You must be logged in to rate content!

14 minute(s) of a 297 minute read

7-16-2013

xluben's FogTurbo Bugeye | NF | 800+ WHP | 2002 WRX | 6766 | IAG Closed Deck 2.5L |

Compliments of xluben @ nasioc.com

7-16-2013

Car: 2002 Subaru WRX

Engine: EJ20 2012 STI EJ257

Turbo: TD04 VF39 STX 71 Kinugawa TD06H 60-1 Precision 6266 Precision 6766 (KillerB/Fobia Low Mount)

Transmission: 5MT 2012 STI 6MT

Body Style: Sedan

Color: Platinum Silver Metallic

Event: MAPerformance Proving Grounds

Location: Brainerd International Raceway (MN)

Ambient Temp: ~60°F

Elevation: ~1,200ft (DA: 1,335ft)

Weather: Sunny and Clear

Tires: 26" Mickey Thompson ET Street Radials on 15x7" +35 Rota Slipstream Wheels

Car: 2002 WRX Sedan

Tuner: Nuke @ NF Performance

Transmission: 2012 STI 6 Speed

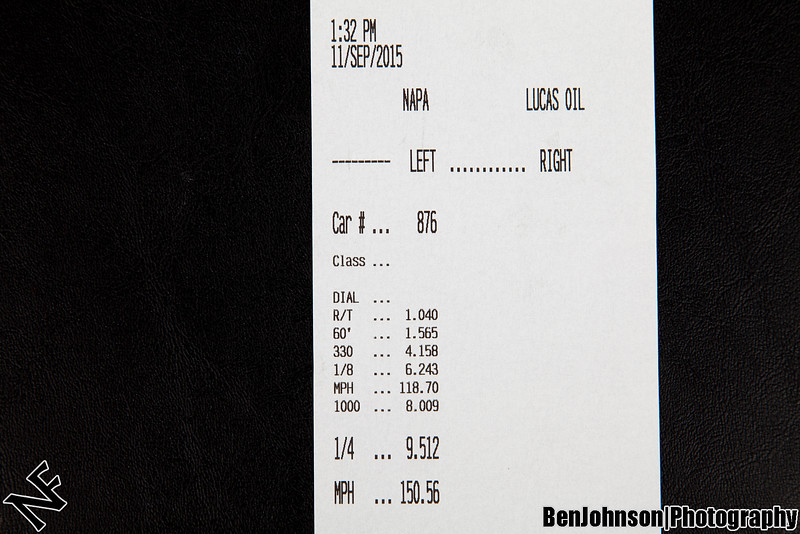

1/4 Mile ET: 9.51s

1/4 Mile Trap: 150.5mph

60': 1.56s

Target Boost: 43psi

Target AFR: 11's

Fuel: E85

9.5s @ 150mph @ 43psi on E85

Other Photos:

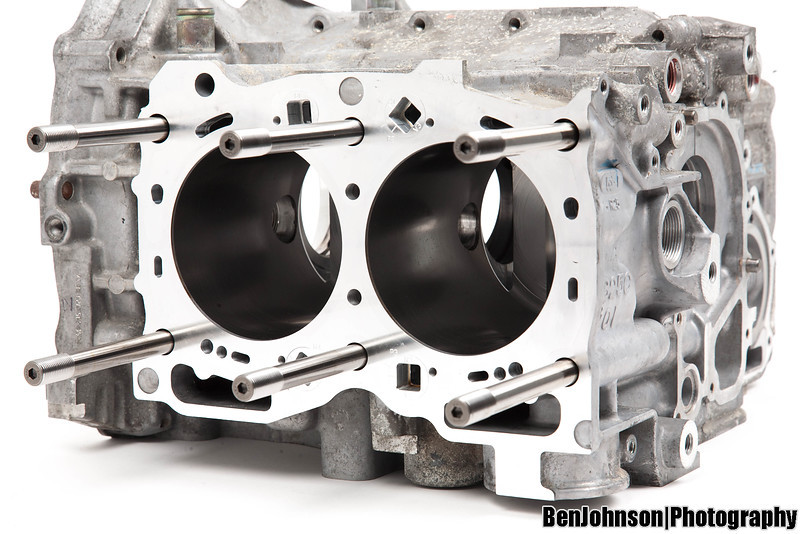

Engine:

