You must be logged in to rate content!

8 minute(s) of a 203 minute read

1-7-2011

1973 Midget build

Compliments of ianjoub @ mgexp.com

1-7-2011

I have had a thought in my head for a while.

I want to get an Austin Healey Sprite or MG midget and stuff a hayabusa engine in it. The plan is a 25-30 psi turbo to make +/- 550 hp and a target weight of 1500 lbs.

I went to look at this beauty, the car portion of the project!

http://ocala.craigslist.org/pts/2089918303.html

This should be the ultimate super sleeper

I will use this thread as the build thread as things progress.

Step 1: get the car.

Step 2: get it running as is, go through the chassis, update the suspension, brakes, and generally make sure it is a good platform.

Step 3: Get a hayabusa, then fit the motor into the car.

Step 4: remove the motor, build it to the obscene hp specs and reinstall.

Step 5: Upgrade the driveline if necessary

Step 6: finish the cosmetics.

Wish me luck

I hope to have $0 in my chassis after I purchase the MG, then sell the existing motor and trans..

Well, here it is!

$800 and it started and drove onto the car dolly under its own power.

Needs a new rag top

It has some cancer on the hood and trunk lid, but you can buy new ones. The frame and rear section of the car are solid as is the floor.

Amazing how samll it is

Overall the interior is in great shape, for 38 years old.... Carpet is good, door panels are good, seats have no rips/tears.

I have a completion date of Jan. 2013 in my head. 2 years seems reasonable!

So, here is the engine bay. Yes, that is 30" from side to side!

The squarish metal 'box' there under the coil and red wires is the passenger footwell, where your feet are when riding in the car. The driver side is the same. That is 15" between them at this point!

I may have to move the busa motor forward in the car from where the stock motor is and relocate the radiator, oil cooler, and intercooler.

After sitting in it, I thought I might replace the gas tank with a fuel cell in the trunk so I could move the seats back 4 or 5 inches, but the wheel wells are right there as is the clearance for the rear axle.... I guess that idea is a no go.

Ok, did a survey today:

This is the exhaust and gas tank. The tank is weeping fuel. $200 for a new one. The exhaust is rusty, but still solid. It will do for now. When the busa motor goes in, it will all go in the trash. That should save 40-60 lbs right there!

Sprayed every bolt/nut I saw with PB Blaster several times during the day. That will continue every time it is on the lift.

