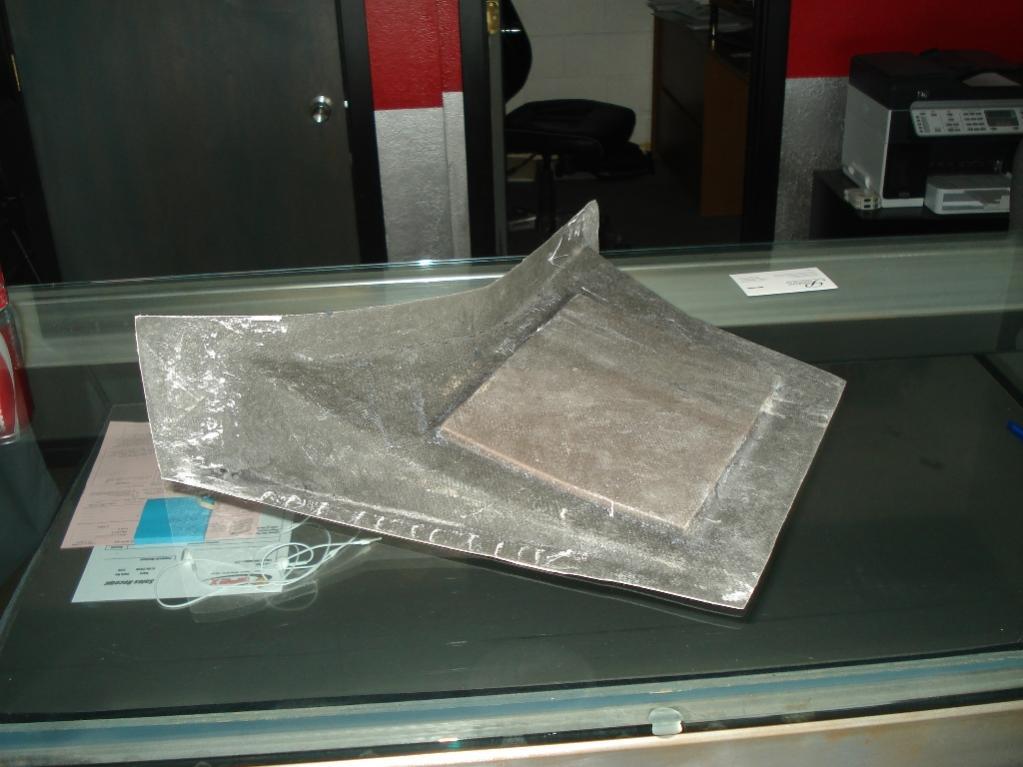

Prototype splitter/diffuser part made, turned out pretty good. The part turned out really light and really stiff.

Making some changes, ordered a different resin that not as viscous and also ordered some stretchable vacuum bagging material. Also got a killer deal on some 3K twill weave carbon fiber. The plan is to test the front splitter on the 8th of May at ORP PCA track day.

4/20/10

Alright! Got the new resin and stretchalon 800 vacuum bagging material today so I will be making the other prototype diffuser part tonight. And planning on making the splitter this weekend.

4/24/10

Alright! Second part turned out really good except for the tight corners. Looks like I will have to create a epoxy or gel coat layer to get a smooth surface. Used a lighter weight fiber glass as the first layers to get a better surface without the air bubbles like the first one, it worked, but still need to tweak the process.