- IAG Closed Deck 2.5L Case

- IAG 1/2" Head Studs

- OEM Subaru Crank

- JE Pro Seal Head Gaskets

- JE 99.75mm Pistons

- Manley Turbo Tuff I Beam Rods

- King Rod and Main Bearings

- OEM 2012 STI Heads (Running Non-AVCS)

- Kelford 199-L (282) Camshafts

- GSC Beehive Springs w/Retainers

- GSC Valve Seals

- Aluminati Solid Billet Motor Mounts

Intake/Exhaust/Fuel:

- Precision 6766 Turbo

- KillerB EL Header

- Fobia Fab Modified for FogLight Mount

- Fobia Fab Fender Exhaust Dump

- Fobia Fab Oil Sump

- TurboWerx Exa Pump Mini Oil Scavenge Pump

- Custom AN Oil Return Lines/Fittings

- Treadstone FMIC

- TurboSmart 40mm HP EWG

- TurboSmart Race Port BOV

- TurboSmart FPR 1200

- GrimmSpeed MBC

- Walbro 465 Fuel Pump

- DW300 Fuel Pump

- ID2000cc Injectors

- IAG Fuel Rails and Lines

- Treadstone 4" Velocity Stack

Drivetrain/Transmission

- OEM 2012 STI 6MT

- DSS CF Driveshaft

- DSS 800HP Rear Axles

- OEM STI R180 Rear Diff

- OEM 2004 STI Front Axles

- Anarchy Motive Shift Knob

- Kartboy Short Shifter

- Kartboy Front Shifter Bushings

- Karboy Rear Shifter Bushings

- Aluminati Solid Billet Tranny Mount

- Aluminati Solid Billet Pitch Stop Mount

- ACT HD Pressure Plate

- ACT 4 Puck Unsprung Disk

Suspension/Wheels:

- OEM 2002 WRX Wheels (Winter)

- 205/60R16 Blizzak WS70 Tires (Winter)

- 15x7" +35 Rota Slipstream Wheels (Summer)

- 235/60R15 Mickey Thompson ET Street Radial Tires (Summer)

- 15x7" +35 Rota Slipstream Wheels (Track)

- 26x8.5" Hoosier Slicks (Track)

- 02 WRX Struts

- Eibach Pro Kit Springs

Interior/Electronics:

- MapDCCD Differential Controller

- MapDCCD Wheel Speed Signal Processor

- ProSport EVO Boost Gauge

- ProSport EVO Oil Pressure Gauge

- AEM Wideband O2 Gauge

- Odyssey Slim Battery

Exterior:

- RS Flat Hood

- OEM Fog Light Covers

- Removed Rear Wing

2013 Updates:

07/14/13 - 2002 Silver Bugeye WRX (Mileage: 185k)

