You must be logged in to rate content!

5 minute(s) of a 217 minute read

7-28-2010

the car will never make it out this season. I will plan on testing with it around Jan. Waiting on all the motor stuff really put it behind and I'm not going to rush it. Next year I have plans on running some of the races but not until I feel it running the way it should.

Phil

The reason for the steel rod is I chose to work with Carrillo. I feel a steel rod will last a lot longer then a aluminum one. It also has a lot less stretch and movement going on. These should be well more then what is needed to handle 35 + LBS of boost as long as the tune-up is correct. We both understand how much that means in any motor. A turbo is really not that hard on the rod. More people think it would be worse but it always has a smoother and more even pressure load on it vs a NOS motor. Speaking to Carrillo they fell the turbo is not that hard on rods.

A lot of engine builders are going back to steel rod. Heck Pro Stock Car are running a 1.8 journal pin reving them to 10,600+ and have 0 issues. They were going through aluminum rods every 30-50 laps and now their are guys running the whole year on 1 set of steel rods with 100+ runs.

As for the reluctor wheel. I will not be using it to fire the motor but I can still put a sensor on it and do other things with it. It can come off very easy but shouldn't be in the way.

I will be using a external wheel. I just have the one on the crank incase I ever wanted to use it for something down the road.

To tell you the truth I'm kinda unsure on that. I had a Magneti Marelli unit I was going to use but I'm still not sure on it yet.

I have looking at the Motec M800 or Big Stuff. Their are +'s and -'s for each unit. I also have 1 or 2 other options of working with some very high end stuff but I don't know if I have time needed to really help them get up and going. I will really need to get moving soon on it since I want to run this thing on the dyno by November.

7-30-2010

Well I must say it really feel's like Christmas, but in July.

Today I got some more of the parts I have been waiting for. The first thing I got is the base of the whole motorbuild.

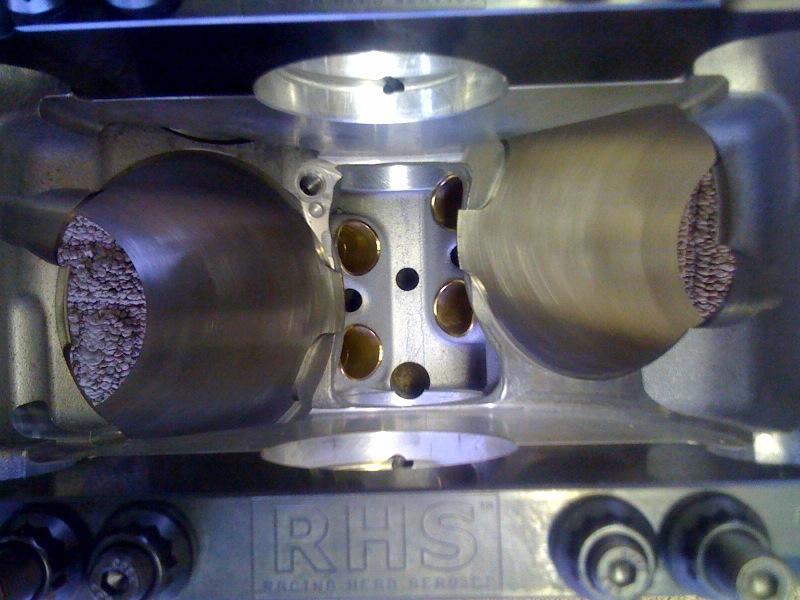

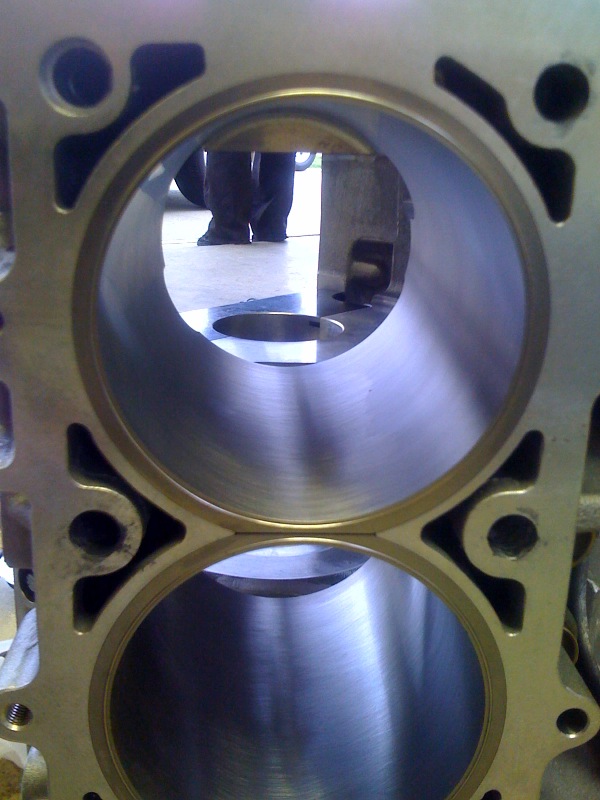

My new RHS Block fully machined by Weston Machine in NJ. Charlie is know for doing some of the best machine work bar none. He machines almost every NHRA Pro Stock car block out their. He also does a lot of LS stuff. So anyone looking for machine work check him out at http://www.westonmachine.com. Here are some pictures and what I had done.

The RHS block

Side Shot

Cylinder Shot

Under Side

O-Ring Done

I also had Weston Machine do the bushed lifter bores to run the Keyed .937 Jesel Lifters. When it comes to lifters they are the best. I will be using 8 center and 8 offset .150 to make sure the push rod angle stays stright.

Take a look.

Bushings from the side

Picture from the top

Box of lifters

Lifter Shot

After I got the block I learned that no one offered a belt drive system for the RHS block. Since I was already working with the Danny Jesel and Bob McDonald from Jesel I had them build a belt drive set-up for me. This system is now offered as a stock item and anyone can call up and buy one.

Their is some machine work required to make the back plate work but it is well worth it. I just can't trust a chain spinning this thing at 9,000 + RPM. Here are some pictures of the very first Jesel RHS Belt Drive.

Back Plate

Machined Block for plate to fit

Belt Drive Set-Up with cogs

Belt Drive shown with optional distributor Set-up

I have a few more items but everyone will just have to wait until I find a little more time to get them up. I plan to try and update everyone as much as I can. Thanks for following.