You must be logged in to rate content!

7 minute(s) of a 217 minute read

7-27-2010

Well as some may know I'm in the process of building a 2000 Camaro Drag Radial Car. I have gotten lot's of email's from people wanting to know the details. As anyone that has built a car knows it is tough to get it all sorted out when you are starting from scratch. What I did know from the start was that Dennis and his crew over at DMC Racing were building the car. That was the easy part and now I had all the time consuming things to do.

Well every project needs a name. So with the help some friends the name I chose is RADIAL-ation. Brian Lohnes from Bangshift.com is the actual one that came up with it and I feel it fit well. So after the name my next step was to get a rendering done so I can send it out to media people or companies who will penitently help with support of the build. So I contacted Greg Zoetmulder of GregZ Design and had him whip me something up and here is what we came up with.

The car be will be powered by a 439ci LS Series small block sporting a single Billet Wheel 106mm turbo. To make sure I come up with the best possable drive train combo I'm working very close with Don Bailey and Billy Briggs. The car will also be tuned by Don and Billy will be assembling the motor. While all motor details are not final I can tell you what I do know. The base foundation of the engine will be a RHS Tall Deck Aluminum block prepaired by Charlie Weston of Weston Machine. On top will be a set of Performance Inductions new generation Canted Valve Moses Heads. The heads will be furnished with Xceldyne Titanium Intake and Inconel Exhaust Valves and will have PSI Springs holding them in place. Jesel Valvetrain Innovation will be supplying the rocker shaft system, keyed .937 lifters, Tapered Pushrods and belt drive with a distributor mounted on top. Inside the engine will be CP TurboPistons connected to Carrillo H-Beam Rods being spun by a Billet Center-weighted Winberg Crankshafts. A Dailey Engineering SP Series pump will be getting the oil through the motor while their Billet Aluminum pan keeps it all in. Finally it will all balance out with a ATI Super Dampers up front and the 2000+ HP going through the ATI SuperGlide 4 Transmission in the rear.

As I mentioned earlier DMC Racing will be building the chassis to NHRA 25.3 specs to make sure it keeps me safe. For the base foundation of the build I will be using a new state of the art design chrome moly light weight front end and chrome moly fabed rear end supplied by Midwest Chassis & Performance. DMC will be using their own custom design for the rear suspension and torque set-up. On all four corners will be Mickey Thompson Wheels and Tiresmaking sure the car hooks up.

I hope everyone enjoys watching and following my build and I will try to update it as much as possable. As you all know these builds take time and some weeks things will go fast and others take longer then expected. I also have been working hard on getting some great media coverage for the build so you will be seeing it pop up on many of the performance web sites, chat boards and even some published magazines. So keep your eye out for it and as the saying goes " Rome wasn't built in a day". Thanks Ed

Special Thanks to the following Project Supporters

DMC Racing

Billy Briggs of Motorcity Speed

Don Bailey

ATI Performance Products

Midwest Chassis & Performance

Jesel Valvetrain Innovations

Performance Inductions

CP Pistons

Carrillo Rods

Winberg Crankshafts

Dailey Engineering

Xceldyne

RHS / Comp Cams

Anyone interested in being involved with the build feel free to contact me at

[email protected] for more info on media coverage or involvement.

It has been some time since I updated with some info and wanted to post some pictures of parts that I have gotten in the past few weeks.

Here are some pictures of the 4.100 Stroke Billet Winberg Crankshaft. It was superfinished to a 1RA finish.

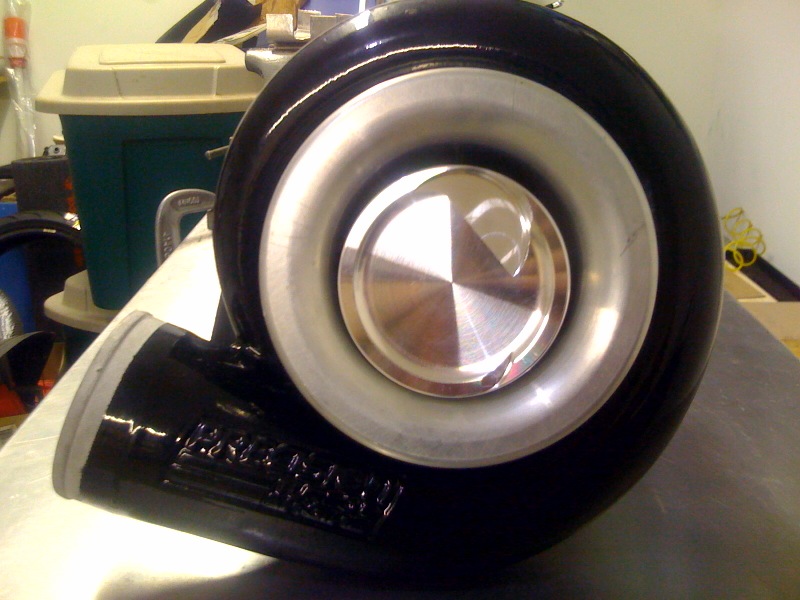

My Turbo. It's a Billet Wheel 106MM

Close up of the wheel

Just to get an idea I put my CP Piston in it. I guess you would call it a turbo piston.LOL

Next up are the CP Piston. CP built me the best that they have. They are 4.128 Bore size.

Top and bottom

Side Shot

I did a little work making sure their are no sharp flash points on them. Time that will be well spent and worth it before they get a coating put on to them.

A little before and after

Holding the Pistons will be a set of 6.450 H-Beam Carrillo Rods. In the design process we made sure that the beam area will be strong enough to hold up to 2000+ HP.

Letting the air in will be Xceldyne Titanium 2.250 Intake Valves and letting it out will be 1.600 Inconel ExhausttValves. The Intake side has a CRN Moly Coating to keep things slick.

I will be sure to post some more things in the next few days and keep everyone updated as much as I can. Thanks for looking.