You must be logged in to rate content!

5 minute(s) of a 171 minute read

6-12-2010

Wide Ratio Gearbox And 1380 Engine Build

Compliments of AndyMiniMad @ http://www.theminiforum.co.uk

6-12-2010

I have NOT done this before but im going to give it a go. Do NOT take this info as the diffinitive guide because it isnt. Just me and a desire to have a go. Will post pictures with every step and will let you know if it works..

So we start with a stripped out and chemicaly cleaned box.

By the way all the bits are standard and in no way modified.. I just like taking things apart and rebuilding them..

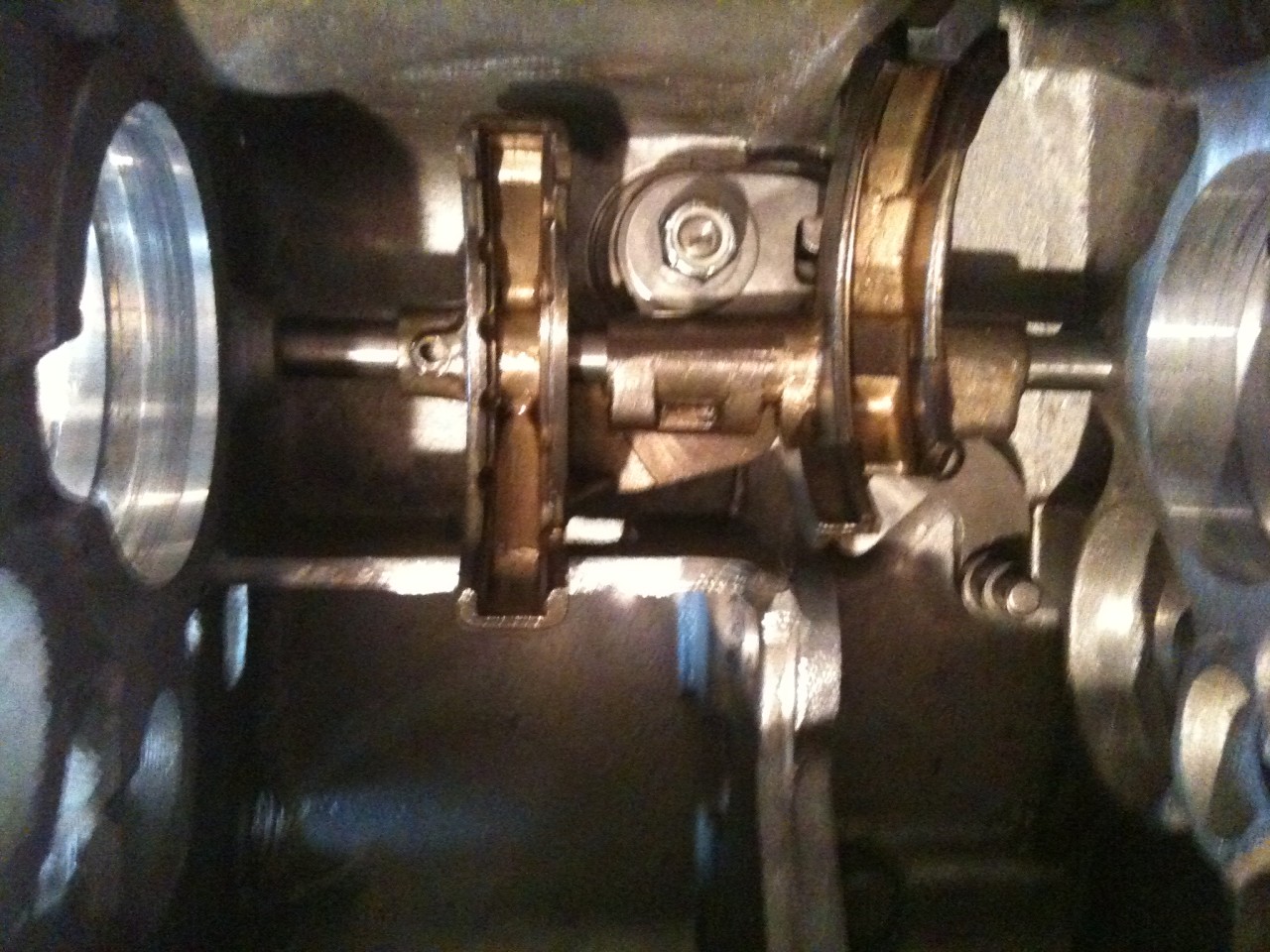

These bits are the selectors and shafts. In the order I removed them. When putting back in work from top to bottom

Will post next bit next weekend..

Thanks Guess-works Ill start again with the gasket removed. Just so every one knows im not tightening stuff up on this build for exactly the reason guess-works says. I am not going to use this box after the build but am just having a go before attempting to build a (special box) for my 1380 project.

This one.

I will start a new thread on that build once the block and head come back from the workshops.

Glad you are watching this Guess-works because im gonna need some bits.

6-13-2010

Here we go then..

I have cleaned the gasket off now so can start again.

The selector shafts.

One insde the other.

Once the shafts are in the box i started building up the selector forks. the bottom one is for the reverse gear and should engage with the key at the end of the shaft.

Then I built up the other selector forks in the order shown before.

once done you should be able to move the shaft in and out and see the forks moving you can twist the shaft to engage the individual forks.

The next bit is to insert the sleave, spring and ball bearing. these bits stop the shaft from moving more than is required when engaging the gears. also provide the positive feel of the engagement when selecting. These bits will fall out of there housing as you move the box about so i just put a bit of masking tape over to hold them in.

Dont really know what the proper name of these bits are but I am calling them the selectors.

The shaft goes in from this end and its important to put the end with the hole in first. Place the first selector on the shaft and make sure the groove at the bottom engages with the selector fork.

Then place the last selector on and line up the hole with the hole in the shaft. It also needs to engage with the selector fork.

Once its all lined up insert the roll pin through the selector and shaft, its a tight fit!!

I have been cleaning each part as I am fitting them with a good quality degreaser. the bits might look clean but its amazing how much dirt you remove.

Then a bit of oil and in the bits go.

Thats it for this week.

Nice details!

Posted by Diggymart on 5/20/20 @ 6:21:55 PM