You must be logged in to rate content!

191 minute(s) of a 391 minute read

12-28-2020

DarkLighter Tuning Kamei Wabbit build!

Compliments of T3Bunny @ VWVortex.com

January 08, 2009

Well people I am finally building her! I have threatened to build another Bunny for years. Its tons of fun putting together cars for friends, enemies, customers and everyone else in between, but my own projects have suffered from lack of attention.

After helping Patatron out several years back while he built his tan bagged bunny, I knew what I was looking for for my next project. I wanted an older German built golf between '75-80.

Since at that time I lived on the East Coast, it kept getting put on the back burner. Your simply not going to find one of these cars out there. Heck finding a rabbit of any vintage in even okay shape is expensive. Fortunately a move out to Utah made this dream finally become a reality.

Last summer I finally got the call I had been waiting for. "I know where theres a clean '77 in need of rescuing." When I got there I found this gem.

I LOVE the external hood latch release!

Pictures realy don't do her justice. The body on this car is in damn damn good shape. Dents and dings total out to be three of them. Two you realy have to look for and a third thats still an easy fix. My buddy gave her this stamp of approval.

We were quickly off to gather up the neccisary funds and to gas up the ford. Soon we were leaving with this!

I know that pics not the best but oh well. The ride home was actualy a little too eventfull with a broken strap causing a few moments of panic.... All is well that ends well though and we managed to get pulled over quickly enough.

She came with an interior FULL of cool and rare old parts. Some old 4 speed trannys, a 1.6L motor, old pre lambda CIS setup, a couple distributers with the dual vaccume cans and my favorite.... The dash! This was a large part of the reason I wanted one of the older rabbits to begin with.

And another cool little gem found in the car. For those not in the know, the early bunnys have metal stalks. This car actualy came with two sets. Supposedly they can be polished up nicely. Might just have to give it a try!

So it was time to start collecting parts. Wow it was a good summer too. I scored so many little goodies I can't wait to post up pictures of everything. But to do so tonight would take me hours. I litterly have a nice shed full of bits ready to go now.

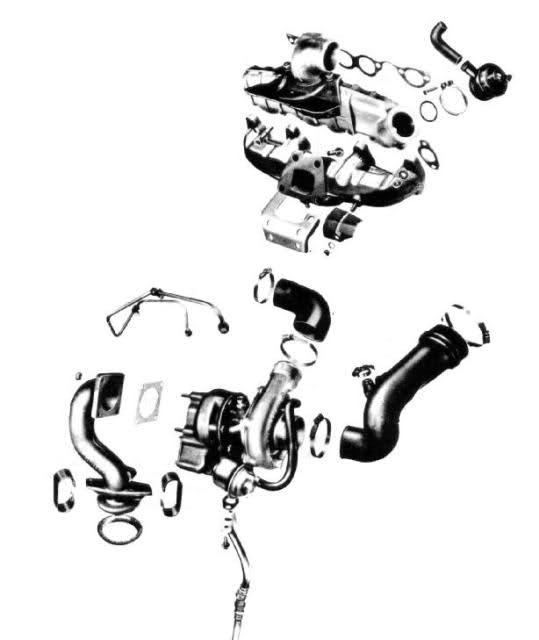

I have a very defined gameplan of how she will be built and what the final outcome is going to be. As always I will be boosting. Nothing too insane as this will be my daily driver. So heres the setup going on her.

Nothing insane, but OE and RELIABLE. After living with my turbo cabby for over 4yrs... those who know the stories will laugh and understand why I fell in love with a turbo setup stamped with vw part numbers...

Monor issue discovered though is this does not bolt onto a counterflow gaser head. It interfears with the intake manifold. Oh well. I already have a solution to tackle this anyways in the works.

Mmmmm so so much to do. Problem is where to start? Well first off I needed to clean out and inventory what was inside her.

Cleanup reveals suprisingly decent floors. Theres lots and lots of rust. But poking and proding reveals its all just SURFACE rust!

Unfortunatly my generous nature had bit me. When I went to get my pressure washer out, I discovered one of my freinds had apparently broken it. So cleaning the interior out further to get a closer look at the floors has been put off for now. I am hoping I didn't put it ff for too long though as now winter has set in and I have a nasty greasy and icy mess.

Well it was time to do some more cleaning. Ed was bored and decided to remove some brackets in the engine bay. Fortunatly the PO had been kind enough to hand us the car with the engine mounted here....

So it was realy easy to get into the engine bay and start cleaning!

I am realy tempted to run this little GEM. But I have other plans for it and ts unlikely to end up in this Bunny. Still.... Tempting.

I didn't get much more done until winter set in and I decided to tackle the suspension so I could move her. This stance was just too much...

Attacking the front....

I know "pics or it didn't happen" but hey I had so much fun I forgot to take pictures of the H&R coilovers after I put them on. But I did snag some after shots.

I know she needs to be lower. Have no fear there we will be going a LOT lower. In fact in this last picture only the front has the coilovers on. I still have some tricks to pull out for the rear axle and I realy am not sure what one I will even run as of the moment.

Lemme toss this out there. I am going as low as I can with regular H&R coilovers. When I swapped the front suspension out I put front a-arms on it and brackets for an OE swaybar. I am exactly reproducing the suspension I ran on my cabby for YEARS and loved it. My thought is to swap in the rear setup also.

I wanted to change up for ultra low H&R's but decided to body drop it some instead if I need to. I think I can still get away with running the swaybars as I am realy more interested in handling than in the end getting it another half inch closer to the ground. Handling has to come first.

I dought I will change my mind on the swaybars, but I am willing to listen to experianced opinions on this as I have seen some people saying that they are actualy a bad idea...

Well I got lots more goodies to post up shortly! Stay tuned for more pictures!

It actually came with that badge! I pulled the others off for the time being. Might keep that one, but probably not. To badge or not to badge is one of the few questions I am not really decided on.

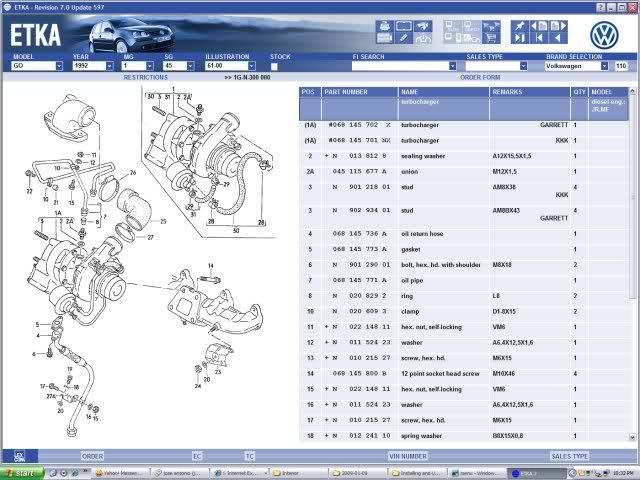

Mmm I am not sure on the turbo actually... I don't know much about it other than its "supposedly" off a MK2 TD and I know its not a T3. The Mad Scientist looked it up on his fresh ETKA install last night and proclaimed it to be a K24 turbo. I have been wondering about that wastegate setup myself.

A quick search only finds this picture...

Doesn't tell much but the angle of the wastegate actuator is a lot different from the VNT setup. I would like to know more about this particular turbo though.

January 09, 2009

I will fix the problem by never having a counterflow clearance issue to begin with. No flipping or clearancing will be required.

I want this engin bay clean and bare. Theres not goign to be intercooler piping going everywhere, or anywhere actualy.

I have a few tricks up my sleeve to pull this off.

So I have gotten a couple IM's and emails about the turbo setup. I never intended to run the TD setup on a counterflow. I actually got it in trade for a new SPA manifold I had because it didn't fit on the counterflow.

It is possible to it this on a counterflow, but not easy. It requires flipping it over then a CRAPLOAD of clearancing of both the flanges for the exhaust and intake manifolds. Then the reinforcing ribs on the bottom (now top) of the exhaust manifold need to be cut off.

After doing this it changes the location of the turbo outlet to the undesirable passenger side. Its a pain to clearance the DP over here. Oh and the turbo now needs to be reclocked. No big deal here. But the final kick in the pants for me was the fact that flipping the turbo and manifold makes the OE bracing brackets useless.

I had a lot of downpipe reliability issues with my cabby setup and I really wanted a complete OE setup.

Another possibility on a counterflow would be to reuse the diesel intake manifold and simply relocate the throttle body to a different location. On my setup though I am trying to eliminate all extra piping and plumbing not absolutely needed. A remote TB would be awesome though and if I used that I would retain the OE diesel blowoff valve on the manifold and add a second one between the TB and intercooler. Would give a killer dual/sequential BOV hit!!!

Mmmm okay I am not sure what type of turbo this is but its not a T3. Or not a standard one anyways. The bolt pattern is wrong. I have always understood that "t3" primarly refers to the bolt pattern and the basic spool cartridge type. As for the cartridge though I am thinking a T3 one would interchange with the K24. For now I am going to go with the assumption that this is a K24.

Lets pull up the ETKA information on this and see what it says.

That doesn't tell us much. Anyway simply adding a t3 weld on flange to space this out isn't going to do the trick. When I get a chance I will take some side by side shots with a T3 for comparison.

January 12, 2009

Yeah I think its a K24 also. Not sure nor am I really too concerned about it. I think I might be able to use a T3 spool in the middle. When I get around to fiddling with that I will take some pictures and toss out some more updates.

Speaking of updates, this weekend was very productive! The plan was to tear into the floors and see how bad the damage was. Need to prep it for blasting in the next week or so and see if we are going to need to weld in any patches. Here was our starting point. Can't really see how messy the floors are here though.

After chipping a crapload of ice out of it.

The worst is the passenger side. Behind the seat area there was about two inches of standing water that had frozen hard. I was REALLY concerned about this area. But when we brought the car home one of the 4-speed trannys puked all its gear oil out. Turns out the gear oil probably prevented any damage from happening. It took a LOT to get it even this clean though....