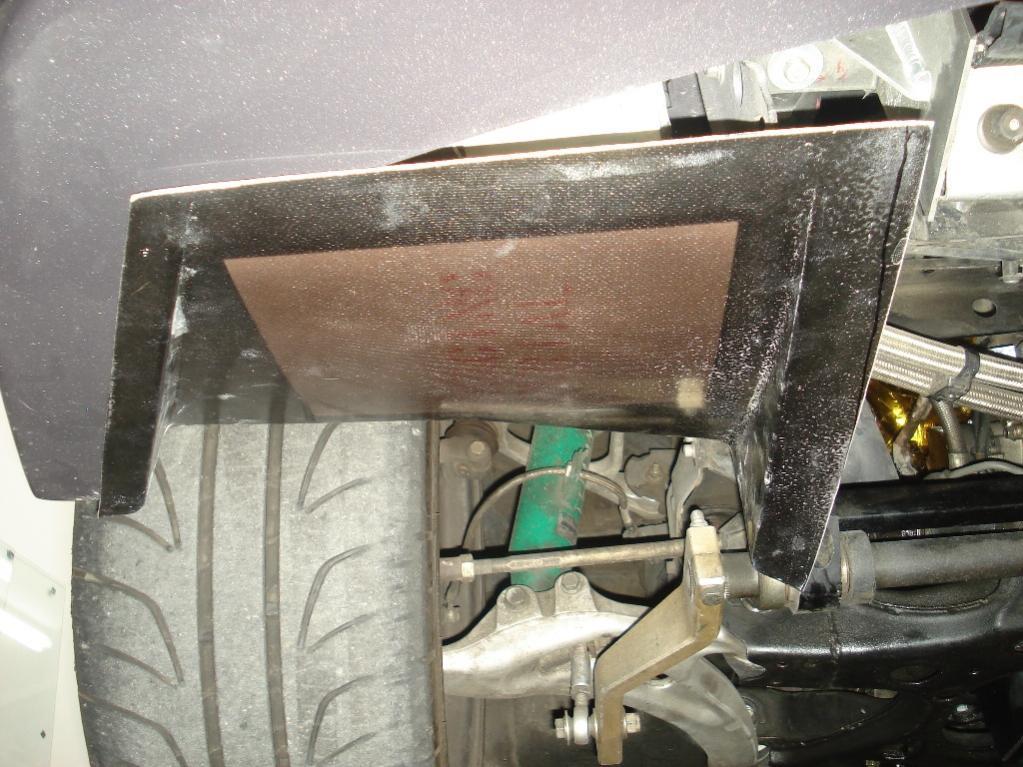

Anyways did a mock up of the diffuser pieces on the car, looks good. May have went to wide considering the sway bar is directly aft of the diffuser, but will do some flow studies to see how it interacts. Will be making fences for it to help keep attached airflow.

Will start on making the splitter piece Monday.

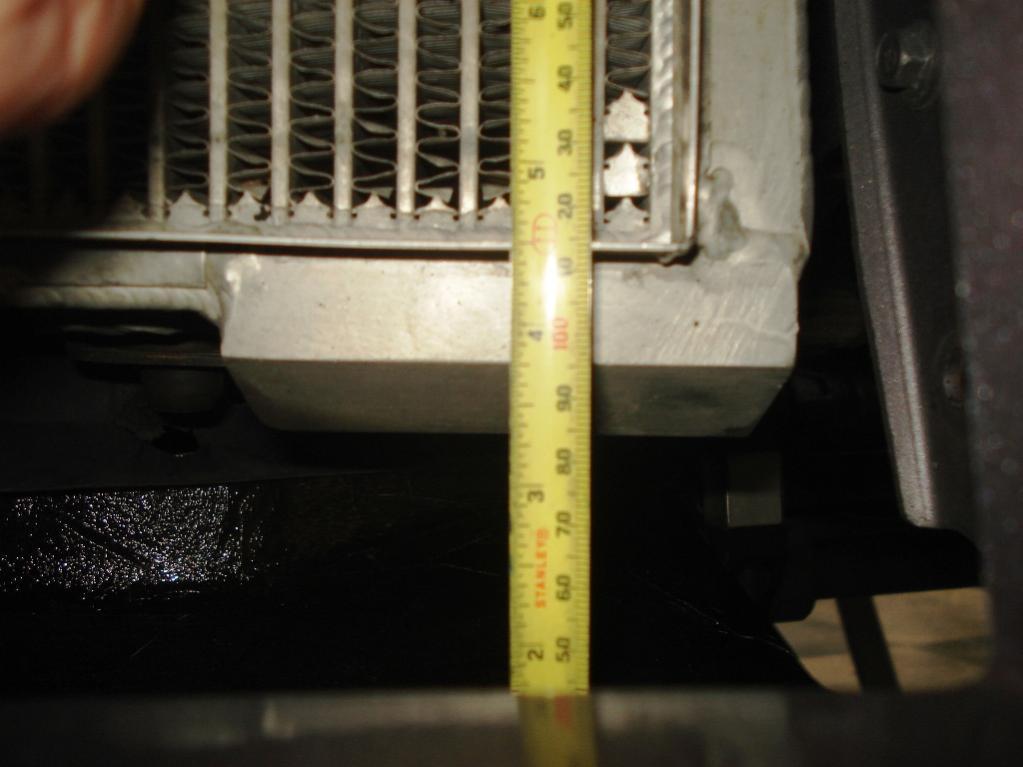

Getting the car prepped for the ORP track day on the 15th. Looks like I can drop the oil coolers, originally set them up high to clear the diffuser piece, but it looks like I went a little overkill. Will fix than down the road.

Nice build!

Posted by Diggymart on 12/10/19 @ 12:54:14 PM