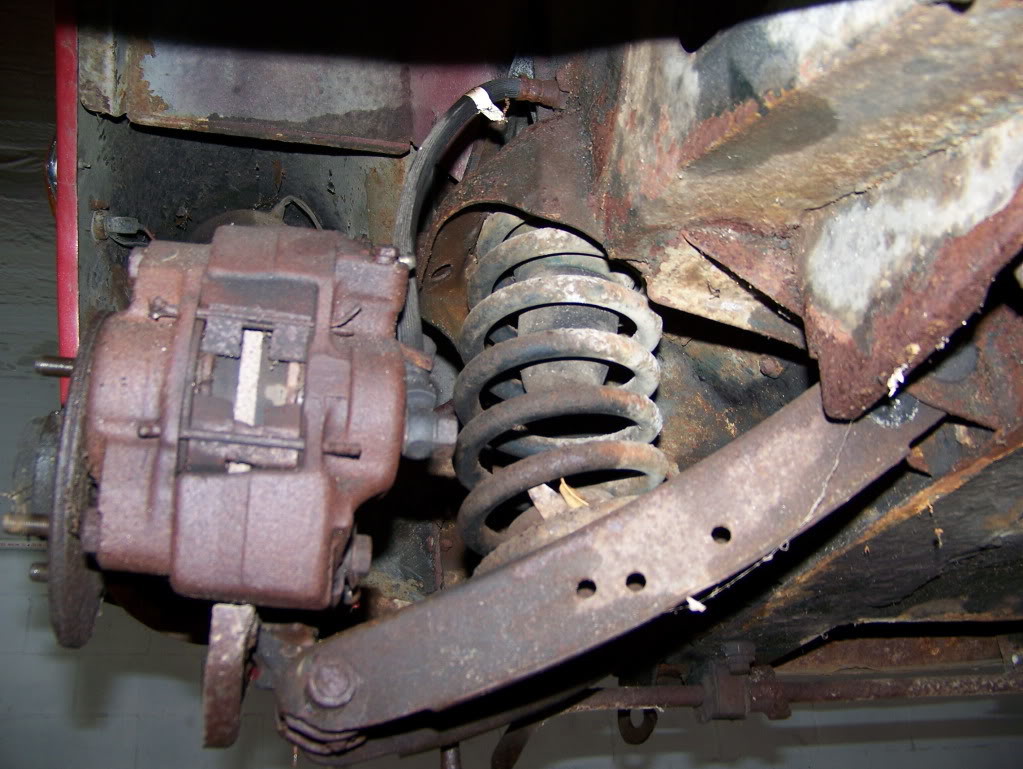

These cars are equipped with lever style shocks on all 4 corners. The manual I have has no disassembly instructions, so I will have to wing it changing the oil in them.

Flat bottom cars are cool! It really help the aerodynamics, makes it suck down to the road. You can see some rust on the passenger side floor. It is only surface rust, no cancer. Sandblasting and new undercoat will fix that.

Did the valve adjustment, oil, and filter change today.

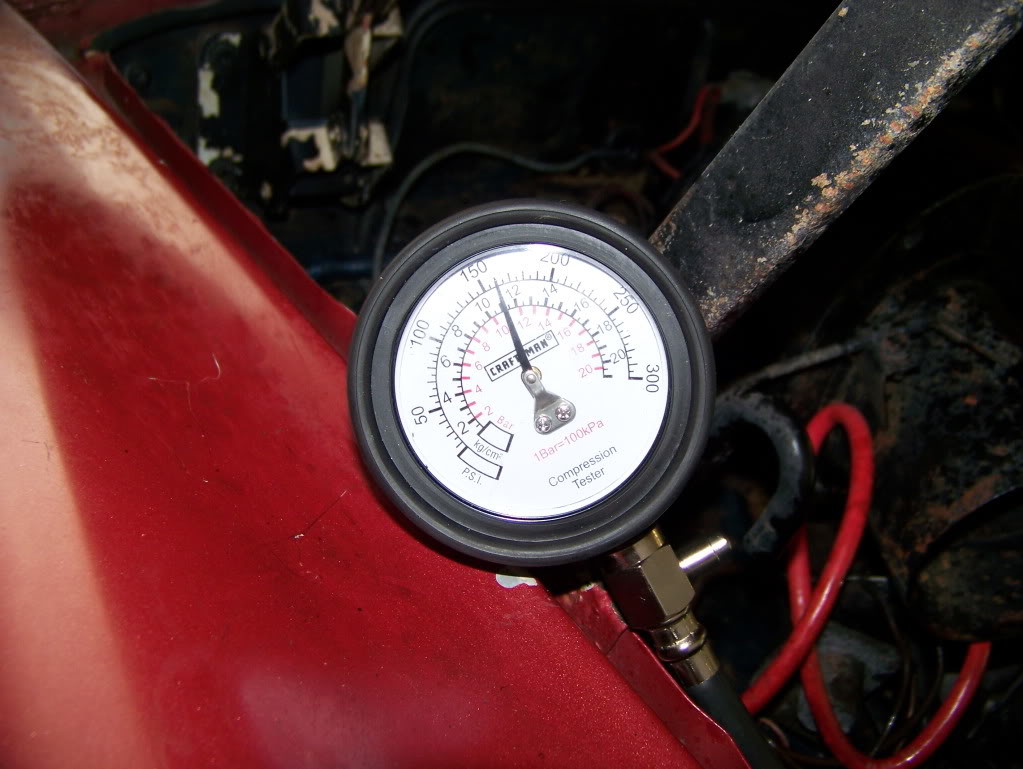

Put in new plugs and did a compression test on all 4 cylinders. All 4 were within 5 psi of each other

The inner wheel wells are in good shape. Very little rust. Once again, I will sandblast and undercoat them. The front side of the exterior has a few bubbles. I will grind that off and see if it needs some metal welded in or just some bondo.

At some point I will sandblast the entire diff housing and paint or powdercoat it. Probably when I install the limited slip diff internals!

It will get new/heavier coil springs, they will lower the front 1/4" as well.

