You must be logged in to rate content!

19 minute(s) of a 82 minute read

1-23-2013

In the wiring box is a complete Pulsar 1.8L DE chassis harness, a DE Engine harness, a CA16DE engine harness and a cut section of a CA16DE chassis harness. The two ECUs are both DEs, one US DE from an 88 Pulsar and one Canadian DE from an 88 Pulsar. I should have the engine on a stand sometime this week, and the transmission is up in the air at the moment.

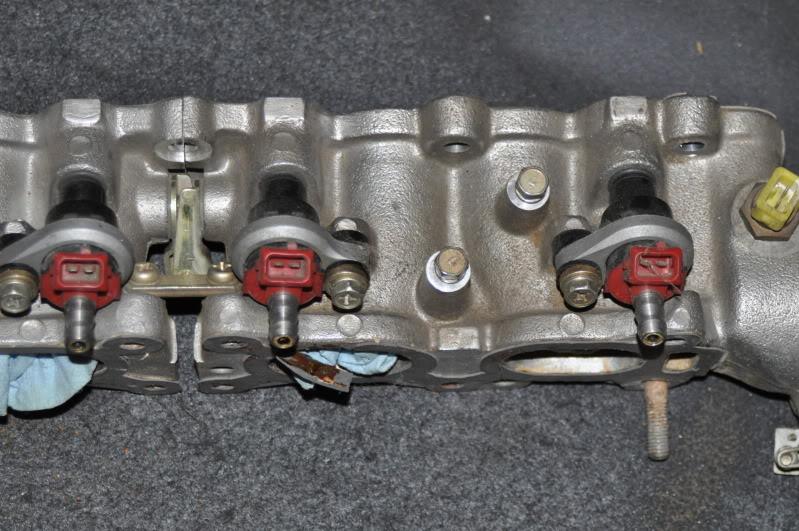

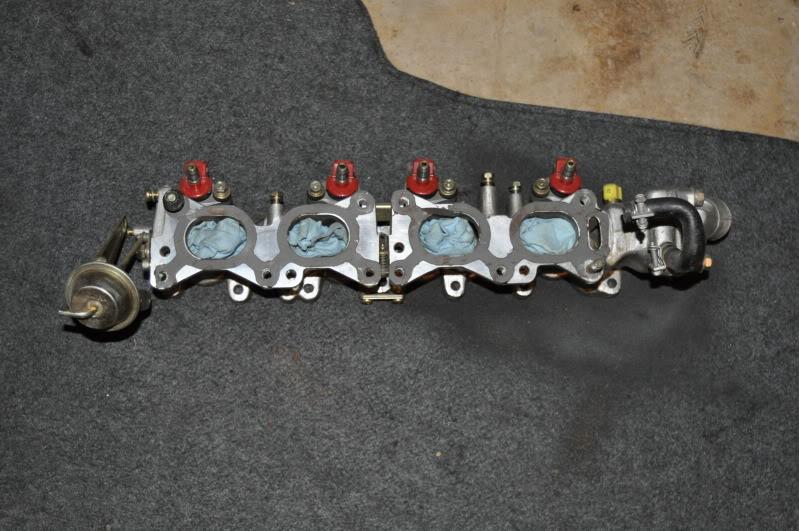

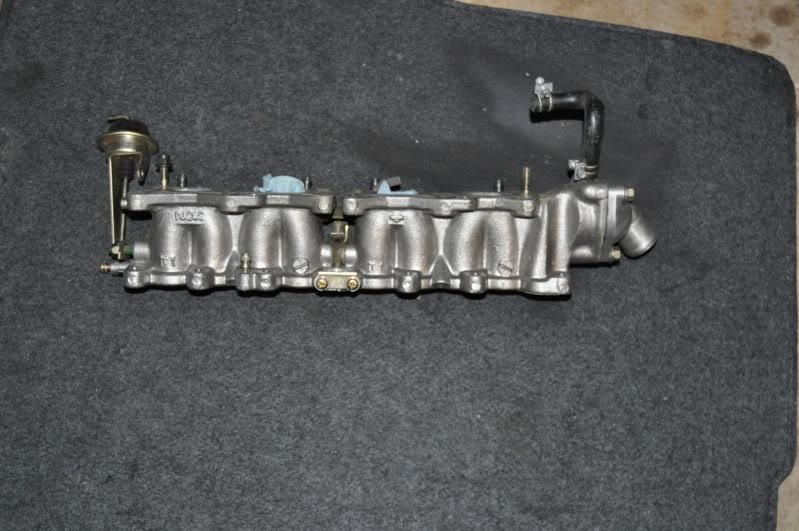

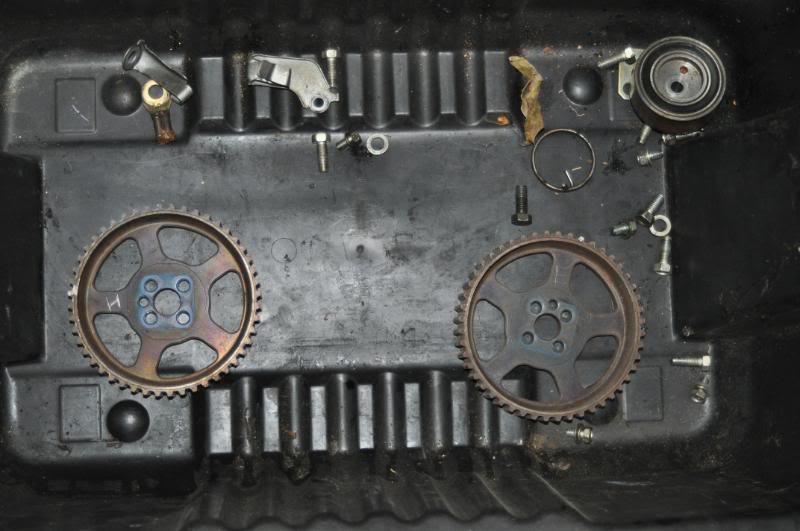

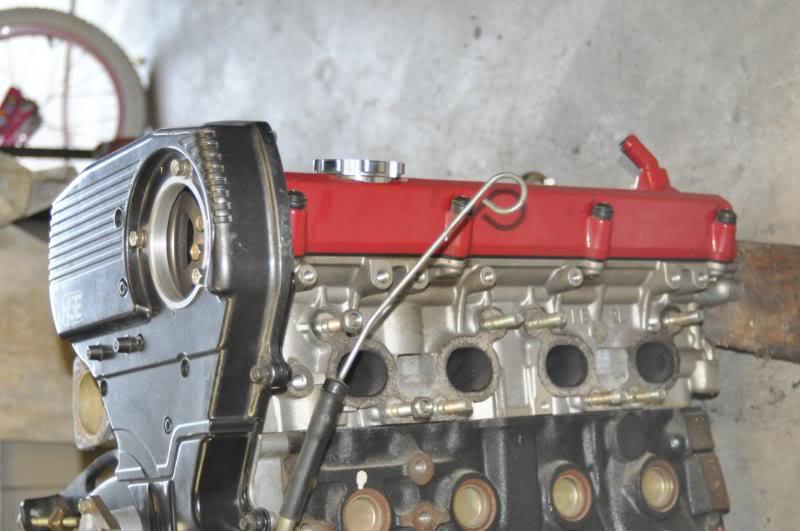

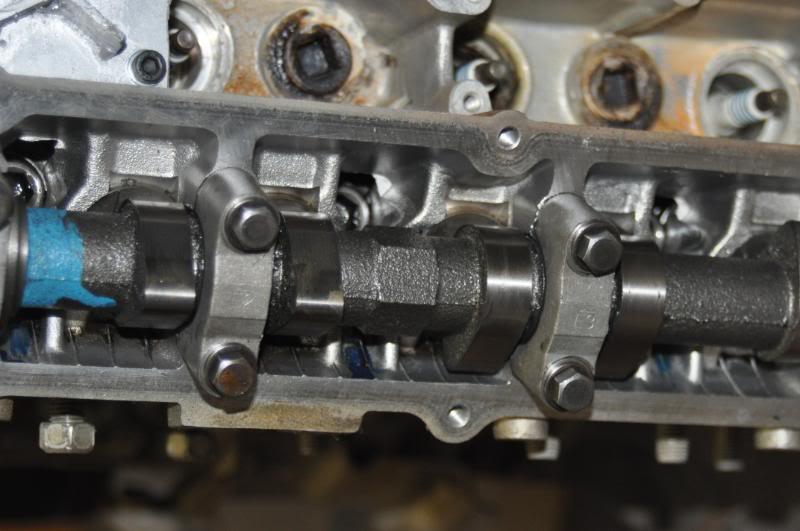

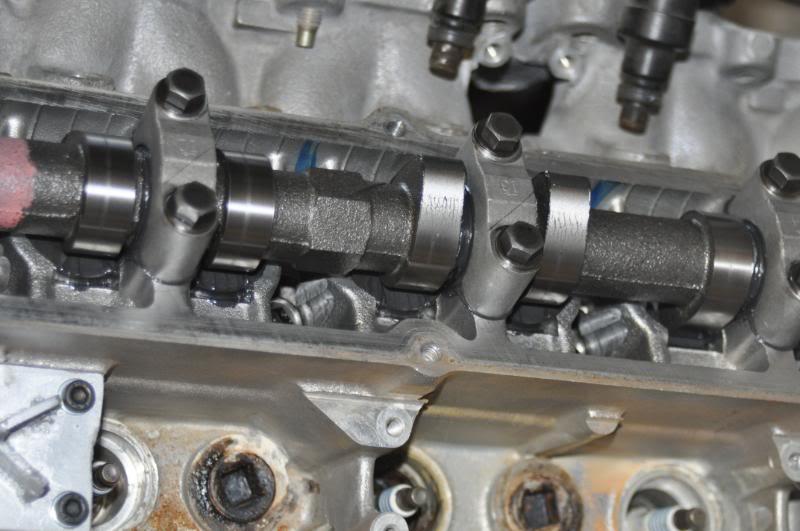

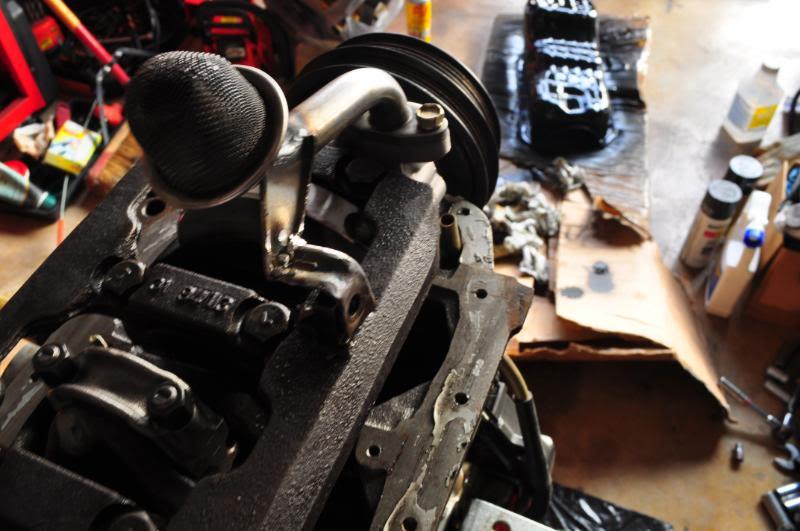

Here are some photos of the spare CA head I have. My dad traded a spare ignitor for the head...he ended up getting a complete head, cam gears, RWD intake manifold (with throttle body, injectors, fuel rail, etc.). Not bad. Still clearing space in the garage to bring the engine home. I need to make room for another engine stand.

My dad and I thought this would be pretty fun if it was actually put to use.

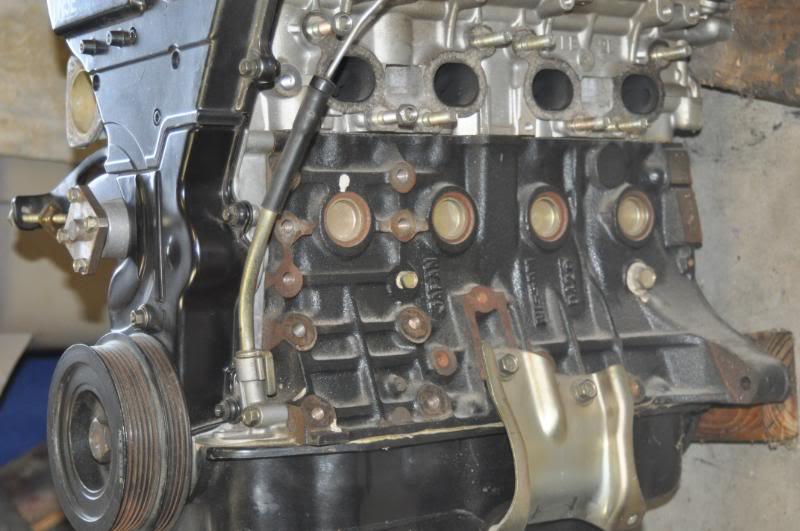

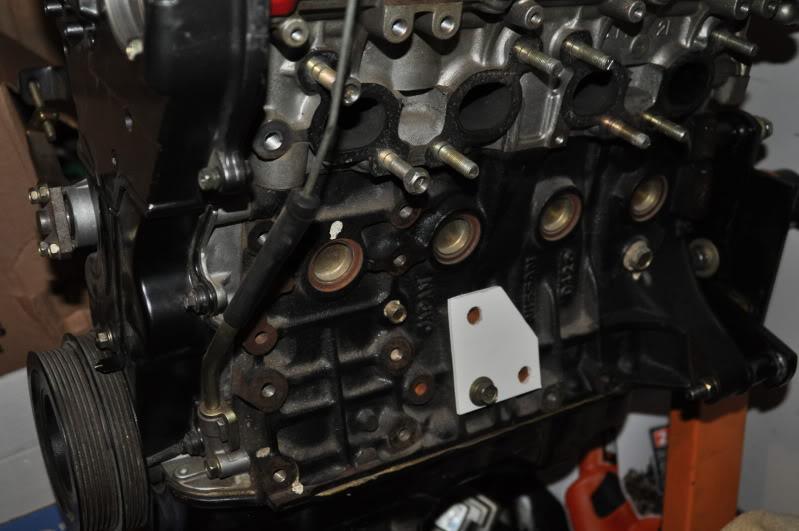

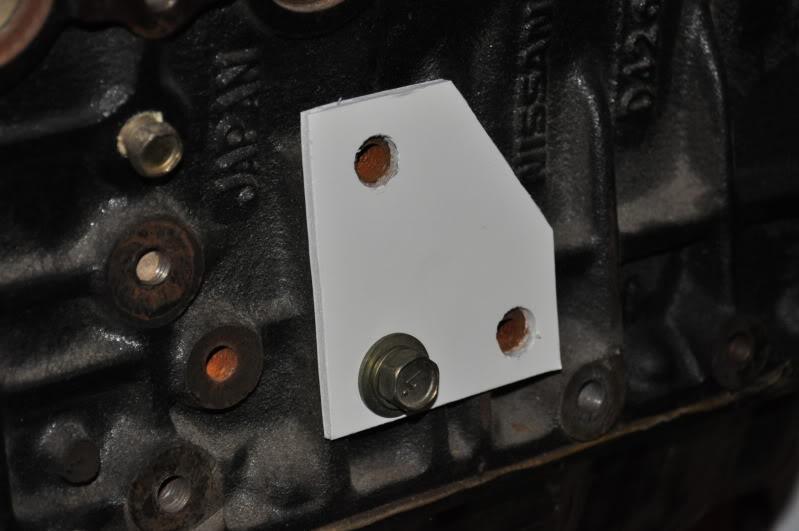

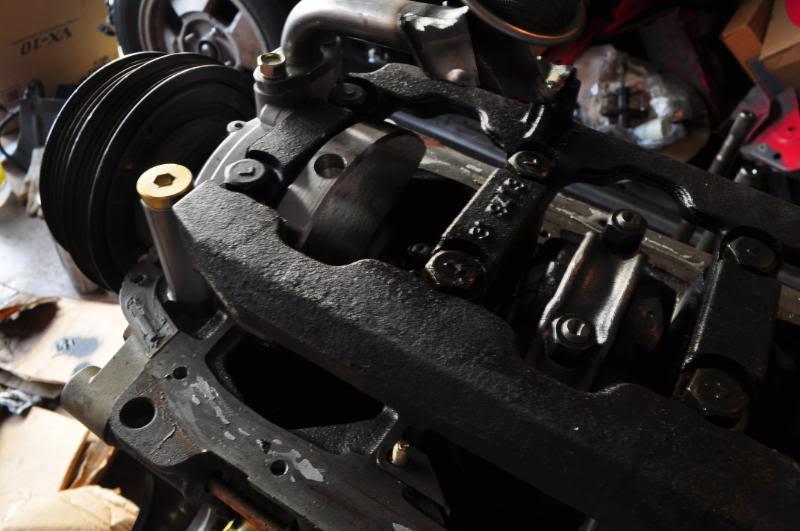

Here are some photos of the engine. I still haven't trucked it back to my garage to put on an engine stand though.

It looks fairly unused. When my dad got it back to his garage it still had a brand new factory oil filter on it, the oil that was still in the engine was extremely clean, the cams had no wear marks, the timing belt and all of the seals were brand new, all of the sensors were as near to new as the get, and the O2 sensor showed very little signs of use. It's literally as if the owner drove the car off of the lot and destroyed the car it