07/20/13 - Interior Photos

07/20/13 - Engine Bay Photos

07/21/13 - Struts, Uppipe, Crosspipe, Downpipe Photos

07/21/13 - Header, Uppipe, Turbo, Downpipe Photo

07/23/13 - Stock Baseline Virtual Dyno and Video

07/26/13 - DIY Wood Ramps

07/27/13 - TMIC, Splitter, Scoop, Exhaust Photo

07/29/13 - STI Fuel Pump Hanger and Walbro 255

07/30/13 - Round 1 of Mods (Bolt On's) - Part 1

07/30/13 - Round 1 of Mods (Bolt On's) - Part 2

08/02/13 - 2.0L, 5MT, VF39, Pump Gas Virtual Dyno

08/03/13 - 2012 Forester Wheels

08/03/13 - 2.0L, 5MT, VF39, Pump Gas Video

08/14/13 - 2012 STI Motor and Tranny Pull

09/13/13 - New Garage - Full

09/13/13 - New Garage - Empty

09/16/13 - 2.0L, 5MT, VF39, E85 Virtual Dyno and Video

09/20/13 - 2.0L Motor Pull

09/24/13 - New Garage CFL Lighting

09/25/13 - Organized Garage

09/27/13 - 5MT to 6MT Swap

10/03/13 - Photo Studio and Beats by Dre

10/11/13 - MapDCCD and Progress Photos

10/14/13 - DCCDPro vs. MapDCCD Comparison

10/23/13 - Craftsman 3/8" and 1/2" Impact ptI

10/23/13 - Craftsman 3/8" and 1/2" Impact ptII

10/30/13 - Progress Photos

11/10/13 - Steam STX 71 (TD06SL2+GTX3071R) Turbo - Rotating

11/01/13 - Steam STX 71 (TD06SL2+GTX3071R) Turbo - Photos

11/01/13 - Turbo Swap, Steam STX 71 (TD06SL2+GTX3071R) Turbo Installed

11/01/13 - Gojo Hand Cleaner

11/07/13 - AMR Inlet, MAW Plastic TGV's, ID2k, Injectors

11/09/13 - 2.5L Motor Install Part 1

11/23/13 - 2.5L Motor Install Part 2

11/23/13 - 2.5L Motor Install Part 3

11/30/13 - Harbor Freight Tool Chest and Tool Cart

12/01/13 - Steam STX 71 (TD06SL2+GTX3071R) 25psi E85 Tune - 427WHP / 413WTQ

12/05/13 - GrimmSpeed GD Hood Struts

12/06/13 - Interior (Indoor) Photos

12/09/13 - Interior and Exterior (Outdoor, Winter) Photos

12/19/13 - 2.5L, 6MT, STX71, E85 Video

2014 Updates:

01/09/14 - TurboXS BOV Studio Photos

01/10/14 - TurboXS FMIC Kit Studio Photos

01/18/14 - Front End Removal

01/29/14 - FP Turbo Oil Feed Line

02/04/14 - TurboSmart CompGate 40 EWG

02/06/14 - COBB Catback Exhaust

02/08/14 - OEM Foglight Covers

02/10/14 - DEPO Headlights

02/13/14 - RacingLine Shirts and Shoes

04/18/14 - Installed Uppipe

06/06/14 - Installed EWG and Turbo

06/09/14 - Installed FMIC

06/09/14 - FMIC Install Details

06/10/14 - FMIC Fitment Issues

06/11/14 - Installed Hood and Downpipe

06/13/14 - Installed COBB Exhaust and Removed Charcoal Canister

06/16/14 - Installed Wheels/Tires, Fixed Oil Leak, Started Car

06/16/14 - Turbo Oil Feed Leak Details

06/16/14 - First Outdoor Photos with FMIC and 2011 WRX Wheels

06/16/14 - Federal 595 RS-R 235/45R17 Tire Bulge

06/18/14 - Park Photos with FMIC and 2011 WRX Wheels

06/18/14 - STX 71 - FMIC - EWG - 26psi E85 Tune - 452WHP / 389WTQ

06/21/14 - MAPerformance Proving Grounds 2014.1 - 11.58 @ 119mph

06/21/14 - MAPerformance Proving Grounds 2014.1 - Timeslips Photo

06/23/14 - MAPerformance Proving Grounds 2014.1 - 11.42 @ 122mph - 8k Launch Video

06/23/14 - MAPerformance Proving Grounds 2014.1 - Dragstrip Video - Broken Axle Video