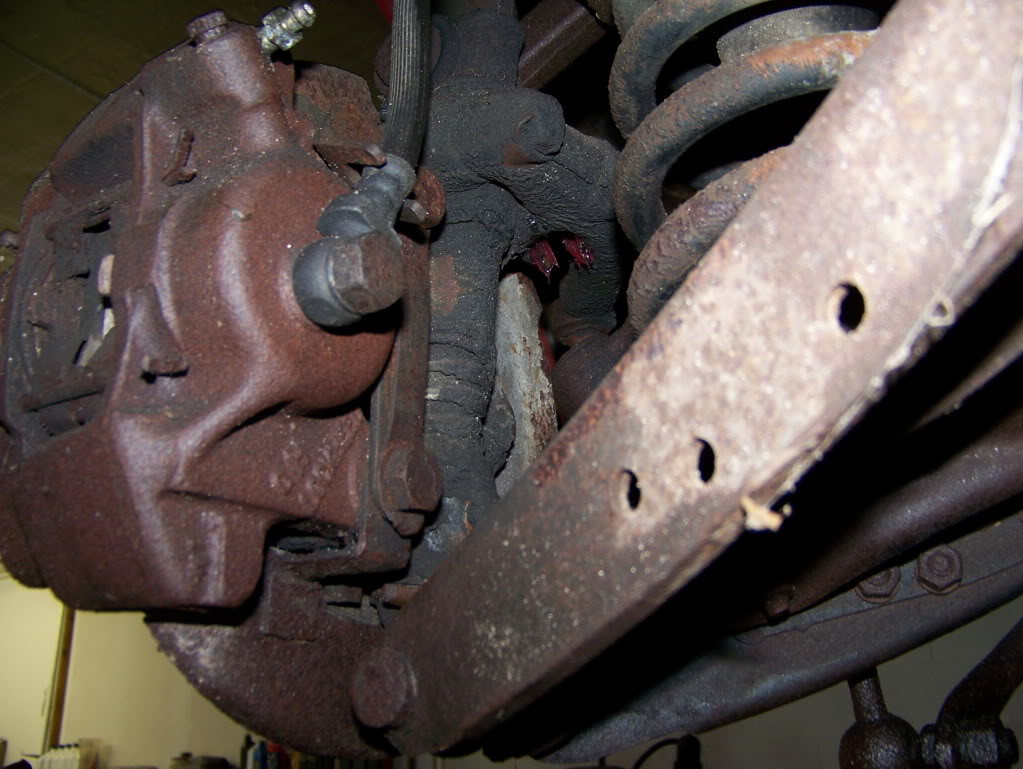

The entire front suspension will be removed. I will buy the hard neoprene bushings for the control arms, shock linkages, and kingpins to give it the sportscar quality ride. While apart, all the pieces will get sanblastd and powdercoated.

The 5/8" sway bar will be replaced with a 7/8" one with new neoprene bushings. That will help a bunch with suspension duties!

New inner and outer tie rod ends will be installed as well. While the suspension/steering stuff is off, I will sandblast and undercoat the inner wheel well and frame/sheetmetal under there

I ordered parts:

Fuel tank

SS brake lines

Front calipers

Throttle cable

Choke cable

Hood latch cable

Inner and outer tie rod ends and boots

I stripped all the brake lines (rubber and metal) out of the car so I can replace them.

I stripped all the fuel lines (rubber and metal) out of the car for the same reason.

The car is equipped with 13" x 5" (or are they 5.5" steel wheels and comes with a 145/70-13 tire.

steel wheels and comes with a 145/70-13 tire.

I know someone who will widen the wheels for me. I will go with 8" wide rim on the rear and 6" wide on the front.

The tires I will go with are Toyo Proxes R888 in a 225/45-13 rear and a 205/60-13 front. I imagine I will have some clearance issues. I will address those (with a cutting torch, hammer, and welder ) when everything is bolted up.

) when everything is bolted up.

A hayabusa is a 1300cc Suzuki motorcycle. The 1.3 motor and 6 speed trans assembly weighs less than 200lbs. As I posted earlier, I should see 550hp when finished.

Comments

This thread was donated to our website to be preserved. If you want to message the author, please click the source link to contact.

Posted by diyauto on 8/25/21 @ 1:32:42 PM

This is a great build with so much time and effort put into recording in words and pictures. Can you help me with this question please, Is the top arm inner pivot point is in the same place as the original pivot point? Regards Davy

Posted by DavyF on 4/16/20 @ 6:44:51 PM