I stuffed a heater into the car to get everything nice and warm. Hopefully that will help with getting this oil cleaned up the rest of the way. Once I get all the oil up, I will tackle the sound deadening on this side. Cooking gear oil STINKS. The sound deadening is bad enough as is.

So the worst of the rusty areas on the car is the foot well on the passenger side. Pictures really don't show this well but its not anywhere near as bad as I would have thought. So far it seems its all very minor surface rust. Just lots of it. Soon as I scrape it and get the rust off its actually smooth and not even pitted.

Onto the drivers side. It was pretty clean over here. Still had to drill a drain hole to let water out. But mainly it was just cleaning up the mess here. The scary part is actually going to be the OE wiring clean up. Theres a random circuit board and a rheostat attacked to the steering column that I am completely lost a to what its function could possibly have been. No matter as I am dumping ALL the OE wiring from tis in the garbage. Updating it with the harness I pulled out of the 83 unless I manage to score an inexpensive CE2 cabby harness.

Anyways the damages, or lack thereof.

The back of the car cleaned up very nicely. Only a few areas with very minor surface rust. Still have some random leaves and stuff back here we will ave to get rid of after blasting. We will have to give the whole car a super thorough cleaning then anyways.

The dash area looks even more amazing! I am betting the windshield on this car has never leaked. All the areas where I usually see rust damage are spotless.

Since I am working outside and don't have a MUCH NEEDED garage I needed to tackle the area where much of the water was getting in the car. Where the heater box goes. Cleaned it up and taped it off. Nothing fancy for now, but this will defiantly slow the ingress.

As soon as its blasted the heater goes back in and this should solve the rest of it.

A question though. On the newer rabbits I have always seen a drain tube off the bottom of the heater box. Granted most of these cars have AC, so its pretty much a necessity. I am wondering though if putting a drain tube on the bottom of this is a good idea though? I guess the rain tray plastic cover SHOULD keep the water out of there, but I am not counting on it. Any thoughts here?

The engine bay has been cleaned up and most of the unnecessary brackets removed. I still have a few more to pull out. Trying to decide where to put the washer reservoir... I really don't want it in the engine bay, but relocating it to the back of the car is silly too. So far I have left that bracket in place. I will need to run another reservoir The bracket on the drivers strut tower is perfect for the adjustable fuel pressure regulator so it will stay unless I end up using an OE FPR in the rail. I really like having an adjustable one though.

So far I am very happy with the progress we are making. Most of the engine bits are done and ready to go. Just need to paint the motor and tranny and start bolting it all together.

One of my best freinds is a body and restoration guy. He gets tons of practice as his father builds enlish cars. Hes picking up the car sometime in the next week and doing it. Not sure what media he is going to use. I think he said garnet.

Once its blasted the floors are being done in Por-15. Less critical CLEAN areas will be hit with Vari-Prime primer and then painted. ANy non critical areas that still have a little rust will be hit with Rustoleum and then painted. The plan is to not have ANY rust left on the car.... But still going to need to keep time and material costs down and "the plan" usally never goes accordingly.

Price? I am giving him a Toughbook in exchange for materials and labor. Cash rarely changes hands. So far for this project I am only into it the cost of the shell and a single can of clear engine paint.

January 13, 2009

GODS I hate the smell of gear oil in the morning. Or any damn time for that matter. I think ALL that stink was the burned gear oil that had soaked into the floor on the passenger side. Cleaned up most of it but its still soaked into the sound deadening in that area. Thats coming off in the next day or so though...

FalconFixer and I rolled out to the JY today and came away with some good stuff. I only had time to get about half of my shopping list, but everything on it was there.

Got the first part of my braking system, a 22mm master cylinder off a Passat. Scored an A3 wiper motor assembly easily enough to upgrade my crappy stock A1 setup. And found a cool plate hidden in a rain tray.

Theres pretty much nothing reusable for brakes on this car. I am hoping the lines themselves are okay, but not even betting on that one. This car doesn't even have power brakes... I will be grabbing a booster tomorrow since I have to get a steering column bracket anyways.

Since I needed to inventory my brake parts and see what else I needed, I went and dug into my hidden stash. I found some goodies!

Turns out I already have a full rocco 10.1 setup other than pads and discs. Found a 5-speed shift linkage set and all new bushings for it (not shown). Found my clear blue EMPI dizzy cap. One of the first 16v prototype crank sensor setups from 034efi. Most of the turbo plumbing bits needed including a special metric adapter turns out I will need for the top oil feed. New waterpump. Dipstick tube and wateroutlet also new. A crapload of gaskets and I think all new engine mounts.

And these goodies got all cleaned up today.

We have a REALY nice Centerforce Dual Friction clutch setup thats served me well so far. An Autosport Turbo cam and a stock flywheel that I will probably exchange for a lightened one. Well I am off to bed as I have a VERY long day ahead of me tomorrow. Have to make another JY run and then bust ass cleaning and getting the car ready for blasting.

January 14, 2009

Like if I don't put my cars back together soon I will run out of places to put everything. Many a conversation has begun with somebody going "Damn I need x rare part." and me going "Fug now where did I stash that?" I need a metal detector lol to keep parts from vanishing. Today somebody thought they would be funny and hide one of my race pack clutches...

Last summer I lent somebody my GTI flairs to testfit them. A perfect set. I can't for the life of me figure out who I lent them too and they not come back home yet.

Oh well.

Oh yeah so check out them calipers! Lightweight aluminum MK4 and they bolt right on. Sexxy as hell too! I didn't get much done today other than grabbing those, a pedal assembly (the 77 doesn't have a brake switch on its pedal assembly), and a cabriolet booster compleat with master cylinder and proportioning valves. I took a few minutes to clean the calipers. They are cleaning up nicely. Oh also -=cough=- found a bunch of random bolts in my toolbox that I proceeded to clean up and stick on top my heater for drying out. Was missing some stupid parts like ball joint cinch bolts and the like.

Tomorrow will be a very busy day though! If all goes according to plan, the Dub Cartel will be picking up two cabriolets. One might be rebuilt. But the other is being cut up for parts. And before anyone asks NO you can't have the fenders and core.... They are already called for on the next 5-6 cars they have a talking too.

January 15, 2009

My parts stash is top secret and under heavy guard! Besides it would probally take days to photograph it all....

Wheels and interior are going to be two realy cool treats I have for the car. My wheels are already sitting here. They are still brand new in their boxes too!

As for progress over this weekend, unlikely to do much if anything to the Bunny. Theres a few projects that need my attention and I am suddenly in dire need of a second car. The infamous cabby is in sad sad shape right now.

Shes missing a few small parts....

So a bunch of the guys are promising to stop by and looks like we will be making an impromptu party out of the ordeal. As of the moment I think we will be putting a 1.8L 16v into her. I am just trying to scrape up a few odds and ends parts to make it happen. I am torn though between that and a 1.6L 8v. I have enough 1.6L's around that I have no issues with seeing how hard and high I can spin one. If it blows up its a short ordeal to drop another in. If I had a second turbo setup for an 8v, I would do the 1.6L and boost it.

Shes been sitting a while and the interior needs some attention too. But fortunately its dry and nothing serious.

Engine, tranny, and MegaSquirt in one day! Should be entertaining, So anyways I will stop hijacking my own thread. Maybe I will post up a short build thread on that car.

January 16, 2009

It is an Etienne Aigner Edition Cabby! I love the interior. REALLY want to put it in a rabbit. But its too much a piece of history to do that. Its bad enough that my plans for the cabby will take it in a different direction. Nothing major but the damaged clipper kit is coming off and shes getting the chrome bumpers from the '77 flushed.

I have been torn on the cabby. Tried to sell her a bunch of times but could never get an amount that would let me sleep well. Heck I paid $2500 for her 5yrs ago with a blown motor and dying automatic. Then I turned around and immediately dropped the same right back into her to get her on the road.

Anyways shes been a damn good car and is getting put back together for the missus to eventualy drive. Maybe I can finally get the keys to my Audi back long enough to send it to my fabricator and finally get its fuel rail made and turbo installed...

Well not to steal the thunder from the bunny as this is her thread and shes a jealous little thing... So I have the coolest VW friends anyone could ask for! Last night I hear a knock at the door and my buddy FalconFixer walks in bearing gifts. Not sure what I will do with this first batch, but it never hurts to have spares and options! Theres a few things I wanted to try too, but not on my only grill!!! Now I can play.

As cool as those are though, that wasn't the real suprise. He had hinted to the surprise a few days prior in a side comment "I have a windshield banner you have to put on your car!" I was all "Mmm okay." and thinking internally "Why would I ever run a windshield banner?" So I just let it slip from my mind until he handed these to me last night!!!

As some of you know, I used to live out on the East Coast. For a long period of that time I lived in Northern Virginia. Home of Electrodyne / Racing Dynamics. Well in the fall FalconFixer had found himself on some sort of top secret mission in an undisclosed location on the East Coast and wanted an adventure. He calls me up and I suggjested he check them out. So he drives a few hours to their location, just to find out they are closed for a holiday. Luckily there was still somebody there in the warehouse and they let him in to look around and score some goodies! I can't say enough good things about this company. They are truly run by enthusiasts that really love their jobs. And their customer service is out of this world. I have spent thousands with them.

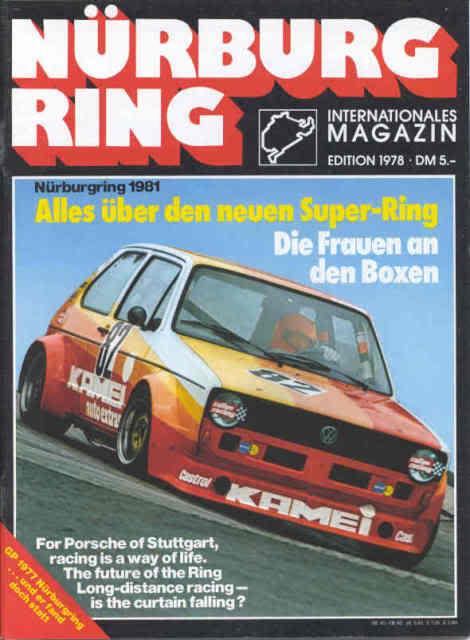

Anyways they are the sole authorized importer for Kamei products in the USA. Anyone getting Kamei goodies, they come through Electrodyne. I have found some SUPER cool and rare stuff sitting on their shelves in the past, and this adventure was no exception.

