You must be logged in to rate content!

9 minute(s) of a 643 minute read

10-28-2010

xluben's 2011 WRX: Spec B 6 Speed and Rotated PTE 6266

Compliments of xluben @ nasioc.com

10-28-2010

|xluben's 2011 WRX | NF Performance | Project Dark Knight |

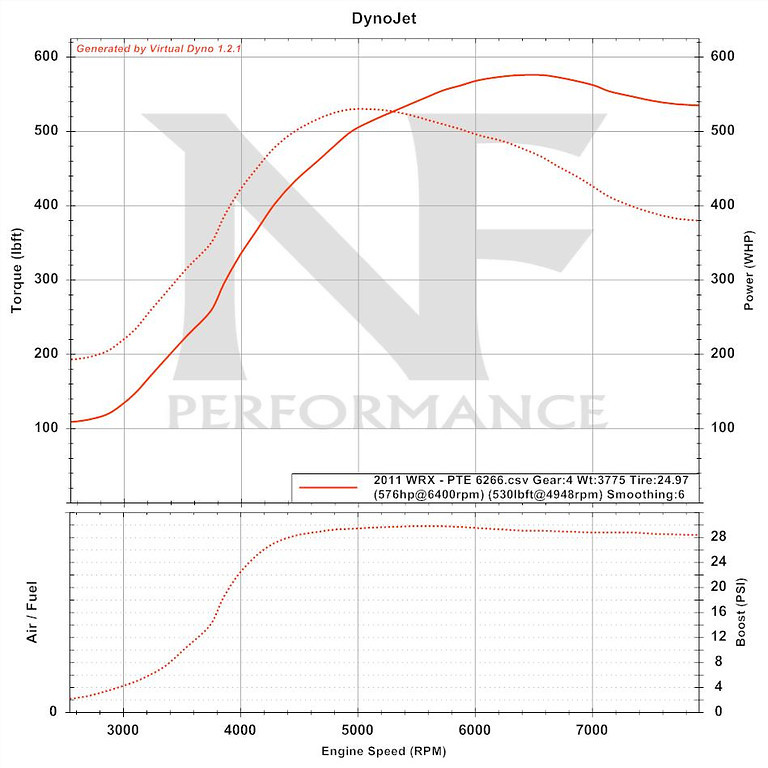

|Spec B 6 Speed | Rotated PTE 6266 | 576WHP / 530WTQ |

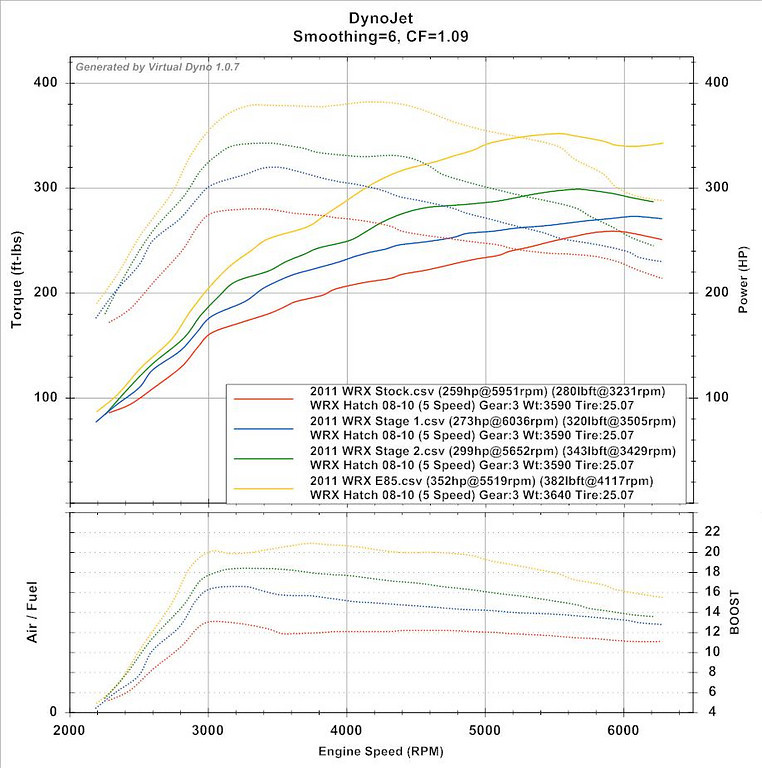

Dyno Plot:

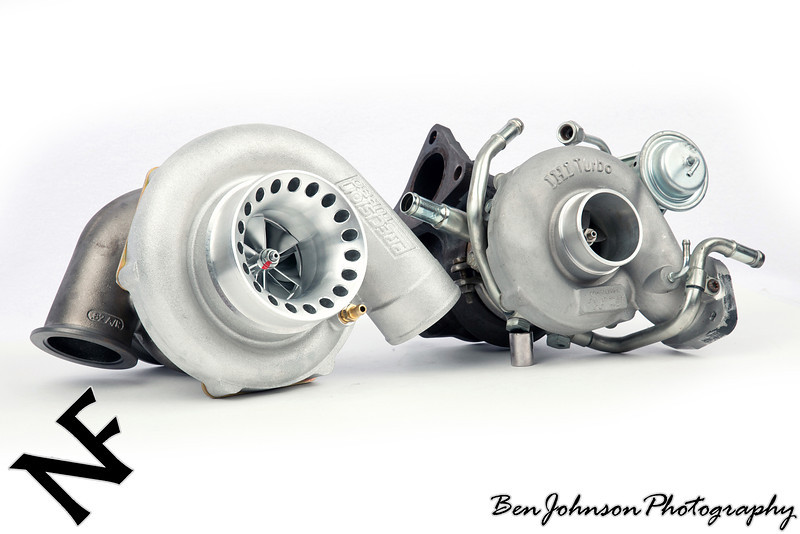

6266 vs. VF52:

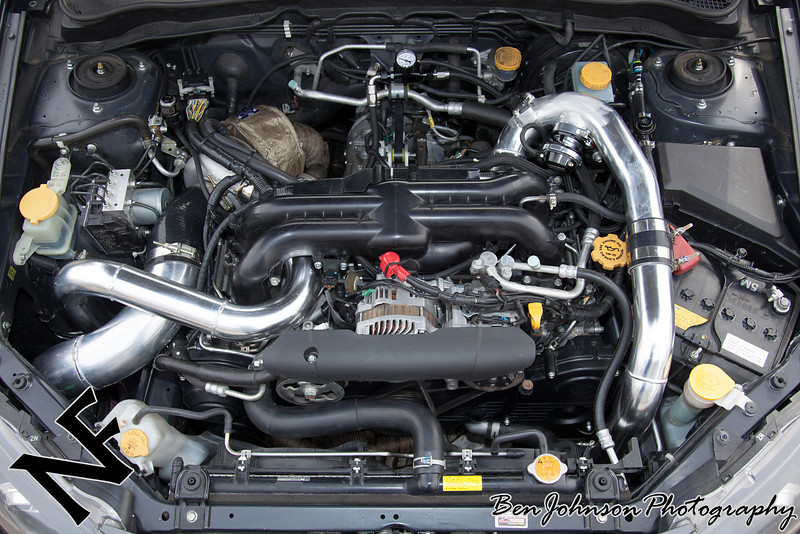

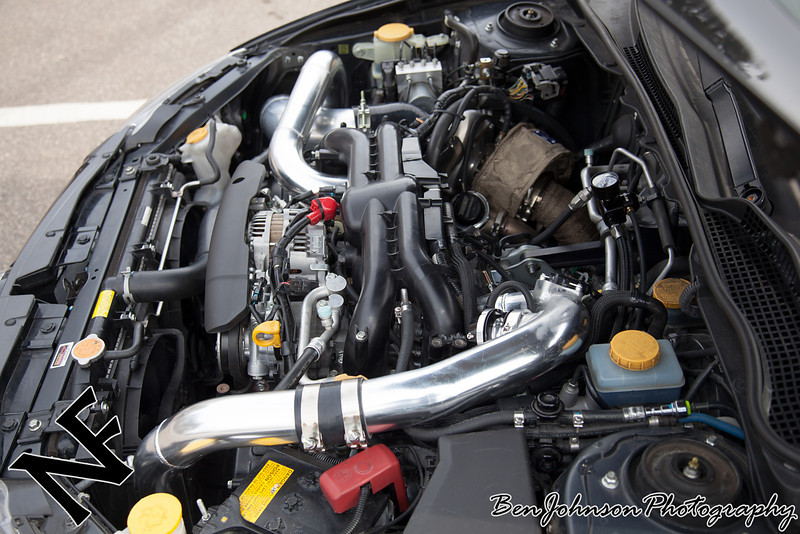

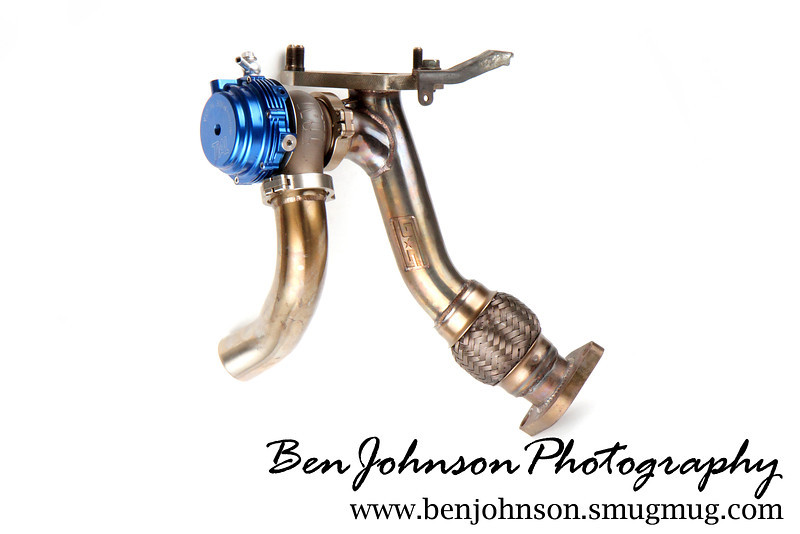

Rotated Turbo Setup:

Quick Pull:

Here's another video:

3rd Gear Pull @ 32psi (boost gauge goes wacky above 30psi)

2nd Gear Brake Boost, 3rd, 4th @ 30psi

50-100MPH is ~4 sec for the 3rd Gear Pull

60-130MPH is ~8 sec for the 2nd, 3rd, 4th Pull

Exhaust Video:

Engine:

- 703 Casting Case Halves

- Manley Turbo Tuff Rods

- Manley Coated Pistons

- Stock Subaru Crank

- ACL Race Series Main Bearings

- ACL Race Series Rod Bearings

- Balanced Rotating Assembly

- Covert Oil Pickup

- MAP H11 Head Studs

- TGV Deletes

- FujiK of NF Performance Head Porting

- GSC Beehive Springs

- Stock Valves

- Stock Cams

Intake/Exhaust/Fuel:

- PTE 6266 V-Band Journal Bearing Turbo

- Fobia Twin Scroll Header

- Fobia Rotated 1.5 Scroll V-Band Uppipe

- Fobia Rotated 3" V-BandDownpipe

- Fobia Rotated 4" Intake

- Fobia Rotated/SD FMIC Piping

- TurboSmart HyperGate 45mm EWG

- TurboSmart RacePort 50mm BOV

- COBB 3" Cat Back Exhaust

- FMS FMIC w/GS Thermal Coating

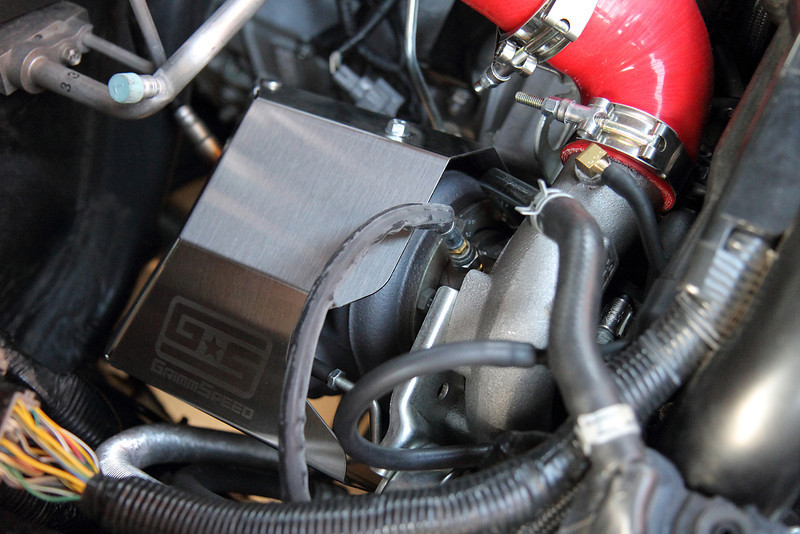

- GrimmSpeed MBC

- Walbro 465 Fuel Pump Hardwired

- FiveO Motorsports 1600cc Injectors

- Fuelab FPR at 55psi

- COBB AP Speed Density Tune

Drivetrain/Transmission

- 2011 STI 6 Speed Transmission

- Legacy Spec B High Speed Gears

- 08+ STI Shift Linkage

- Kartboy Shifter and All Bushings

- Anarchy Motive Heavyweight Knob

- ACT XT Pressure Plate

- ACT Unsprung 6 Puck Disc

- STI Clutch Fork

- STI Clutch Slave Cylinder

- Braided SS Clutch Line

- TIC Transmission Crossmember Bushings

- 08+ Impreza AT Driveshaft

- R160 3.54 Final Drive Rear Diff

- STI Starter

Suspension/Wheels:

- Enkei RPF1 17x9" +35 Wheels

- 255/40R17 Federal 595 RS-R Tires

- RCE Black Springs (Stock Struts)

- Whiteline 22mm Front Sway Bar

- Whiteline 22mm Rear Sway Bar

- RalliTEK HD Front Endlinks

- RalliTEK HD Rear Endlinks

- 2011 WRX Stock Wheels (Winter)

- 225/45R17 General Altimax Arctic Tires (Winter)

- GrimmSpeed Master Cylinder Brace

- StopTech SS Brake Lines

- StopTech Street Performance Brake Pads

- ATE SuperBlue Brake Fluid

Interior/Electronics:

- Defi Boost Gauge

- Defi Oil Pressure Gauge

- SMY Dual Gauge Cluster

- AEM UEGO Digital Wideband O2 Gauge

- Omni Power 4 Bar MAP Sensor

- Recaro ProRide Baby Seat

Exterior:

- V-Limited Front Lip

- Red Tail Light Overlays

- Flapatax Mud Flaps

- GrimmSpeed License Plate Relocation Kit

- GrimmSpeed License Plate Delete

- OEM Scoopless Hood

- VG Shark Fin Antenna

- Yakima Roof Rack

Chronological:

2011 WRX Purchased: 10/21/10

MODE Shifter: 11/03/10

SPT Exhaust: 11/07/10

Winter Wheels: 11/12/10

Stage 1 Tune: 11/18/10

COBB Downpipe: 12/19/10

Stage 2 Tune: 12/19/10

IPR TMIC: 1/14/11

Forge BPV: 1/14/11

Defi Boost Gauge: 1/15/11

SMY Dual Gauge Cluster: 1/19/11

Walbro Fuel Pump: 1/27/11

Kartboy Front Shifter Bushings: 1/29/11

DIY Seat Bolster Mod: 02/07/11

Kartboy Rear Shifter Bushing: 02/16/11

GrimmSpeed Master Cylinder Brace: 02/17/11

Red Tail Light Overlays: 02/19/11

Flapatax Mud Flaps: 02/26/11

AEM Cold Air Intake: 02/28/11

GrimmSpeed EBCS and MBC (Hybrid Boost Control): 02/28/11

Fiveo Motorsports 1200cc Injectors: 03/05/11

Custom E85 Tune: 03/05/11

Whiteline 24mm Adj. Front Sway Bar: 04/21/11

Whiteline 22mm Adj. Rear Swaybar: 04/21/11

RalliTEK HD Front Endlinks: 04/21/11

RalliTEK HD Rear Endlinks: 04/21/11

BC Racing Inverted Coilovers: 04/21/11

AEM UEGO Digital Wideband O2 Gauge: 05/23/11

Whiteline 22mm Adj. Front Sway Bar: 05/27/11

GrimmSpeed License Plate Relocation Kit: 06/02/11

Fast Motorsports (FMS) Front Mount Intercooler (FMIC): 06/07/11

OEM Scoopless Hood: 06/13/11

Yakima Roof Rack: 06/27/11

Invidia Q300 Exhaust: 07/22/11

Invidia Catless Downpipe: 07/22/11

Blouch 20G-XT-R Turbo: 9/17/11

GrimmSpeed License Plate Delete: 9/22/11

GrimmSpeed Turbo Heat Shield: 9/23/11

Gold 04 STi BBS Wheels: 09/28/11

KSTech 73mm Intake: 10/01/11

Tial MV-R 44mm EWG, GrimmSpeed Uppipe and Crosspipe: 10/13/11

Omni Power 4 Bar MAP Sensor: 02/06/12

Stock Exhaust: 02/18/12

Blown Motor - Cracked #2 Piston: 02/22/12

Built Shortblock: 03/05/12

TGV Deletes: 03/05/12

AMR 3" Hard Inlet: 03/05/12

Mach V Awesome 17x9" Wheels: 03/21/12

Dunlop Star Spec 255/40R17 Tires: 03/21/12

GFB 50/50 Hybrid BOV: 03/31/12

Turbo XS 50/50 Hybrid BOV: 04/05/12

ACT HD Pressure Plate: 04/06/12

ACT Street Light Flywheel 04/06/12

ACT Sprung 4 Puck Clutch Disc: 04/06/12

Dyno @ MAP: 462WHP / 492WTQ: 04/11/12

RCE Black Springs: 04/14/12

TurboSmart Kompact BPV: 04/18/12

StopTech SS Brake Lines: 04/18/12

StopTech Street Performance Brake Pads: 04/18/12

ATE SuperBlue Brake Fluid: 04/18/12

Koni Adjustable Dampers (Rear): 04/26/12

Koni Adjustable Dampers (Front): 04/27/12

besthaticouldo Shift Knob: 05/08/12

All-In-One Flip Key Mod: 05/16/12

In-Cabin MBC Relocation: 05/22/12

SPT Exhaust: 05/26/12

Blown 5 Speed - Stripped 3 Gear: 06/02/12

V-Limited Front Lip: 06/13/12

Stock Exhaust: 07/15/12

Forge BPV: 07/16/12

TurboSmart Dual Port BPV: 07/19/22

Removed Clutch Delay Valve: 07/22/12

Greddy Ti-C Catback: 08/10/12

PTP Turbo Blanket: 08/12/12

Hand Wash and Wax: 09/08/12

Invidia Equal Length Header: 09/25/12

PAR Straight Cut 2nd Gear: 10/14/2012

Kartboy Pitch Stop Mount: 10/14/2012

Cusco Motor and Tranny Mounts: 10/14/2012

Mach V Awesome Decals: 10/18/2012

2 Year Anniversary!: 10/24/2012

Stock Wheels and Winter Tires: 10/28/2012

Stock Exhaust: 10/28/2012

ARK GRiP Exhaust: 11/02/2012

PTP Lava Turbo Blanket: 11/10/2012

GReddy SP Elite Exhaust: 11/14/2012

Exhaust Comparison Photos: 11/18/2012

Kartboy Shifter Comparison: 11/20/2012

VG Shark Fin Antenna: 01/14/2013

Photos Before/After Editing: 01/16/2013

Recaro Baby Seat: 01/28/2013

17x9" RPF1 (Black Background): 01/31/2013

17x9" RPF1 (White Background): 01/31/2013

DCCD Pro Photos: 01/31/2013

STI 6MT Swap Info: 02/11/2013

New Motor and Rotated PTE6266: 03/22/2013

Forge BPV (1/14/11):

IPR TMIC (1/14/11):

Defi Boost Gauge (1/15/11):

SMY Clustermaker Dual Guage Cluster (1/19/11):

Walbro 255 Fuel Pump (1/27/11):

Kartboy Shifter Bushings (1/29/11):

DIY Seat Bolster Mod (02/07/11):

Kartboy Rear Shifter Bushing (02/16/11):

GrimmSpeed Master Cylinder Brace (02/17/11):

Defi Oil Pressure Gauge (02/17/11):

Red Tail Light Overlays (02/19/11):

Flapatax Mud Flaps (02/26/11):

AEM Cold Air Intake (02/28/11):

GrimmSpeed EBCS and MBC (Hybrid Boost Control) (02/28/11):

Fiveo Motorsports 1200cc Injectors (03/05/11):

Custom E85 Tune (03/05/11):

Whiteline 24mm Adj. Front Sway Bar (04/21/11):

Whiteline 22mm Adj. Rear Swaybar (04/21/11):

RalliTEK HD Front Endlinks (04/21/11):

RalliTEK HD Rear Endlinks (04/21/11):

BC Racing Inverted Coilovers (04/21/11):

AEM UEGO Digital Wideband O2 Gauge (05/23/11):

Whiteline 22mm Adj. Front Sway Bar (05/27/11):

GrimmSpeed License Plate Relocation Kit (06/02/11):

Fast Motorsports (FMS) Front Mount Intercooler (FMIC) (06/07/11):

OEM Scoopless Hood (06/13/11):

Yakima Roof Rack (06/27/11):

Invidia Q300 Exhaust and Downpipe (7/22/11):

Blouch 20G-XT-R Turbo (9/17/11):

GrimmSpeed License Plate Delete (9/22/11):

GrimmSpeed Turbo Heat Shield (9/23/11):

Gold 04 STi BBS Wheels (09/28/11):

Tial MV-R 44mm EWG, GrimmSpeed Uppipe and Crosspipe (10/13/11):

Completely stock Black 2011 WRX 5 Door: