You must be logged in to rate content!

3 minute(s) of a 92 minute read

8-31-2009

Turbo LS1 240z Build

Compliments of sq_creations @ forums.hybridz.org

8-31-2009

I purchased this 240z from Lason on here. It has alot of stuff I was planing to do to a 240z once I found it. I got it for a reasonable price and have a great car to start my new project.

The Borg Warner s480

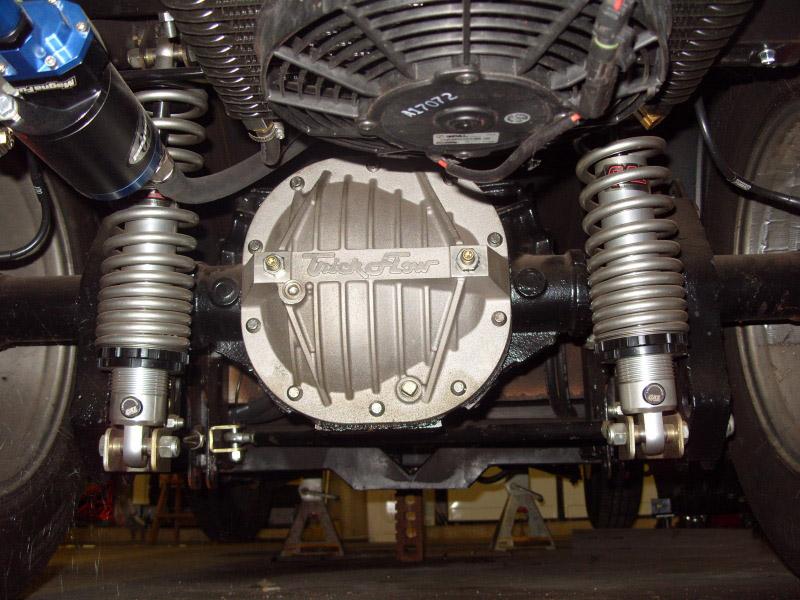

The engine was in pieces when I got it. I have about 60% of the engine and I'm starting to get parts now. Below you see the bare block I am tring to piece together. Also the new Wiseco pistons, Manley rods, Melling Oil Pump, Trickflow timing set, and some used Comp Cams Valvesprings.

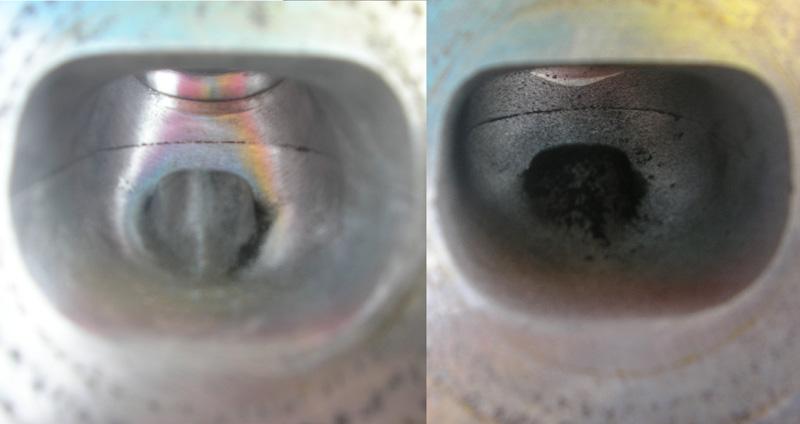

I started working on the heads this week. I pulled the valvesprings out because I plan to upgrade them. The head wasn't as clean as I hoped after being hot-tanked so I pulled the valves out and started scrubing. Then I decided the casting need to be smoothed out a bit a the valve could stand to be lapped. I have one head cleaned up but still have the other to do.