In fact a discovery at Electrodyne started this whole idea for a project about 7yrs ago. I found this sticker and just thought it was the coolest ever. Its kinda been a good luck charm and has been moved to about 4 different tuning laptops since I got it. A little worse for wear but awesome none the less.

Anyways it was a while before I stumbled across some pictures online and discovered some of the history behind the car depicted on the sticker.

Needless to say I started looking for the parts I would need to build said car. I have since found sources for everything including a full repo of the Kamei bodykit. This was the direction I was going with the car. A lucky break on a set of wheels I had searched long and hard for though, has kinda changed the direction of the build ever so slightly.

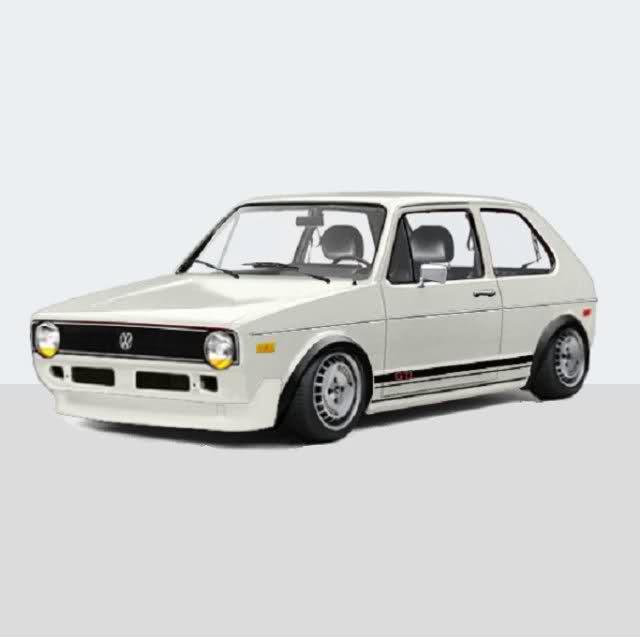

Building the full on Kamei replica is going to take some time to save up for, and honestly this particular rabbit is too clean to cut up and abuse for building the racer. I am going for a clean Old Skool Euro look for now. Playing around with Dubmodder and P-Shop gives me this.

This is really close to the final concept. We have a few more goodies going onto her. I am pretty sure FalconFixer has a Kamei hood scoop hidden in his stash.... But hes holding out on me!!! Oh well, if he does when we get to that point I am prety sure I can convince him to lend it to me long enough to make one up. If I can't find a decent original.

January 19, 2009

Que paso Antonio?!

Yeah it was time to get her (the cabby) back online. Nothing really happened this weekend though... FalconFixer and I discovered that mi Bonita had never been to the junkyard before. So it became an adventure to the junkyard instead. She had fun going through everyones junk left in the cars...

FalconFixer and I discovered that old beetles have metal signal stalks and scored 1 1/2 sets. I think we have enough colum parts to make the swap work too. It turns out I only had ONE rabbit metal set (the ones I gave FalconFixer) and the ones on my car were plastic.

We got a bunch of other goodies, but for now I am keeping them under wraps. Borrowed her parents trailer though, and finally picked up the engine for the cabby. And it came with two cans of engine paint! Seems the colors will be black and red.

Most of the rest of he weekend was spent reorganizing mi casa and labeling piles of bolts for use on both cars. SO much fun...

January 21, 2009

The cabby isn't allowed to steal the thunder away from my bunny. Wanna see it? Well come on out here and help me throw the engine in!!! The sooner she is back together the sooner I am busting out the bunny!

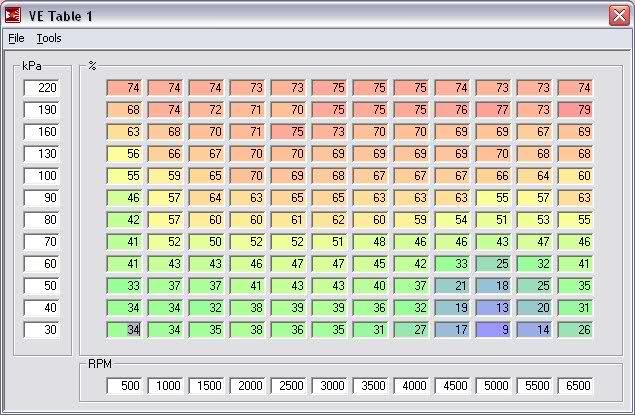

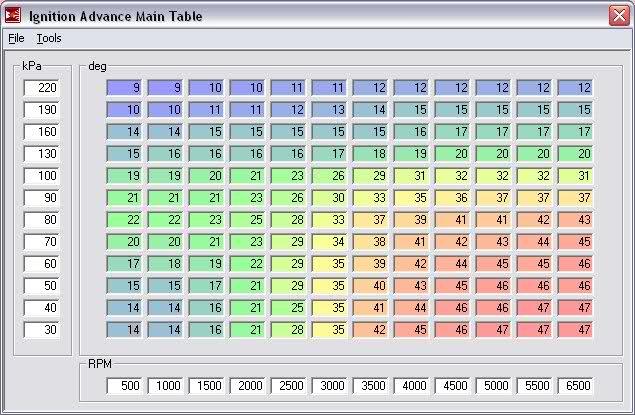

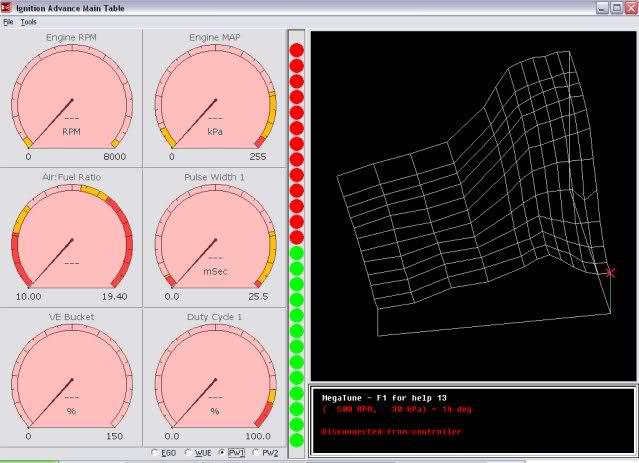

Engine plans for the bunny? I want decent fuel economy, performance, and reliability. To all the “naysayersâ€Â out there this is actually easily accomplished with the right combination of parts, engine management, and proper tuning.

The head is a modified ABA crossflow for better flow and the ability to run the OE TD setup. Its already finished and just waiting for me to pay off the bribes on it. I choose this mainly for ease of access to the turbo. Reliability goes way up with this combination too since it will eliminate heat soak caused on the counterflow, and also has the sodium filled exhaust valves from the G-60. The G-60 valves are a little beefier too with 8mm stems instead of the ABA 7mm ones.

Actually Antonio (1.8T16vhead) and I were brainstorming tonight about the bottom end. Turns out the engine that was supposed to go into my cabby over the last weekend was a bit questionable anyways. So I have it all pulled apart and found out a few more tricks and parts interchangeability that I hadn't thought about before. I LOVE 8v engines. They are near indestructible. The 16v engine on the other hand while peppier out of the box, comes with a price. Its not as reliable and once you boost it and tweak it that reliability really falls. My plan was to put a relatively unmolested 16v into the cabby. A decent combination of power and reliability but without the cost and aggravation of setting up a boosted system.

The older 8v's (pre ABA) have horrible oil breather systems... Never having built a 16v, I hadn't realized that I could simply dump the 8v PG block, and use the 16v 1.8L block instead. The 16v block will give me a MUCH BETTER oil breather setup, still has the oil squirters, and should fit the PG internals.

I really want this bunny online and running soon though. I am tempted to throw the 1.6L engine into her that was sitting in the tire well. Setup with a solid lifter head and no boost temporarily so shes drivable and doesn't need to be trailered everywhere.

February 05, 2009

Progress is slow, but very steady. Right now I have been slowly cleaning and painting all the engine bay parts. First batch is now done and the second batch is ready for painting. First batch came out really nice!

I have collected a lot more parts for the build. Braking system is complete except for a few small bits here and there. A week or so ago I got a heads up from one of my friends. Somebody was selling new VW rotors for $10 still in the box. Called up and got a little more info and cross referenced some numbers, turns out they were what I needed for my front discs!

I now have another radio choice. The plan was to run the one on the right... But I just found the black one. While the Volkswagen badged one is way cooler, the FM reception on my MP-3 player sucks. I am going to use the early '90's tacky yet BRAND NEW Pyramid EQ to jack my MP3 player into the system. The black one will go with the rest of the theme slightly better also. And it is still an OEM VW radio.

Got a few more goodies. Found the correct kneebar for the car and a spare glovebox. I wanted another box so I don't feel quite so guilty about having to cut out the back of it for the Pyramid EQ. As neat as it is, having it visible would defiantly detract from the rest of the interior concept. Obviously I will need to re-dye everything, but that was already going to have to be done anyways.

But the best I saved for last! The steering column will be pretty trick! Turns out that the 62 beetle stalks fit nicely onto the rabbit column. The trick was to use the ignition switch surround from the beetle setup. Nice because that is also metal and I can't wait to see it polished! And then there is the steering wheel, but we will leave that goodie for later...

So for the most part the progress has been in collections lol... We waited on the blasting due to bad weather and low temperatures. Need it to be warm enough within a couple days of blasting for the Por-15 to dry properly. We are about two weeks out on the blasting. By the time I get it back and painted, should be ready to drop the engine in!

February 06, 2009

No, but I WOULD for the GTI stripe setup with a red GTI in it.... MK1Autohaus sells the GTI stripe kits, but no red GTI in them. Originally the plan was to go with a full Kamei Widebody Racer setup. A lot of research finally found me a place that actually has true Kamei Widebody repo kits, not the Berg cup look alikes, but the original Kamei setup.