was in. We're still looking for the flywheel and clutch...it's somewhere in his garage amidst a mountain of SVX and turbo Grand Am parts and pieces.

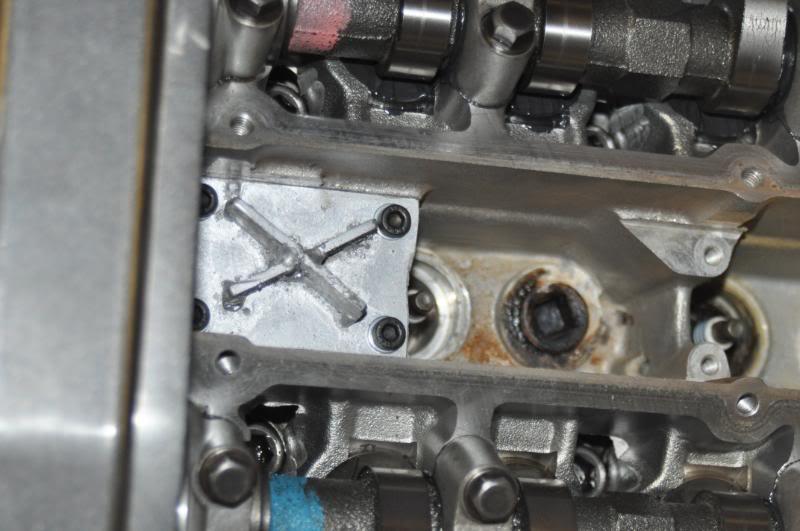

I popped the pan off of the CA. I wanted to reseal the pan, but also wanted to check the condition of things in the case. Turns out everything looks new. I really do think the Bluebird this engine was installed in either was in a wreck very early in the cars life, or the engine was replaced and the car was soon junked. All the sensors, accessory equipment, etc are all practically new.

DET Pan

DE Pan

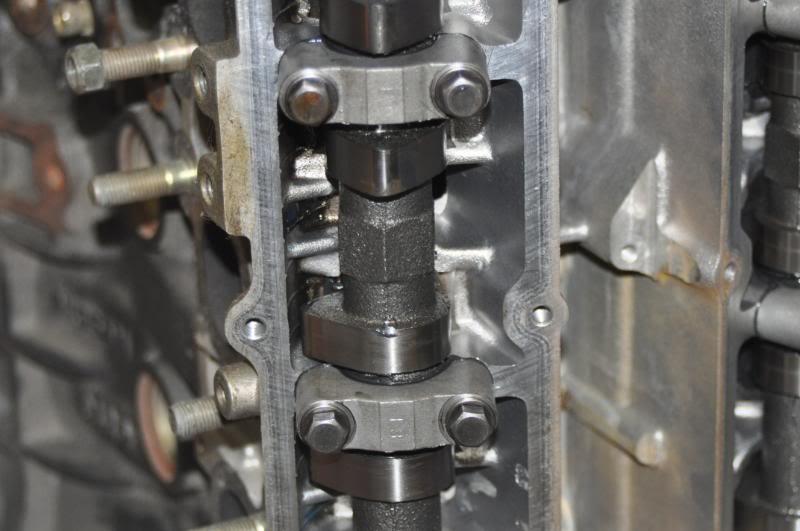

DET Girdle

Should be ready for the 8,000 RPM range. Assuming the rods hold out.

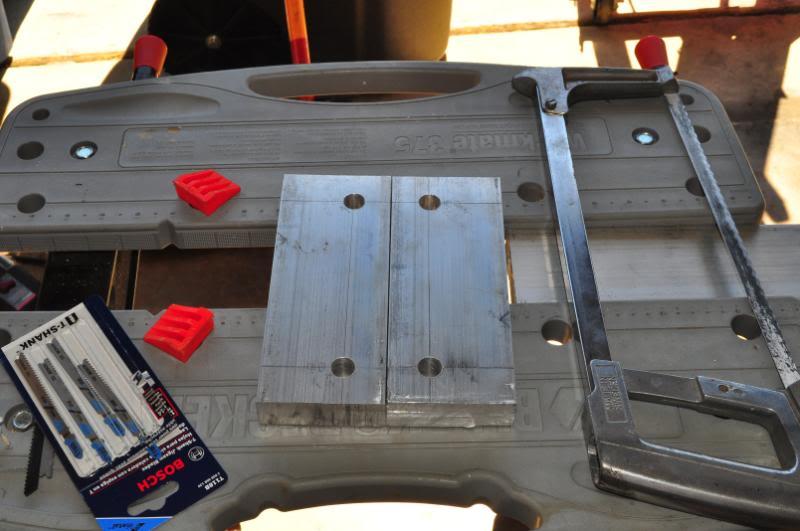

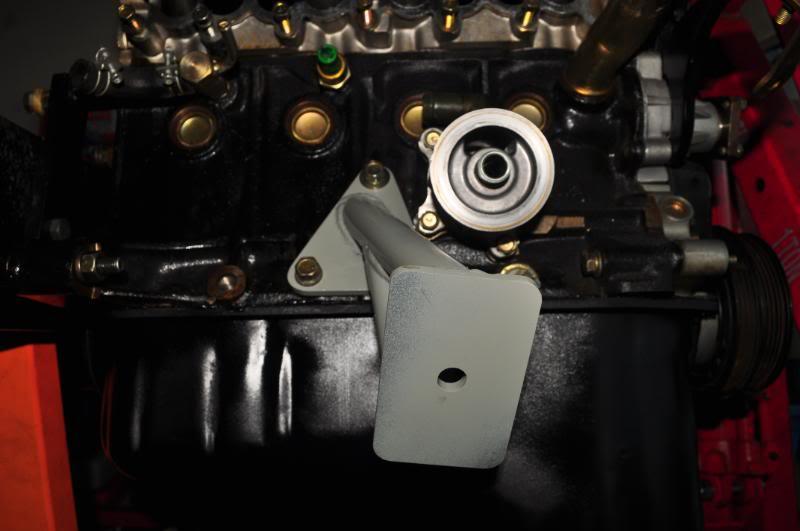

Crank girdle is installed and torqued down using stock main bolts:

The counter weights look immaculate:

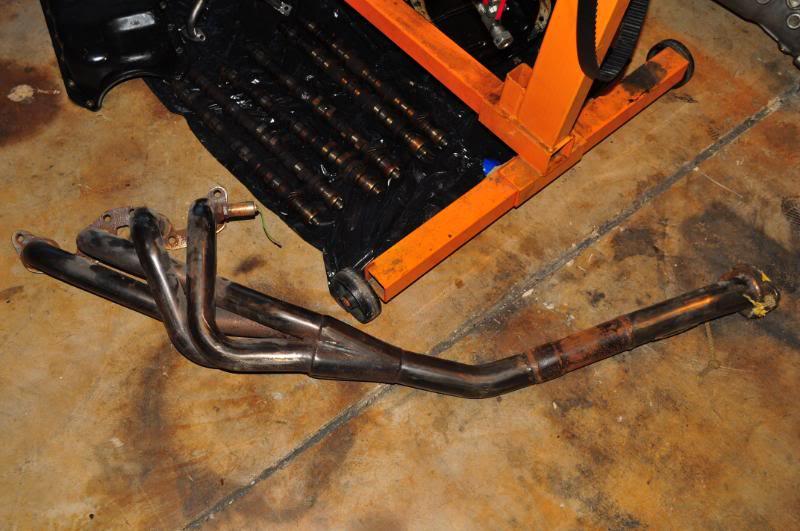

The RS*R CA18 RWD header:

I started cleaning up the DET oil pan. I got most of the grime off and did an initial sand. The primer was primarily to halt flash rusting. I'll see how it comes out and if it's clean enough I may just prep and do some final coats. The only issue remaining is the oil return line. I need to weld a plug over it to cap it off to use with the DE:

I also got my 7" Grade 8 bolts in for the subframe and now have it firmly in place. The only thing definitely missing from the front suspension is the sway bar. After I get the clutch and have the engine installed I'll pick up a sway bar and get the front end completely finished.

Started putting some finish coats on the oil pan. I decided to keep the oil drain unplugged and use it as a oil drain for a catch can...if I go closed circuit.

I also modified the oil pickup to work with the crank girdle.

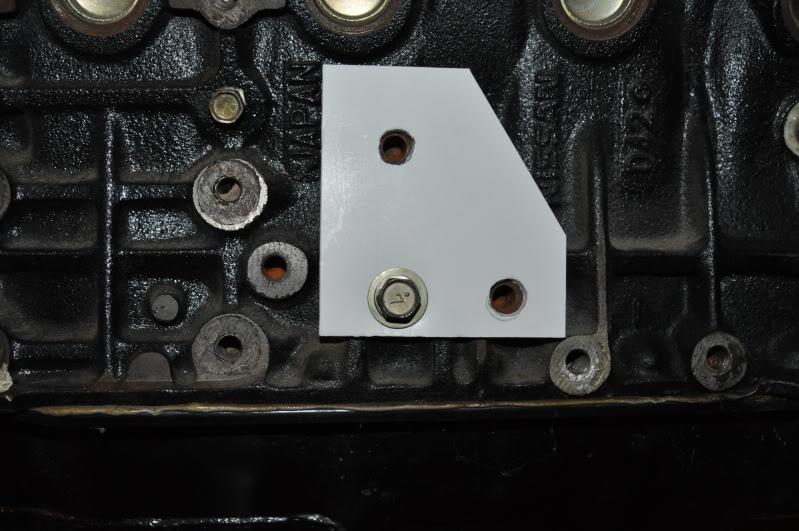

You can see how the DE oil pickup is mounted to two points on the pan mounting face.

With the girdle there is only a single mount. The DE mounting points are inaccessible with the girdle:

Once I get the inner portion of the pan cleaned up and finish painting it I'll get the pan installed (Saturday at the latest). My engine/trans mounts should be here by Friday/Saturday (with any luck).

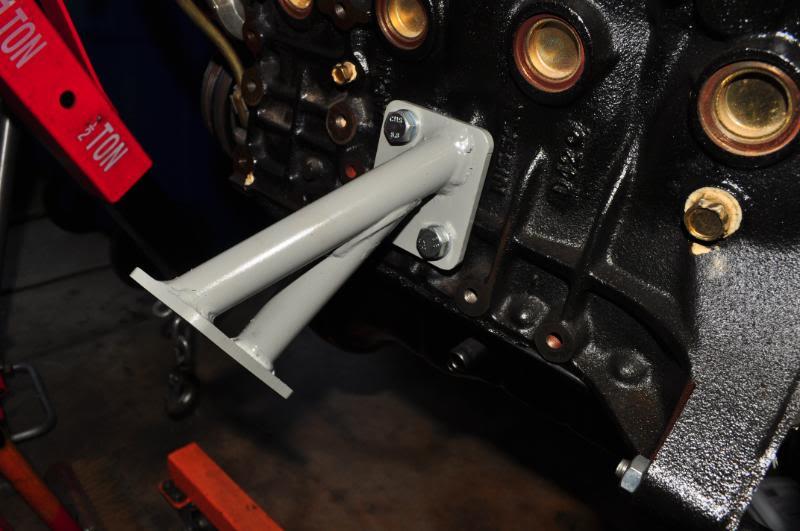

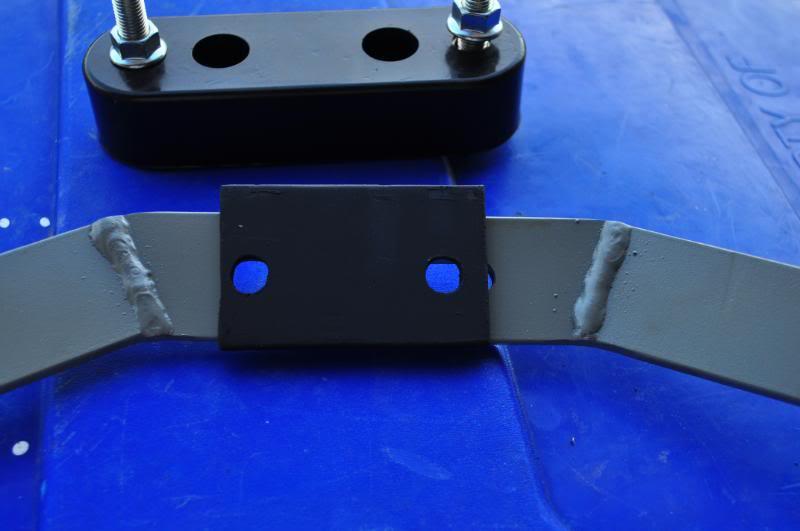

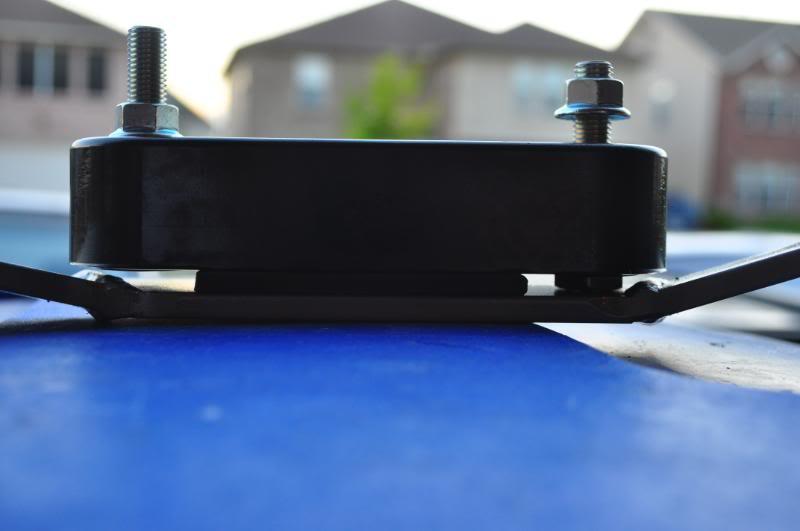

Got the engine/trans mounts from Flipside Customs. Things look very good so far. I only have an issue with the trans mount. It was designed around the stock or Nismo mount bushing. I'm using a Peak Performance piece and it is a bit wider.

Started getting the radiator support ready to be a bolt on/off affair:

Here you can see the space between the trans bushing and the mount bracket. The bushing actually rests on the brackets welds:

Started to clean the inside of the trans. It was opened in the junkyard when I was swapping bellhousings out and I just wanted to clean things up and get the dirt/rocks that may have stuck to the gear lube out:

I decided to use the clutch that was on the engine when we got it. It has low miles on it. The only reason being that I'm going to break in the rear diff, so I'd rather use a junk clutch while the rear diff is breaking in. Once I run the engine and rear diff for a while I'll upgrade the clutch and flywheel.

Once I get the trans cleaned the only thing I'll need is a set of flywheel bolts and a snap ring for the trans main drive gear bearing. I'm going to try to pick up some flywheel bolts today. The snap ring will have to wait until I get the bellhousing and everything bolted back together b/c I have to measure the snap ring valley after the bellhousing is torqued down.

I was able to get the engine and transmission completely bolted in on Saturday. It's in there solidly. It doesn't move a bit even when applying a lot of pressure.

I ended up with a couple inches of clearance between the pan and the cross-member.

Nice build and details!

Posted by Diggymart on 12/12/20 @ 10:25:55 PM