You must be logged in to rate content!

5 minute(s) of a 251 minute read

11-26-2011

1971 Speedipus Rex

Compliments of dangina @ www.protouringmopar.com

11-26-2011

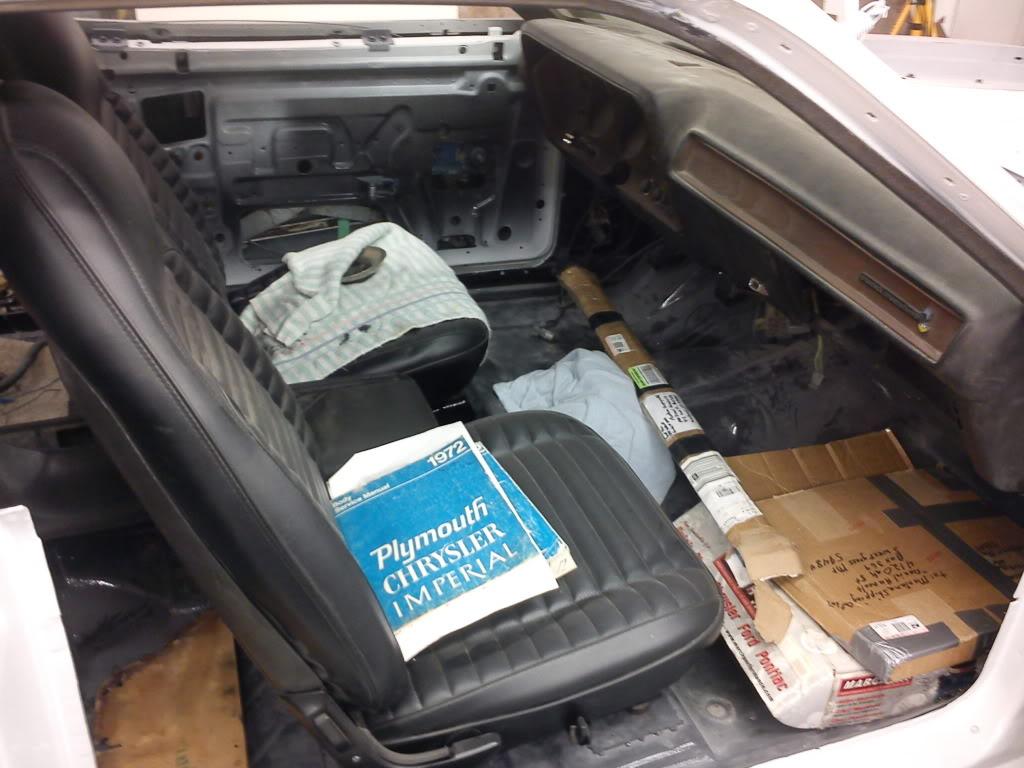

Finally with winter here and my other car in a new location - I have lots of room to start on my new project - a 1971 Plymouth Roadrunner. It's a 383 manual 4 speed with 276 gears and about 786269 miles on the odometer. Black Bucket seat interior with low opitions - I will give you more specs on the car when i can get through all the boxes to find the Vin tag - I believe I'll be the third owner of the car - last registered in 2001 - Previous owner did a bunch of body work to the car, Por-15 the whole underside and interior and never got around to finishing the project. My parents picked it up as a wedding gift for my Wife and I, The car has a huge significance to our family as it was the same car my dad had when i was born and sold it later when I was 4 (although his was a 72). I have always wanted to do a runner the same like my dad had back when i was a kid - he had a 2 tone paint scheme:

(I'll post the pics here later)

I'll be using the car to drive as much as possible during the year - with some autox and roadracing on the side - I've been busy doing the autox, dirt track, drifting and roadcoarse the last 5 years and always dreamt what it would be like to create a runner I have always wanted to have - the handling of todays cars with yesterdays looks, While adding one or two of my personal touches. I hope you like it!

Heres what i get to start off with:

Currently waiting for parts but here is my parts list so far (will add as more parts come in):

470ci stroker kit from Muscle Motors built locally by Performance Powertrain, Edlebrock RPM heads, Edleborck RPM Intake, Comp Cams XE285HL, Comp cams ultra pro magnum rockers, Milodon billet oil pump and cover, Milodon road race pan, QFT 830 4 bbl Carb with annular boosters and mechanical secondaries and electric choke, March Aluminum pulley set.

68 Camaro ABS front spoiler

69 Camaro fiberglass rear spoiler

8.75" backbraced with 489 case 3.55 gears Eaton True Trac

AAR Quality Fiberglass hood with air grabber

ABS chin whiskers

Afco leaf spring sliders

AndyF 13" Viper big brake kit from doctor diff w/drilled slotted rotors

AndyF stainless MC shield

AndyF stainless starter shield

AndyF LCA braces

ASD hydraulic ebrake Pistol grip conversion

Auto Rust Technicicans Torque boxes

Boregson large sector PS box with coupler

Custom tie rod sleeves 11/16" by Brads70

Custom subframe connectors 1x3" steel

Custom 1.75" DOM rad brace

Custom 1.5" DOM inner fender braces

Custom torsion bar brace

Custom hydraulic clutch conversion with 7/8" wilwood master cylinder and 7/8" slave cylinder

Doctor Diff 11.7" loaded cobra calipers rear disk brake kit with custom timken bearing and ebrake kit

Doctor Diff 15/16" aluminum master cylinder

Dougs 2.5" electric exhaust cutouts

Energy Suspension Polyurethane bushings

Enkei 18x9.5 +15 Black RPF1's with 245/45/18 Michelin Pilot Sport A/S3

Firm feel Fast ratio Pitman and Idler arm with upgrade roller bearing kit

Firm feel 1.12 torsion bars

Firm feel nylon control bushings

Firm feel greasable control pins

Firm feel 2" rear leaf spring brackets

Headman headers 78030

Hella H4 headlight housings

Hella H1 headlight housings

Hellwig tubular front sway bar 1.25"

Hellwig rear adjustable sway bar 7/8" with adjustable solid endlinks

Hotchkis Front geometry corrected tubular upper A arms

Hotchkis Heavy Duty rear leaf spring brackets

Hotchkis Adjustable Strut rods

Hotchkis Heavy Duty front sway bar bushing brackets

Howe 11/16" tie rod ends with 5/8" stud bumpsteer kit and spacers

Hypercoils rear leaf springs (200lbs)

Magnumforce 2" Dropped spindles

Moog problem solver balljoints

Moog tie rod ends 11/16"

Moog K750074 front endlinks

Mopardude custom gas tank

QA1 double adjustable shocks

Science Friction clutch ,pressure plate and Lightened steel flywheel

Stitch welded the whole underside of the car

TTI 2.5" X-pipe exhaust

Wilwood proportioning valve

I'm sure i'm forgetting more parts i have bought or will buy - I'll keep adding to this list so stay tuned!