Unfortunately this company has some bad press in the forums and its questionable if I can actually obtain the kit from them. Cost is another big factor. To do the racer right I need three things that are all very pricey. Widebody kit. Appropriate wide wheels. And a rollcage. The wheels used on the original are BBS, no need to elaborate further there on how pricey that would be... The rollcage isn't too bad though. But dropping $500-600 on the widebody kit with no guarantee that I will get it worries me. To do the Kamei Widebody car at best would be setting me back $1500 plus paint. More like $2500-3500 though.

Anyways this build is about using the resources readily available to me that I have on hand. Looking at everything I have, I decided to go with a mixture of the early Euro GTI with a few small bits from the USA version. Especially the front spoiler. Our roads are crap here in Utah and they like sharp angles on the driveways so a duckbill was really a bad idea. I like the USA GTI spoiler anyways. And I think the bumperless look is super clean.

As for the Kamei bits? I have a small pile of goodies I am going to be using. Kamei was a name to mainly sell interior and some body accessories. They were successful because years later their widebody racers have burned a spot in our minds and we still will pay stupid amounts for old Kamei parts. With what I want to do for the interior, going full on racer is pointless anyways and wouldn't mesh well with the interior theme.

For a widebody racer I would go all out and not care about it looking a little outlandish with all the proper decals and such. With the Euro/GTI/Kamei theme I want the look to be a lot more subtle and clean.

Again I wanted to build this car inexpensively, so in the end cost was probably the biggest obstacle to building the full on Kamei Widebody. So far though we are well on track for doing this. As of now I have probally at least 75% of the needed parts. For amusement sake I went and added up my receipts. I only have one! Its $5.44 for a can of clear engine paint. As for the junkyard runs? I am always getting parts for friends and pay for mine out of those funds. Our local community is awesome too. Rarely more than a few days go by that a friend doesn't call in need of some random part. If I have it, its rare for money to change hands. It always comes back though cause its very common for friends to randomly stop by with parts I need. And most of my rare bits have been gifted to me by these same people. These were given to me a few days ago in fact!

Nine cans of white, three of red, and two black high temp engine enamel. Theres a lot more where they came from too... Easily enough to do the whole car if I wanted to. For now they are just being used in the engine bay.

Last night a friend dropped this off for me. I had almost bought this same setup from a junkyard a couple weeks back, until the counter guy told me he wanted $200 for it and a valve cover...

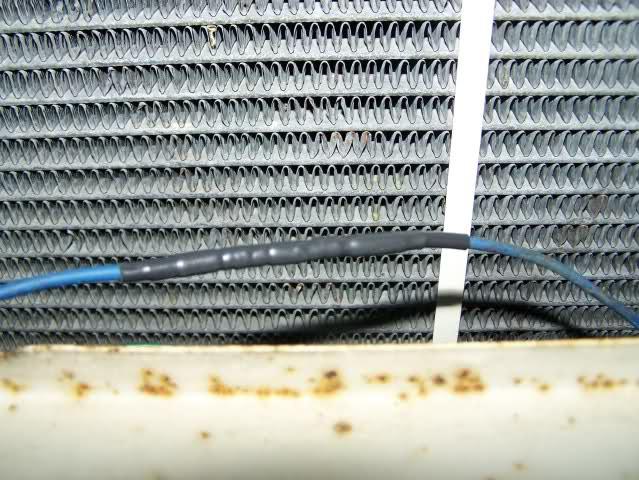

The practically brand new early radiator part is pretty obvious. Not so much is the MK2 fan setup. This price was much much cheaper. A couple weeks ago my buddy had stoped by needing a MK1 radiator setup for mocking up some insanity in his project and I happened to have it. Trading parts always works out well!

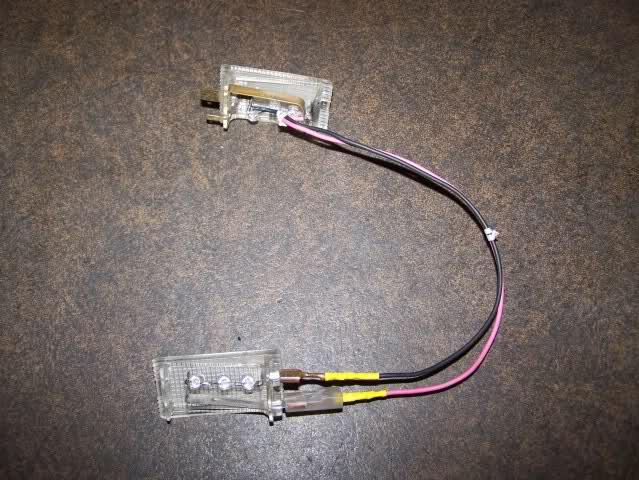

So I need to figure out how the MK2 setup originally worked. The main difference is it has a high and low fan speed. Since the car is being MegaSquirted, I will likely use the ECU to kick the high speed in. The big hurdle will be sorting out how I want it to operate in conjunction with the AC and Intercooler setup....

What can anyone tell me about how the OE MK2 fan setup originally worked?

February 23, 2009

I seriously don't think I have ever heard a second speed kick in on my Etienne Cabby... Hence I forgot that car also has that. Still have a lot of questions about HOW exactly the setup works, but I can likely decipher that with a little study of the cabriolet Bentley wiring diagrams. I am pretty sure the AC was linked into the high fan speed operation also.

Progress has been very slow. Lots going on, but nothing easily shown in pictures. Unfortunately most of the real work has been happening on the Etienne. Her engine is finally ready to go in. I have actually been using her as a testbed to work out some ideas for the Kamei. I have learned so much from living with the Etienne Turbo Cabby setup for the past 5yrs. While shes going back to a much less extreme mode, I am using what I have learned to take the Kamei bunny to a much higher state.

So by now I am sure most of us know the trick the Honda boys use for repairing and upgrading their engine mounts... If not google “homemade poly mounts and you will come up with a couple DIY's on the subject. A couple months ago I used this repair for a friends project. He grabbed a poly adhesive and while it worked, it wasn't really what we were after. It looked horrible and while functional, was not something I would want to see in my own cars.

So I decided to try again. This time I used 3M Windo Weld urethane. It came out okay but kinda messy... I was cleaning up the paint with some mild 71% rubbing alcohol and decided to try it for smoothing out the urethane also. Poured a little on the partially cured urethane and was happily surprised with the results. It did WONDERS for smoothing it all out. While it doesn't look store bought, it came out good enough to use in any of my own builds.

Yeah I know I stole one of the mounts for the bunny... I ended up snagging a few of the parts in that pile for the cabby.

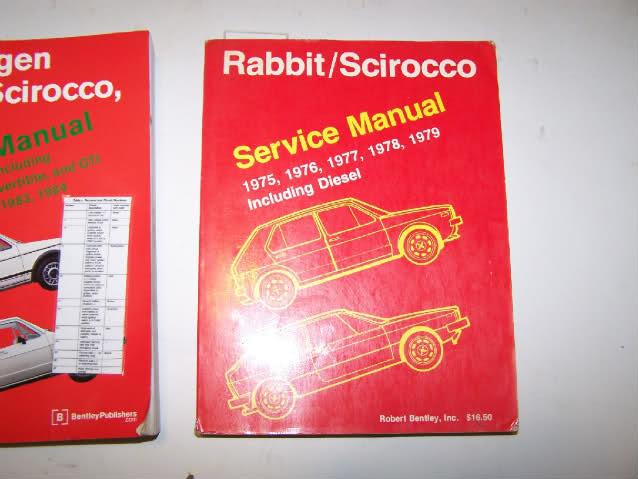

Lots of progress is happening in sorting out the electrical for the Kamei. I managed to score the early rabbit Bentley on E-Bay. Shipped for $15!

It has the fold out wiring diagrams in COLOR and is a way cool find. While the plan is to rewire the car from the ground up, likely using an '83 westmoreland harness, I still need to decipher the early instrument cluster wiring. I have a couple directions I can go with the instrument cluster setup, including a proper OE setup complete with tachometer.

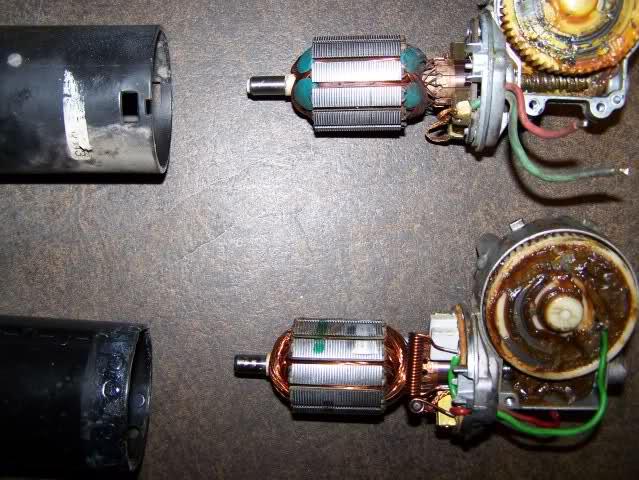

Speaking of instrument clusters and speedometers, I have learned some new tricks in this department. In the past I have repaired many (read ALL of my cars..) speedometers with broken odometers. There was a lot not addressed in the write ups I have seen here on the tex though and so I decided to take some videos of the process. I had some questions I attempted to find answers for here, but couldn't come up with anything so I decided to tear into my pile of speedometers and see for myself. The biggest question I had was in regards to calibrating the speedo on reassembly.

The only references I had seen were to lift the needle over the stop peg before disassembly and to note where it rested. Well if anyone has taken enough of these apart to notice, the VDO ones (not sure about any other brands installed) actually have a couple tick marks along the bottom. I suspected that the one between 8-6 o'clock was the OE calibration point. Turns out I was right. But even more interesting... On closer examination I discovered something very very interesting. At the very least on the 85mph, 100mph and 120mph speedometers the spring assembly is the same. The difference is ONLY where the needle sits un-tensioned. So to make an early 85mph speedometer a 120mph speedo only requires swapping the face and pre-tensioning the needle correctly. This opens up a whole new interesting world of speedometer swaps. Custom gauge faces are nothing new, but until now I have never realized that most if not all of the speedometer assemblies BEHIND the faces were the same.

I really want to sort out a VSS setup in the back of one of these early speedometers. In the later cars these were available for cruise control. I am interested in using them for a different application.... I may have to resort to a homemade output flange VSS setup, but the back of the speedometer is so much cleaner.

As soon as I have some more time, I will post up the speedometer repair videos for anyone interested.

March 19, 2009

So I have been slacking horribly about posting up pictures, but we have LOTS of progress happening on the car. I have been slowed down somewhat by the cabby, but shes basically done now other than hooking everything up and some small parts needed.

We finished prep for sandblasting yesterday. I am absolutly AMAZED at the condition of this car. So far only ONE small rust pinhole to be found on it. Everythign has cleaned up so so much better than I could have hoped for. The only depressing part is the tar covering up every bit of rust and the damn glue everywhere.

The dash area has cleaned up pretty nicely. Only real issue in there is the steering column bracketry. I really want one out of a cabriolet with cruise control as I need a brake and clutch bracket switch. I snagged one fron the JU but it wa missing the clutch switch bracket and turns out it was also missing the clutch cable bracket. Time for some welding it seems...

The biggest suprise so far is the floorpans. I knew they were pretty decent, but damn for a 77 they are MINT. The worst area was the passenger side and its cleaned up really really nicely.

We are ready to sandblast FINALLY!

March 20, 2009

So yesterday there were a couple VAG's in the driveway....

It was an eventful day that ended with my Audi deciding it hated its master cylinder. It was mad apparently at all the time we spent on the Bunny.

So after a lot of this:

We ended up with a lot of this:

There's sand everywhere.

The floors looked horrible but they cleaned up super nicely. The pictures don't show a lot as the clean up process has barely begun, but you guys can probably get the idea. I was afraid the floors were going to be the one place that got us on this project. Nope. They are really solid and we only found a couple small pinholes here and there. We suspect they occurred during the scraping/blasting process.

Only found one actual rust through hole up in the raintray. Its covered by the piece of cardboard in this picture. We are thinking of welding in the patch in such a way we can use this area to drop the engine management harness inside.

I finally got the rest of the OE wiring out f the car. Theres a lot of decisions to make about exactly what goes back into it, and how. I don't have a lot of room in here since I am planning on keeping the interior clean and minimal. So its possible I will be mounting the MegaSquirt in the raintray. I am a little hesitant on this idea as obviously it will need a waterproof case. I can mount in an OE VW case easily enough, but its a pain and limits future internal mods.

Anyways more thought on the whole electrical system revamping is defiantly required. By the time I am done I may not even be running a fusebox.

The other side of the raintray was pretty clean. Just scraped and blasted and all is well. When I got the car sadly one of the parts I really wanted and needed was missing. The early strut tops. I blow out a set of the later ones about every 6-8 months. The early tops had been taken off the car and resold before I got my hands on her. So either I am going to need to find another set to rebuild, something I haven't had much success in yet, or I will figure out a way to get a set of the Bonrath reproductions into the states.

Engine bay was really clean to begin with so again only minimal work was required here.

At the moment my biggest decision to make in the engine bay is what holes to fill in, and what steering rack to run. It seems the quiafe quick ratio internals fit inside the early style rack. But to do so means pulling both racks apart and trying to find some new seals. Since these never really go bad, thats likely to be a tall order. The easier course of action is updating the mounts so I can just bolt the later rack right in.

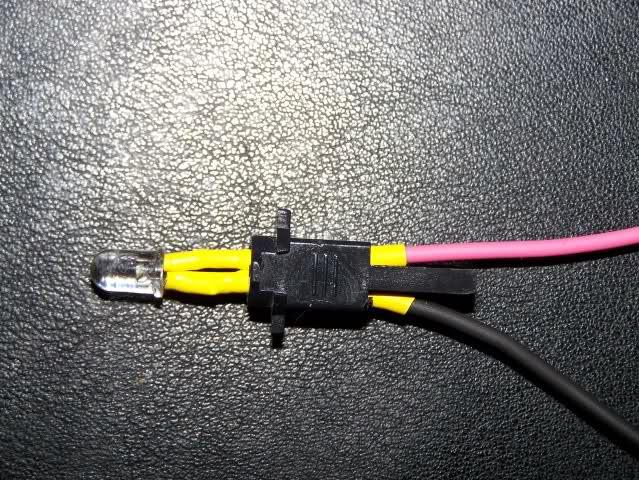

We have some more fun things going on. I have been working on a lot of little items for the interior while waiting for the weather to clean up enough for blasting and painting. In my winter junkyard adventures I found this little gem:

I am after the check engine light. I mean what VW can claim to be tuned if this light isn't on? But since I will never run any OBD system, I am thinking I will actually have to find some useful purposes for this light...

Heck yeah! I love the "base modle" ness of this car. Not that there was much left by the time I got it to tell it was a base modle.... The only clues were the single gauge pod cluster, the hoodlatch on the front, lack of swaybars (but not sure ANY of the bunnies back then had them), and a few other minor detailes. This car had no intermitant on the wiper. No rear wiper. Oh and the coolest is the blanked out glovebox lock!

The first thing I had to do when bulding this was to get rid of the single pod cluster. I am almost done with the first stage of rebuildign the dual pod I got. I will post up some pictures shortly.

March 21, 2009

Thanks Jeremy! Hey I wanna give a shout out to this guy for being a damn good seller and person. Other than stealing some early strut tops off my poor car... And then posting the pictures to prove he had them... As for the pile of parts you still have, lemme know and I come by sometime to get them. I have had NO LUCK finding a short shifter surround so I really could use that. I have a piece to run in there that means I can't use the long one...

Lol my buddy Ed and I ended up buying BOTH cars in those pictures. The corrado is sitting in an undisclosed location. I will have a new harness in her in the next week or so...

The VW community out here kicks @$$!

Anyways so onto some more pictures I promised.

I got a really nice hook up from "My Old Roc" a few weeks ago. He had a much needed tachometer and 100mph speedo, along with a cluster surround that was in much better shape than the one I had. And he had a broken speedometer. We had a deal!

So I rebuilt his speedometer and went through mine while I was at it. I have rebuilt countless VW speedometers, but this was a nice pleasant change as these are the first early speedos I have gotten to play with. I learned some really interesting things about them in the process.

Just like the newer speedos, these gears are prone to cracking. But fortunately they are the same as the later style gears so getting replacement pars isn't hard. I happened to have a few new ones in my stockpiles.

The interesting surprise is that the early speedometers are basically identical to the later style. Okay they are in a different case with a different face, but most of the internal parts are identical. This means the parts that break are swappable. It also has me wanting to swap in a MFA setup... but thats slightly more complicated as I need to sort out how to get the VSS assembly onto the back. Its worth doing though to get the newer style speedo cable in there as well.

So here we are reassembled into the cluster.

I took videos of rebuilding the speedometers and finally got my laptop fixed so I can actual watch them... I will try and get those posted up shortly.

And here you can see how clean the woodgrain on this thing is! He even had a heater controls bezel in matching woodgrain for me. Thanks Andy!

Oh and got the check engine light installed in there. That was a HUGE pain to make up. The early plastic is super hard and rubbery at the same time. It was not easy to work with and shape/file into submission. But I finally got it to where I am happy with it and it looks like it belongs there.

And check out the fioglight switch! I wish I remembered whee I found that gem. Probably out of an old Porsche. Yeah I know the headlight switch is goofy... I had to disassemble it again and put it back together correctly. In playing with my piles of old switches I discovered that some of them actually light up like on the later style. I guess these are fairly rare though. I want a full set really badly...

I did a power up test of the cluster and I am not very happy with either the amount of backlighting, or the very small amount of adjustment range on the headlight switch. For the backlighting issue I am planning some really cool LED mods to get it a lot brighter. For the switch, I think I might modify a newer one to get a larger range of adjustment.

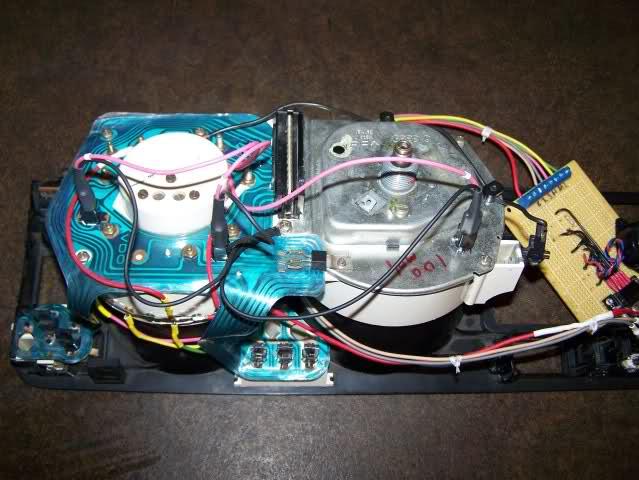

Finally I just finished building this:

Almost had to get the light box out to get a good picture of that, I am hating my camera right now. Anyways its a very versatile PIC burner. It will burn just about any type of PIC out there and apparently a pile of other processors too. Why?

Well there are a few projects in the works. First off I am building an intelligent turbo timer to get a feel for working with PICs. Then comes the fun application. I can use the MegaSquirt as is to operate the CEL when a couple events occur, but all it will be capable of doing is turning the light on. I want a little more intelligence to it than that. A PIC can be programed to interface with the MS ADC lines to create a much more intelligant CEL.

I want it to set the light if the sensor parameters go low, or too high. I want it to blink if the IAT goes high, yet go out as soon as its cooled off. The other sensors can also be monitored and have certain conditions set the light. Codes I want to see:

1)Battery voltage too low

2)Battery voltage too high

3)Coolant -40, or too low. -40 means open circuit

4)Coolant too high, probably 230

5)Intake temperature too low, again -40 means open circuit

6)Intake temputure above 150 sets blinking until it drops. This will likely be a different color LED inside the CEL.

7)MAP reading flat lined to atmosphere pressure during running

8)AFR lean out triggered while under load, this will be hooked up to a buzzer too

9)Knock detected for more than x-seconds

I am sure I will think of a few more. The setup I envision will have a plug to access the codes. A simple switch will tell it to go into blink codes. Another will clear them out. Its a pretty ambitious little project, but something I have wanted to do for a long time. For years now I have heard this feature will be added to MS, but never seen any progress on this.

So after about 5hrs of cleaning, most of the sand is out of the car now. Got a little more to do today. We are expecting rain tomorrow, so I have to get it finished and tarped up. Maybe even get a little painting done and get the heaterbox back into her....

May 15, 2009

Time for an update! Progress has been slow... But there is progress. FalconFixer and I been super busy past couple weeks finishing up his truck. It should be rolling under its own power by the end of the month so we turned our attention back to the Bunny.

Got the steering colum and pedal assembly modified and back together. I needed a brake switch on th pedal to clean up the engine bay a little more, and also a second switch on the clutch pedal for flatshift setup. The pedal assembly we found earlier in the winter actualy had a broken off clutch cable holder, so I ended up using it for parts to modify the original '77 pedal assembly. And chopped up a corrado pedal cluster in my scrap pile for the clutch switch. A little cutting and then I handed the parts over to FalconFixer and he welded them up. Turned out really good!

I had thought there was a pedal assembly with a clutch switch. I swear I remeber seeing such a beast... But further investigation hasn't found one. And making one up was just a matter of chopping up another assembly or two for the bits needed.

Another issue was the steeing rack. I wanted to use my quaife quick ratio rack from my cabby in the bunny. But the newer racks don't bolt into the older cars. Installing the newer rack would involve finding a donor car to supply the passenger side mounting bracket.

But thinking about it I realized that the hard mounted early style rack probally won't make much differance over hard poly bushed later rack... Caerfull examination of the two racks brought me to the conclusion that the Quaife bits would likely fit in the earlier rack. So I pulled them apart and sure enough the parts fit! There were some minor issues, but it went together easirly enough.

So after reassembly, cleaning, and painting, the installed rack looks prety good!

The brake booster and brackets are all painted up and ready for re-install once we source a few missing bits tomorrow.

Theres a lot of other bits finished up and waiting for reinstall too. We are hoping to also have the buny online by the end of the month. And at this point we are well on the way to accomplishing that too!

May 20, 2009

The pictures immediately above are from Double0SevenGti that he took before I got my paws on he. Shes likely sitting on her tires in the pictures as he had snagged the struts and top mounts out of her.

The pictures earlier in the thread that I took, shes sitting on H&R coilovers. Or at least the front is. Back still has the OE stuff on there. I ran these coilovers on my Etienne Aigner for a few years and I SWEAR by H&R coilovers. They ride absolutely amazingly awesome! Firm but not bouncy or too harsh. But you gotta pay to play...

So theres been TONS of progress past couple days. Not really a lot to see for pictures, but here ya have it.

Interior has been "rust converted" and all sealed up then painted now. Not perfect, but doesn't really need to be either since she will be running carpet before too long anyways.

Got the blower assembly back in there. Its actually starting to look like a real interior now!

Of course I couldn't find the original screws and mounting hardware, but digging through th piles f goodies I found some nice bits to hold it together. And big surprise, had to solder a wire back onto the blower resistor. That sucked even with my nice soldering station.

The best part though was discovering that using my soldering station in the car, was painful. Damn thing has a grounded iron and well my extension cord apparently isn't quite so well grounded. I kept shocking the crap out of myself.

Got The raintray mostly repainted before I ran out of paint, again. The sections not finished though I can do with the blower covered up. Engine bay is cleaned up a lot more too.

The biggest things not in my pictures above though are the dash and wiring. The dash is one of the better ones I have come across, but it still had some damage and cracks in it. I managed to plastic weld most of them up and got it a fairly solid dash again. Still needs a lot more cosmetic work, but I am not sure how I am going to proceed quite yet.

The wiring is going to be lots of fun! I want it online FAST so for now at least I will be running the wiring harness out of an '83 rabbit I had that was in really good shape. A few things will have to be adapted over, but I really don't foresee that being too hard. I am really stoked about the instruments and the turn stalks though! Got some pretty cool tricks going on there....

Laid the several wiring harness I have out tonight and sorted through them. Its going to take a little bit of cleanup and I will be rewrapping and recovering all them. But I have enough to get it done and nicely too. Getting pretty excited here! I am hoping to actually be powering up systems in the car by Friday!

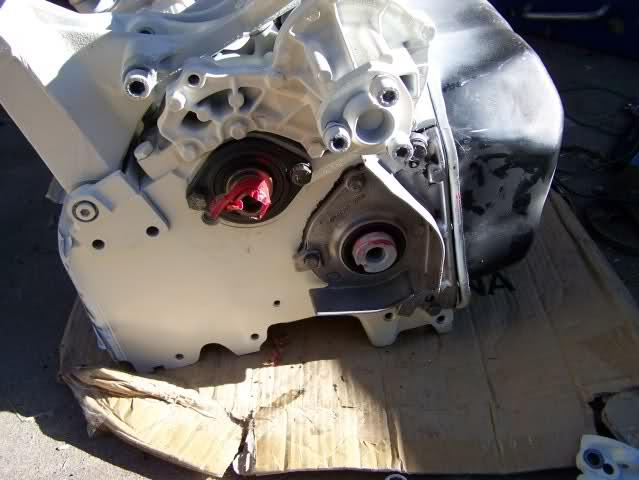

Found another picture I haven't posted up yet! Tranny is done and looking pretty sharp. I am very happy with how its all coming together here.

I keep wiping out the local Autozone's of Wimbelton White paint though...

May 21, 2009

So test fitting the wiring and trying to get the electrical systems all online today. Started with finishing up the steering column. Not a big surprise but the rabbit ignition switches fit right into the switch section on the older beetle column. So I now have a metal column surround and metal signal stalks!

The wiring for the column isn't fully sorted out yet but the contacts happen to be the same for the porsche signal stalks and the rabbit. All the contacts are labeled too, but not sure they all match up yet. Quickly going through it I only found one common wire to both.

So I went ahead and set the dash and kneebar into the car. Needed to get an idea of where the wiring needs to run.

Looks okay I guess, but I swear the dash looks bowed... Had a really hard time trying to get it to fit in there too. The holes to mount the kneebar are there, but they aren't threaded. Guess I will be using SAE hardware there as I don't have metric nut rivets.

The instrument cluster area looks really sharp. I am happy with how thats all turning out. Turns out I have a plug for the cluster so wiring that in just became a lot easier.

This little beastie looks cool so I had to pop it on and snap a picture of it.

So I was looking for the horn wire in the engine bay harness. Couldn't find it, then discovered my horns were also missing. So I went and got a set of these.

They are loud and sound way old school. They take a second to air up though... Oh well. Not like I really use my horn very often anyways. But its giving me ideas about an air tank setup....

Thanks deathhare! Means a lot and gives me hope! I wanted Fiam or hella horns, but I had $40 credit at AutoZone for purchasign too much paint... Do yours also have a small delay from hitting the button to operation?

There is a local GTG in Salt Lake next Sunday. We are planning on rolling to it with the bunny.

Impossible? Nope but its going to be a blast trying to get there. Lets see where we are...

1) None of the wiring is really sorted out yet. Engine managment is easy, I can do that in my sleep, and probally even have a premade harness sitting there ready to go. Engine bay lighting and everythign else is mostly sorted. We will be rolling with the harnesses unwrapped and raw, or maybe electrical taped together for the moment though.

2) Brakes... Rears not installed yet and fronts may be the wrong stuff. Still can put that all together in 2-3hrs at most unless I decide to paint them (I probally will paint too...).

3) No engine. The one going in isn't built yet. But I have a compleat 8valver ready to drop in donated by FalconFixer. So we will likely be running that as I don't see havign enough time to finish everything else AND have the engine built and rolling.

4) Suspension not done. Will eed to bolt on the rear coilovers. Easy enough but then theres an alignment needed. Still might need some tie rod boots too.

5) Interior nowhere near done. But we will pop the seats in and roll as long as I have instrumentation.

Hoping to have brakes done, susension, and the electrical systems powereing up tomorrow. If we finish all that we are on task for having everything online and should be ready for the show!

May 23, 2009

Well main power is finally online!

If it wern't for the fact I didn't want to spend a small fortune on wire and then the time to wire in VW's wonderously fun relays.... It would have been faster to just start all over from the beggining.

HOPING to have all critical systems fully operational today so I can start on getting an engine and tranny into her then wire the engine up.

No picture updates yet but I do have a couple things I can shoot later.

May 26, 2009

Lots and lots more progress! Other than random bits here and there and the engine wiring, the whole electrical system is online. There was a small misshap trying to diagnose weird issues caused by a damn blown radio fuse....

A lot of the un-needed wiring from the '83 is still run through the harness.I want everything online before I start pulling wiring out that I might be able to use for other things anyways.

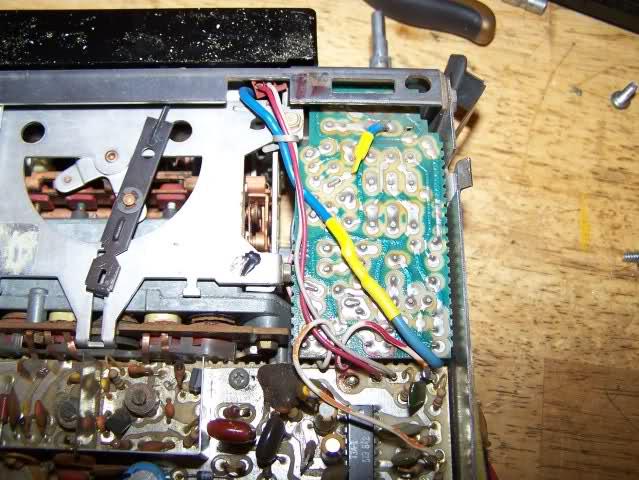

I brainstormed with my fabricator today and we solved the final engine issues. Engine is being cleaned and assembled tomorrow.

Rewiring the whole electrical system proved to be loads of fun.

Not sure if I said this anywhere... But I am using a full front to back wiring harness out of my old '83. The wiring in that car was virtually unmolested and the westy fusebox sadly is a massive upgrade from the old one. And honestly the old wiring in this beastie was a heap of junk. The '83 harness had every relay contact in it happily smeared with grease and all the relays checked out good too.

I have lost count of how many later rabbits and cabriolets I have MegaSquirted... So I am very familiar with the westy setup and I know it can easily be converted to run a MS system with VERY MINIMAL mods.

1.8T16vhead heres the information you texted me for yestereday. Sorry I didn't see your text earlier.

And for anyone else who might be able to use it, this is the pinout information for the "77 and '83 instrument clusters. It is biased towards the '77 information since thats what I needed.

'77 pin/color '83 pin/color purpose

1 Empty

2 Blue/Red 9 Green/Black Turn signal indicator

3 Blue/White 10 White High beam

4 Red 5 Red/Black Tachometer

5 Brown 7 Brown Duh, ground

6 Grey/Blue 6 Grey/Blue Dimmer controlled lights

7 Black 13 Black Switched power

8 Purple/Black 4 Purple/Black Fuel gauge

NOTE: I have seen Purple/Black as both fuel AND coolant temp gauge on some instrument clusters. On this setup they both had different colors though.

9 Blue/Yellow 18 Blue/Yellow Coolant temp gauge

10 Blue 11 Blue Voltage regulator, charging indicator

11 Blue/Black 16 Blue/Black Oil pressure

12 Black/Yellow 17 Black/Yellow Catalytic system

NOTE: Officialy this isn't wired according to the Bently, but my '83 harness had it in there still. Can't guarantee its supposed to be or where it actually goes as I just hooked it up for possible later usage...

There were some left overs in the '83 stuff not used on the '77 plug. Some are used elsewhere some not. I am mainly including these for Antonio.

3 Red Clock power

8 Grey Upshift circuit (see current track 86)

12 Grey/Green Park light indicator

14 White/Pink Seat belt relay

15 Yellow Upshift circuit (see current track 38)

I am not sure why 12 and 14 are needed in the '83 cluster, but don't have an '83 cluster around to bother caring to look into it further. Just can't think off the top of either of those actually being IN the instrument cluster. Or maybe, is there a green light that goes on when the lights are turned on? Its been so long since I have owned my '83 and '84 rabbits....

So the trick is to tackle one section at a time. I went through and got each system online one at a time in the car. Only place it bit me was the burned out radio fuse when I powered up the instrument cluster. I pulled out all the funky splices, repaired a couple broken wires, and pulled out some of the excess crap. I have also lived with these cars long enough to know the weaknesses of the rabbit electrical system and made changes where needed. Also it gives me the opportunity to change every detail of the system that I don't like. Made a LOT of subtle changes, and a few not so subtle ones.

I am leaving the harness open and uncovered for now until I have engine installed and the whole car finalized. Theres some extra stuff I will be running to the rear of the car for my water injection system, and a couple other things. Opinions wanted here... I can easily get a super clean rear hatch with rear wiper assembly, and the wiring is already there for this setup too. To run a rear wiper or not to run? I will be running a rear wiper reservoir anyways for the water injection. Not sure how I would nicely and cleanly activate the rear wiper without running the rabbit stalks. And I discovered the rabbit stalks being able to pull forward and push back screws with the programmable wiper relay. Like more times than not kicks it out when you program it. I really like the rear wiper setup, but not sure the extra weight is worth the small added convenience, or trouble wiring something up to bump it on.

May 28, 2009

Today was a good day! Changed out the rear brakes, suspension, and axle.

Got the short block painted and ready to slide in. I am probally going to be putting the motor and tranny in tomorrow minus the head. The head still needs to be reassembled and I don't have a cherry picker handy to do it all at once.

Did a bunch of other little things. Fought with the steering column again getting the steering wheel on so I could move the car aound a little. Shes moved back now ready to lift up and forward over the engine/tranny combo tomorrow morning.

I know before anyone says it "Lower it more!" I want everything in the car first before I do. And these coilovers haven't been adjusted in AGES so lowering them is going to be fun. NOT.

And I decided to stare at my wheels I had tucked into my closet. I have had these hidden away for a while now. In fact I bought them before I even had a car to put them on!

They are 15". It may be a while yet before I actually get them on the car as I still am not sure what size tires to run for the look I want. Speaking of, heres a P-Shop with them and the final concept idea.

I have several people who have promised me a GTI airdamn, but so far none in my hands yet. All the other bits I have collected and have ready to put on. Probably won't be bothering before the GTG this weekend. I mainly just want her online and running/driving.

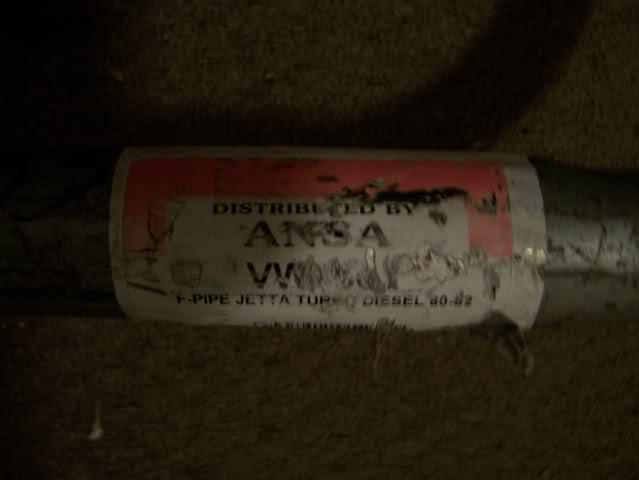

Still have to collect a few odds and ends parts. I think the only critical thing is a downpipe. Theres a few diesel bunnies in the junkyard down the way from me. Supposedly the diesel toilet bowl flows better than the gas one.

Everything is really coming together quickly! I am pretty stoked! Tomorrow I go get the registration and finish putting the engine and tranny in. Engine harness is already 90% built and ready to go. I will need to add a few things as I lay it in, but the primary section is complete.

Oh a question for you guys. Does anyone know of a source for the headlights with fogs/turns? The autoloc snake eyes just look cheap to me, and are WAY overpriced. I would pay that monie for all glass ones, but the yellow section on the autolocs just looks wrong to me. They used to make them for the old beetles, but I can't find anyone with them in stock or avalible....

Well we are getting closer to D-Day! The bunny is now legal and registered.

Have a small issue to deal with today before I can tackle putting the engine in. Stole some parts off the cabby yesterday and discovered when I went to move it back, a drum on that axle is frozen up. Couldn't even budge the car.

But I can drop the axle in 5 minutes now, except for messing with the evil brake lines from the axle to the body. Those suck. Fortunately I just need it to roll off the parking pad.

May 29, 2009

We are dead in the water. I have lost the whole day now. Got up early this morning and grabbed the head to take it over to The Mad Scientist for assembly of the valves and springs. My 8mm viton valve stem seals are missing. I had them yesterday morning and sat them on the kitchen table. Yep. She cleaned.

Nobody seems to have the right set. Even if they do, I am not sure I can recover from the lost day at this point.

On a good note, the engine and tranny are in. Not without misshap though unfortunatly. FalconFixer got into an argument with the drivers side mount and it slipped. His wrist is very unhappy now.

If anyone local has some, we are in dire need of 8mm valve stem seals, viton preferably so I only have to do it once... My valve stem pliers are also missing so pulling them out would be a pain once its all on the car.

The Mad Scientist came through for me. I have to give a shout out to him. Brent Savage over at TAS Goodyear is da man. And lemme give a shout out to the boys at Bug Craft for having a set of the 8mm seals sitting on the shelf and donating a killer EMPI sticker for the project. They are now known as BC Autoworks cause VW's marketing department sucks my.... Um never mind. And most importantly FalconFixer and the missus for putting up with my sh!t today when I was having a really bad day. Today sucked monkeyballz.

Anyways today was a comedy of errors from the beginning. Cept I wasn't laughing much. I am likely shelving the bunny for a few days. Unless a miracle happens there simply is no way the bunny can be together and running by the show on Sunday. I probably can, but at the cost and or possible risk of neither FalconFicer or I making it. We still have an ECU to setup on his baby and a little wiring to finalize here and there.

Whatever the case, I am wide awake and the missus and I are cleaning some G-60 forged pistons. I want to swap these in before I bolt the head on. If I bolt the head on before I go to sleep... there's still a good hope it can be online in the next 24hrs.

May 30, 2009

So I broke a piston oil control ring putting the nicely cleaned pistons together last nght.... The bunny is sadly shelved for the weekend at least. We need to get FalconFixer's caddy online for the GTG tomorrow than busting @$$ on a doomed bunny. I will get back to her early next week. Shes registered and I have 13 days left to get it all together and through safety and emissions.

I might post a teaser pic or two of this caddy later... If you guys are good lol!

June 02, 2009

So theres been a lot of progress over the past few days I haven't gotten pictures posted for yet. Due to not having a garage and my apartment already being overrun, I was building the engine mostly "in the car" per say. No not an ideal method, but it works and I have had to work in worse conditions. I have actually had to rebuild a bottom end while it was snowing before... That sucked. That was actually my MK2 golf though. My rabbits have only killed fuel pumps and timing belts in the snow.

I miss that car....

Well anyways not MK1 content. So heres the engine right before slotting it into place. Check out that OLD SKOOL lower crank seal cover. The timing belt shields are just the thing needed. I was sad, we were all ready to drop in one of the 1.6 litter bottom ends I have sitting here. I have one stamped 1.6 and one with just an H on it (likely a Chrysler motor). Unfortunately neither were in good enough shape to inexpensively rebuild. So I stole off them what I could.

The block is a frankenstein. Its a 16V 1.8L with 8V 1.8L internals. Heres a comparison between the 16v aux shaft and the 8v one.

Now theres a few good reasons for doing this. Mainly because I can and have the motors sitting here and the 16V was rebuilt recently... But more importantly I wanted a better breather system, and its a cleaner way around the block off plate issue on the PG block. Oh and the 16v block also has the needed oil squirters and had already been cleaned and painted. Even though I repainted it...

For simplicity and lack of garage, I set the block in resting it on a jack stand, hen slid the tranny onto it and bolted it all in. Then we had a solid "engine stand" to change out the rest of the stuff.

So here I am getting ready to set the head in with the ABA headgasket taped into location.

Freshly machined parts look so so nice! The ABA head needed to have the valve guides changed out so it can run the beefier 8mm valves from the PG head. These exhaust valves are sodium filled. Machine shop cleaned the head, cut valve seats and resurfaced it. I then hand lapped the valves and the Mad Scientist put the springs and keepers in. I finished up dropping the buckets and cam into it.

Bolting it on was easy enough. The tape trick worked pretty well to keep the headgasket centered, or at least it lets me sleep better thinking it did.

Normal M.O. on my cars is to cut down the splash guard where the oil fill cap is. I hate seeing those things when I fill with oil as they always look dirty and I can't see how clean the engine is... Retains most of the benefit and eliminates all the disadvantage of running them.

Cool, so finally onto "MegaSquirt" related goodies. When converting a MK1 over from CIS to EFI, the first thing obviously is removing all the CIS stuff. Long gone on here except for the fuel lines routed the wrong way. So the trick is to unclip the fuel lines on the drivers side and then behind the brake booster. A good yank sally pops this one. After doing that I pull the lines away from the wall far enough that I can get a pipe cutter into there. Use a good one, but keep it small.

After doing that, carefully bend them up and over to the passenger side. I tuck them behind the brake lines. Theres a clamp down there PERFECT for catching the lines. I reused one of the rubber holders from the side we pulled them off of. Now getting the clamp around it takes creativity and is always a pain to do... Sometimes I have to go in through the hole for the tie rods. Usually it takes two people, one holding the lines in place and the other finagling the clamp and pulling it over with an assortment of weapons. Pliers, prybar, screwdrivers (that of course are NEVER to be used for "prying')...

So after sorting out fuel line routing, down to the bottom of the motor to finish up a few more things. Contrary to what I have seen elsewhere online, you CAN run a windage tray gasket setup and a baffled oil pump pickup. You just have to use the right pickup! I am not sure what engine this one came out of, but I have been abusing it for a few years now. Hope it doesn't rattle as I broke off the final clip... Now it will just be held in by being pressed against the windage tray.

When I do this, I spin in 2-3 bolts to hold the tray up and out of my way so bolting the oil pump in is a little easier. Then its time to bolt in my modified 8v oil pump! Its made with a 2.0L 16v oil pump with the shaft swapped out for the 8v one. This was the trick I used a few years back for the most flow and pressure... But I think theres actually a bolt in 8v pump that would do the same. Again parts I had on hand I made do with. And here we are all bolted up!

Engine bay is really starting to look like something finally!

Not sure what if any progress will happen on this today. I got work, and some other projects, to attend to. I am hoping to have the final bits ready to be bolted to the engine though.

We didn't make it to the GTG last weekend for those who aren't local and watching this. FalconFixer's caddy is all online and ready to go, but having issues getting the COP setup to work. We have a really crappy RPM signal going into the ECU that needs to be sorted out. Unfortunatly my dialy driver Audi 90 has also developed what sounds like a rod knock at low load and rpm. The bunny pretty much has to be driving by the end of this week or I am likely to be carless...

June 03, 2009

Lol yeah I wanted to be a little different. Besides in all the installs I have done, my harnesses just disappear into the engine bay. I WANT it to pop out and be all "BAM here I am!" I like the color on the car (for now anyways) and figured that color matching most of the engine bay to the car would give me that extreme minimal look I am going for. I want the minimal look without actually smoothing the engine bay and removing anything. So far its defiantly working.

Later on I would LOVE to change the whole car to panama brown, when I get around to a perfect body restoration. But the white works and works well. The Panama Brown would detract from the old Euro GTI, turned Kamei theme I am going for.

So amazingly enough yesterday was super productive! With a few questions rapidly answered by fellow texers, I got my front brakes sorted out. I am not 100% sure what these came off of, but I think it was a scirocco 16v as they bolt right up. I do remember I got them on ebay a few years ago for under $50 shipped! Calipers and carriers. They been in storage since I really had no need for them.

Honestly though I can see why I never bothered to upgrade to the 10.1". I had crossdrilled zimmermans all the way around. These are a really minor upgrade in size when set together. The calipers look a bit meaner, and possibly even bigger. I just might see if they fit on the smaller carriers and 9.4" disc setup... Dunno yet.

So onto other details. The OE fitment turbo setup, didn't fit so well! I am probably missing the one piece needed to make it work perfectly. The OE drain tube setup. I had to tweak, cut and grind, pulling the turbo on and off 5 times for a couple hours before I got it to fit well enough. Ended up grinding a good chunk off my drain fitting flange and the back retaining bolt so it would rotate far enough to let me put the drain fitting on. Its hitting the wastegate. Overall not too bad though. I can pull the turbo off in less than 30 minutes I estimate when everything is hooked up and completed. Takes about 5 minutes now.

I need to purchase a fitting and have a line made up for the drain. Its going to be a nice straight drop with a 90 going into the pan. Simple and clean. I already have the oil feed line made up and ready to go. Actually going to be reusing the one from my turbo cabby setup. The fitting on the top of the turbo? Its a 1.8t adapter I just happened to have kicking around that I bought from ATP Turbo 3-4years ago when I turbocharged the cabby. Props out to ATP! Love those guys!

I know, not running proper exhaust nuts. Thats fine for now. The washers will do most of it. I hammered 7mm washers onto the 8mm studs. Should hold nicely until I have time and money for the proper nutz. And lemme tell you, those washers aren't coming off then!

So turbo is in and looks pretty nice sitting there. I am ready to bolt on the final bits and fit the harness. Its going to be a full harness setup as I am running all the OE engine wiring through it. I will separate out the starter, reverse lights, and power though as I have seen this section get fried before.

Anyways I am hoping to have the harness fitted today and to finish re-painting the brakes. Maybe even get as far as getting the radiator and fan shroud cleaned and painted.

Whats left? Lets see.....

1) Got to button up lots of minor suspension things. The damn OE fuel lines will have to be moved I discovered last night. They are going right through where the bracket for the front swaybar goes. And this car has larger studs holding the rear control arm bracket in. So I have to drill out the swaybar/control arm bracket holes to fit on this car. Surprised at this...

2) Need to fit in the harness and finish it. Getting the MS system online after that will only take a couple hours. But I still need to sort out and run any extras in the engine bay I need now.

3) Finish painting everythign I need to have painted that can't wait until later. IE most of the engine bay stuff going in. May wait on things like the alternator and starter for now that are quickly removable.

4) Finish installing whatever brakes setup I will be running. I need to clean the rear aluminum calipers still. Sort out rear brake lines for the lightweight calipers. Paint and install the master cylinder and reservoir, and decide if I will run a warning style brake cap or not.

5) Cooling system sorted and installed. Probally fairly easy, but I am not sure how the earlier system without the overflow tank is setup. And I am running the OE oil cooler setup for now since its simple and clean.

6) Fan wiring upgraded. I am running the MK2 fan setup to compensate for running the cleaner but not quite so efficiant earlier radiator with cap.

Once the car is online, the final stage of cleaning the OE wiring up will commence. I want everything in the engine bay integrated into the engine or main harness. No seperate harnesses running in and out. All the alarm wiring will be in the main harness. The main one will be left “raw and openâ€Â for a little while to make sure I have it all sorted out and together.

Alarm you guys ask? Hells yeah, the look on peoples faces when they hear the alarm beep on a beat to crap looking car is just way too priceless NOT to do it. Besides I integrate a few other evil tricks into my alarm systems that make my life easier. Girlfriends really shouldn't "borrow' my car... I did alarm installs for a few years and hate living without those little conveniences and amusements they add. Besides, again, I already have all the parts... Except a programable talking alarm module. I need that one.

Dude you RULE! I am sitting here having a stupid moment trying to remember what question I had to ask.... Thanks for the reminder!

So no unfortunately not. I am actually wondering about the downpipe I need to run. Making up a flange to fit right onto the turbo would be cake though. And I have a feeling that ATP Turbo either has this, or can make it quickly. I want to run OE style here though as the ball joint toiletbowl setup does work nicely. Even if it doesn't flow the best. My car needs boost sure, but its not really going to be about ultimate power. I want daily driver and OE reliability more than extreme power.

June 04, 2009

Didn't get a lot done yesterday, but enough to be happy something was done.

So first thing was fitting the harness and getting a few more items set into the engine bay. As always a perfect fit.

What I am not happy with is the nasty intake manifold. The 2.0 on top has to go and it just looks out of place on an otherwise clean engine. Don't feel like putting the effort into welding it clear and polishing it down though as its gong to get cut out soon enough anyways. I am thinking JB-Weld and painting it white...

Yep theres a vacuum advance dizzy with the hard to find retard can sitting in there. And yep that is an EMPI beetle cap! I am very tempted to run that dizzy mainly because I can. While a locked dizzy is required or recommended for MS, an unlocked one simply means the timing maps are left at zero except where you need to change and modify the timing.

Well fitting the harness and MS required putting some of the interior back in. So I tackled this little project. I have fallen in love with this little tool from Harbor Freight!

Wish it came in metric, but since its Harbor Freight it comes in cheap. I like cheap even more than Metric. Its a nut-rivet tool. My car had the spots for mounting the kneebar, but nothing in the holes.

So after a good cleaning and some vinyl painting I had this.