06/24/14 - MAPerformance Proving Grounds 2014.1 - Photos

06/25/14 - MNSubaru Boom Island Meet

06/27/14 - PW JDM Bumper Quick Release Install

06/27/14 - Dead End Photos

06/30/14 - Interior and Exterior Photos

06/30/14 - Prodrive Front Lip Install

07/01/14 - Prodrive Front Lip Outdoor Cameraphone Photos

07/02/14 - Prodrive Front Lip DSLR Photos

07/02/14 - Bent Front Strut

07/02/14 - Eibach Spring Side Photo

07/02/14 - 02 WRX and 15 STI Photo

07/04/14 - 1 Year Before and After

07/05/14 - MN Cars and Coffee Photos

07/07/14 - Outdoor Farm Photos - Eibach Springs

07/07/14 - COBB Exhaust Video

07/09/14 - Dead End Photo w/Flare

07/15/14 - Cabin Air Filter Install

07/17/14 - Spark Plug Install

07/17/14 - DIY $10 Oil Pressure Relocation Install

07/18/14 - MapDCCD Wheel Speed Sensor (VSS) Install and Review

07/24/14 - BPV Hose and Speaker Delete and License Plate Relocation

07/24/14 - Park/Woods Photos

07/28/14 - STX 71 Turbo Sold

07/30/14 - Uppipe to Turbo Leak

08/04/14 - New Turbo Installed - Camera Phone

08/04/14 - Kinugawa TD06H 60-1 Turbo Info and Installed Photos

08/07/14 - Kinugawa TD06H 60-1 Turbo Virtual Dyno Results - 484WHP / 426WTQ

08/07/14 - Kinugawa TD06H 60-1 Turbo 50-100mph Video

08/08/14 - Kinugawa TD06H 60-1 Turbo 45-120mph Video

08/10/14 - Reverse Flow FMIC Mods

08/14/14 - WRX vs RS Hood Weight

08/15/14 - 04 STI BBS Wheels

08/16/14 - FMIC 45 deg Coupler and EL Header

08/18/14 - 04 STI BBS Wheels and WRX Hood Outdoor Photos

08/23/14 - ID2000 Injector Seals

08/27/14 - ELM Bluetooth Adapter and Torque App

08/28/14 - ProSport Boost Inline Filter Broken

08/28/14 - AP EL Header Speedo Video

09/04/14 - 112lb Weight Reduction Details

09/04/14 - Rear Bumper Beam Removal

09/05/14 - MAPerformance Proving Grounds 2014.2 - 10.99 @ 126mph

09/09/14 - MAPerformance Proving Grounds 2014.2 - 1/4 Mile Video

09/09/14 - MAPerformance Proving Grounds 2014.2 - GTR Roll Race Video

09/10/14 - MAPerformance Proving Grounds 2014.2 - Other Roll Race Video

09/18/14 - KillerB Header Install

09/22/14 - KillerB Header Speedo Video

09/23/14 - Weekend Update (Stumble Fix)

09/26/14 - AccessPort V3 and 04 STI Tail Lights

09/29/14 - RS Motors Mustang Dyno - 457WHP / 422WTQ

09/29/14 - 60-1 vs. HTA68 vs. Stock Dyno Comparison

09/30/14 - Parking Ramp Photos

10/01/14 - AEM 3.5 Bar MAP Sensor Install

10/01/14 - RS Motors Mustang Dyno Video

10/04/14 - Stock 02 WRX Wheels and Blizzak WS70 Tires

10/06/14 - Outdoor Photo with 02 WRX Wheels

10/07/14 - DSLR Photo with 02 WRX Wheels

10/10/14 - PTE 6266 and Toy Bugeye

10/10/14 - Toy Bugeye Photos

10/13/14 - Rock Falls Drag - 10.98 @ 128mph on Snow Tires

10/16/14 - Rock Falls Drag - 60' vs. ET vs. Trap Video

10/23/14 - Rock Falls Drag - Data Log Plots

10/23/14 - Parking Ramp - No Bumper or Hood

10/31/14 - KillerB and PTE 6266 Photos

11/04/14 - Stock Location Parts FS

11/07/14 - PTE Turbo Blanket

11/10/14 - Fobia Low Mount Header

11/10/14 - Fobia Low Mount Header pt II

11/12/14 - Fobia Low Mount w/PTE 6266 Test Fit

11/14/14 - Fobia Low Mount w/PTE 6266 Test Fit pt II

11/14/14 - BOV, Oil Pump, Oil Lines and Fittings

11/28/14 - Treadstone FMIC

2015 Updates:

12/01/14 - Treadstone FMIC Test Fit

12/12/14 - Speaker Brackets

12/22/14 - Treadstone FMIC Test Fit pt II

12/26/14 - Tire Rack, Snap On Swivel Sockets, Charger

12/27/14 - Pittsburgh Professional Flex Head Ratchet

12/27/14 - Ratchet Comparison Photos

01/21/15 - Fobia Low Mount Treadstone FMIC Modification

01/23/15 - Bumper Cut and Installed

02/03/15 - Fuel Lines and Fittings and Preliminary Oil Fitting List

02/03/15 - Oil Lines and Fittings and Oil Pump Mounting

02/08/15 - IAG Fuel Rails

02/08/15 - Garage Clean Up and Wastegate Mounting

02/09/15 - Velocity Stack and Oil Sump Mounting

02/12/15 - -12AN Oil Drain and Bumper Exhaust Dump Cutout

02/14/15 - 3/8" NPT to -12AN Fitting, Line Routing, and Exhaust Dump Trim

02/16/15 - Trimmed Exhaust Dump with Bumper Installed

02/17/15 - 1320Video Facebook Post

02/23/15 - TurboSmart FPR Cap Switch

02/23/15 - IAG Rails Installed on MAW TGV Deletes

02/24/15 - Installed Fuel Lines, Rails, Intake Manifold, Turbo Oil Feed, and Crankcase Vent

02/25/15 - Crankcase Vent Photo

02/27/15 - Mishimoto Radiator Photos

03/03/15 - Oil and Fuel Pump Wiring: Part 1

03/06/15 - Odyssey Slim Battery and Die Hard Charger Photos

03/06/15 - TurboWerx Exa Pump Mini Photos

03/08/15 - FogTurbo Bugeye Rolling Shots and Engine Bay

03/10/15 - Initial Tune and Radiator Hose Replacement

03/10/15 - Camera Phone Photos

03/11/15 - Parking Ramp Photos

03/11/15 - Parking Ramp Exhaust Video

03/12/15 - Proven Power Bragging Thread - Virtual Dyno Results

03/12/15 - Speedo Video and 50-100mph Comparison

03/12/15 - Speedo Video 50-100mph 7k Shift Comparison

03/13/15 - Anarchy Motive Shift Knob Photo

03/25/15 - Air Filter Comparison Photo

03/26/15 - Air Filters Installed Comparison Photo

03/26/15 - Parking Ramp Rig Shot

03/28/15 - Intake Filter Testing Results

03/28/15 - Enkei RPF1 Test Fit Photos

03/31/15 - Outdoor Photo with Stock Wheels

04/01/15 - RPF1 Spacer Install and Outdoor Photos

04/06/15 - RPF1 eBay Center Caps

04/06/15 - Cam Timing Changes and Comparisons

04/06/15 - Hoosier Slicks Test Fit Photos

04/08/15 - T-Brace Repair, R180, and DSS Axles

04/09/15 - T-Brace Repair, Header Photo

04/14/15 - Speedo Video and 50-100mph

04/18/15 - Rock Falls Drag Camera Phone Photos

04/20/15 - Rock Falls Drag - 10.36 @ 139mph on Street Tires

04/25/15 - Replaced Front Brake Rotors, Calipers, and Pads

04/25/15 - Slowing Down at the Dragstrip Video

04/30/15 - Dyno Tune - 666WHP on Dynojet

04/31/15 - Dyno Tune Full Details and Video

05/04/15 - Rig Shots with Eric V

05/09/15 - Seibon CF "RS Style" Hood

05/11/15 - Spark Plug and Grounding Upgrades

05/14/15 - GrimmSpeed Hella Horn Bracket Install

05/15/15 - Outfront Motorsport Alternator Relocation Bracket Install

05/15/15 - Gray Plasti Dip on RPF1

05/15/15 - Painted CF Hood and Photos of Wingless Trunk

05/18/15 - 04 WRX Cluster Swap

05/19/15 - 666WHP Updated 50-100mph Video

05/23/15 - Sold RPF1 - Stock Wheels Photo

05/29/15 - 26x9.5R15 Mickey Thompson ET Street Radials

05/31/15 - 26x8.5R15 Hoosier Slicks and 15x7 +35 Rota Slipstreams

06/02/15 - Brenizer Shot - Stock Wheels

06/03/15 - Sunset Shot - Stock Wheels

06/03/15 - Rota Slipstream 15x7" +35 Wheels

06/04/15 - 26x9.5R15 Mickey Thompson ET Street Radials and Rota Slipstream 15x7" +35 Wheels

06/05/15 - Slipstream and MT Installed - Cell Phone

06/05/15 - Slipstream and MT Installed - Daylight / DSLR

06/06/15 - Rock Falls Drag - 9.94 @ 139mph on Hoosier Slicks

06/10/15 - NF DCTC Photos - Part 1

06/10/15 - NF DCTC Photos - Part 2

06/15/15 - IAT Sensor, Fuel Filter, Aluminati Motor, Trans, Pitch Stop Solid Mounts

06/16/15 - ACT 4 Puck Clutch Disk Replacement

06/18/15 - Replaced Brake Light Bulb

06/20/15 - MAPerformance Proving Grounds 2014.1 - 10.2 @ 137mph

06/22/15 - MAPerformance Proving Grounds 2014.1 - Roll Racing

06/24/15 - MAPerformance Proving Grounds 2014.1 - 10.1 @ 140mph

06/26/15 - Melted Bumper / Dump Alignment

07/07/15 - PTE 6766 and DW300

07/17/15 - 6766 at DCTC - Initial Tune at 40psi and TurboSmart HP EWG

07/22/15 - 6766 at 35psi Speedo Video

07/27/15 - FlexConverter.com E85 Sensor

07/27/15 - Xluben's FogTurbo Bugeye Facebook Page

08/04/15 - New Motor Internals, Kelford 282 Cams, and Garage Photo

08/06/15 - Engine Internals and IAG Case Halves Core Shipment

08/07/15 - Motor Pull Video

08/12/15 - Yellow Bugeye Motor Pull Video

08/14/15 - IAG Closed Deck Machining Photos

08/19/15 - Gas Can Updates

08/20/15 - IAG Closed Deck Block Studio Photos

08/21/15 - GSC S1 Cams For Sale

09/10/15 - Motor Installation and DSS CF Driveshaft Photos

09/10/15 - Dyno Photos - MAPerformance Dyno - Tuned by Nuke at NF Performance

09/11/15 - 834WHP Dyno Plot, Packed up for Proving Grounds, and 9.5 @ 150mph

09/14/15 - MAPerformance Proving Grounds 2014.2 - 9.5 @ 150mph

09/15/15 - Motor Install Video

09/18/15 - Refurbished PTE 6766 Photos and Speedo Video

09/21/15 - Bumper Off, Dead End Photos

09/23/15 - Virtual Dyno Plot - 4th Gear

10/04/15 - Rock Falls Drag - 10.04 @ 148mph

11/16/15 - Removed MT Radials, Installed Stock WRX Wheels and Snow Tires, RS 6 Spoke Wheel Photos

11/20/15 - Stock WRX Wheels - Outdoor Photos

11/24/15 - Stock WRX Wheels - Parking Ramp Strobed

11/28/15 - MNSubiez Parking Ramp Rig Shots

11/28/15 - Heavy Duty Garage Shelf

12/02/15 - S&W 10 Point Roll Cage

12/05/15 - Kirkey Pro Drag Aluminum Seats

12/08/15 - Kirkey Seat Covers

12/10/15 - NRG Quick Release Steering Wheel Hub

12/10/15 - Mike Parking Ramp Rig Shots

12/16/15 - Kirkey Seat Mounting Brackets

12/18/15 - Kirkey Seats Mounted in Car

12/22/15 - 9.5 @ 150mph Video with Speedo Overlay

2016 Updates:

01/04/16 - G-FORCE 5 Point Harness

02/01/16 - Indoor Photo of Installed Cage

02/07/16 - Updated Kirkey Seat Mounting

02/07/16 - 10 Point Roll Cage Outdoor Photos

02/07/16 - 2015 Quickest and Fastest Subarus Video

02/19/16 - RJS Window Net and Mounting Kit & Advanced Chassis LLC Seat Back Bracket

03/02/16 - Silver Enkei RPF1 17x9" +45 with hubcentric rings and Honda centercaps

03/16/16 - 17x9" RPF1 with 245/45R17 M&H Drag Radials

03/17/16 - Work Parking Lot Photo and Idle Video

03/19/16 - RPF1 Installed Photos

Picked up this car as the new project. I spent the last month or so looking for a car that I could build up. Now that I have a 2012 Forest for a daily driver this will be a weekend/project car only. I wanted to start with a cheaper base and had my eye on a Bugeye WRX as my top choice. I wouldn't have minded something newer, but the cost was generally quite a bit more. The slightly lower weight on the Bugeye sedan was also appealing. I was even looking for something with a blown motor or tranny to save money. My search was nationwide. I e-mailed/PM'd/texted many people and looked/drove a few cars.

Eventually I was pointed to this one by a friend. It was semi-local and running. It had a new timing belt, water pump, clutch and heads put in this spring. The interior is clean (even has a single DIN stereo). There are a few mechanical things I need to look into and the exterior has some dents (quite a few in the hood) and a little rust starting on the quarter panels, but overall it was in pretty good shape for a car of this age. And the fact that it was local and running saved me a decent chunk of money by not having to ship it.

The car has virtually no mods. Just the giant eBay hood scoop and the muffler cut off. Surprisingly it's not that loud (for having no muffler at all). No firm plans for the car yet. Still trying to figure that out. I would eventually like to make it fast

Here are some photos: