You must be logged in to rate content!

11 minute(s) of a 668 minute read

5-28-2015

Thanks PostaljeepSS and huntinrig.

I mentioned yesterday to someone that we can have a vision, we can have a plan, it's the ability and patience to see it through to the end that is the tough part.

For some time now as people asked about the paint and finish I would answer, yet feel a slight doubt since I haven't done much paint work for nearly 20 years.

It is now that I can rest my mind, settle down and enjoy the project and get working on so many odds and ends.

huntinrig, yes, I am ready to chat about the truck. As we follow along the build we can see that I installed most every nut and bolt from drive train, suspension, brakes, and body ect.

I'm not trying to sound proud, I am replying to the kind compliment you

made about sharing my knowledge. It is great discussing my projects and not having to pause, do to something I paid someone else to do and I don't know the inner working of something.

By at least rolling back the cover and exposing the inner workings of engines, transmissions, rear axles, body and paint, I hope some have grown in their abilities because some of the mysteries have been exposed on this thread.

Back to assembly, Jim

7-1-2015

For about 3 years now.... ee-gads, 3 years already, I've focused on the 57 Chevy truck. Yes, it's been one project, one build, with no interruptions.

Is it worth stopping all other projects to focus on one project? I suppose if that is what it takes to achieve a certain outcome, that is what needs to be done.

I have approx 200 miles on it now, other than a few odds and ends, it's been pretty reliable so far.

I have a couple more pics to cover, mainly finishing up the seat support frame.

Here is where I stopped when the truck was in primer.

It provides a lot of storage space but I want the ends to be covered. Using the bead roller of which isn't very expensive, I added a decorative touch to it.

Slowly doing tack welds I welded the sheet metal to the seat frame.

After the welding I cleaned the welds using the 40 grit flap discs. Then outside for a quick sandblasting.

Personal opinion time...... I read and follow many paint and body work forums. So often I read where others are scaring people away from sandblasting because of harmful breathing. I have one idea.... then wear a face mask. I have yet to see a procedure that will clean, remove grinding scratches and leave the perfect surface for epoxy priming than sandblasting gives when done.

Just check out the next picture, sure I hate sandblasting with all the sand everywhere but the result is a perfect final piece.

I did use a small bit of spot putty and by my finger I applied it along the edges, then used sandpaper to to finish the job.

Then 1 coat of epoxy and 2 coats of satin black.

With most of the interior finished.

I finished most of the truck, at least enough to go to a car show. Long story short, I qualified for 4 different categories, in all 4 categories I took 1st place.

The best award was "best of show" vehicle, it also has the biggest trophy. I rarely include myself in pictures, but here goes.

I rarely include myself in pictures, but here goes.

What a perfect day to show what happens when you push as hard as you can to do your best work. I think the paint was a huge surprise when I said I did it myself in my own work shop.

Thanks to all you that have followed along and encouraged me during this build thread as this Chevy has been given a brand new life. Jim

7-7-2015

Thanks everybody. As I go back about 3 years on this forum and review the many pictures and the progress it took to get this truckshow worthy, I can still feel many of the triumphs and set backs along the way.

I can also remember I figured I'd be done with it about 2 years ago.

It's not so much how we handle the triumphs that gets the project where it is so much as it is how we handle the set backs. Last night a friend of mine stopped by needing a bracket made for his flexible transmission filler tube. As I was making and shaping it I mentioned if I didn't like how it is coming along, I'd toss it into the scrap pile and start again. As I mentioned this to him I pointed to a pile of stainless, aluminum and steel, all with fancy cuts and contours. This pile and pointing it out was to bring forth the fact that when fabricating, there will be sacrifices made occasionally to get the desired look.

I mention this so no one gets the idea that fabrication is easy, hours and hours go into the simplest piece. But when your done, it is one of a kind.

I'm glad with technology that many of you have been able to follow along and I appreciate the many comments of how this thread has helped to teach patience and perseverance and how this build thread has taught to stick with the project through out the good times and the rough times.

My intent with this build thread was to document thoroughly enough that people following along would feel the progress and the thought process necessary to to keep moving forward and to keep focus on the final outcome and not be focused on all the work needed to get to the final outcome. So far I think the build thread has grown very well in the direction of allowing people to become a part of each build and I thank each of you for helping to grow a build thread that has stayed true to it's nature of teaching and inspiring.

Thanks again everybody, Jim

12-7-2015

Thought I'd check in and see if there has been any action, looky here, a new post.

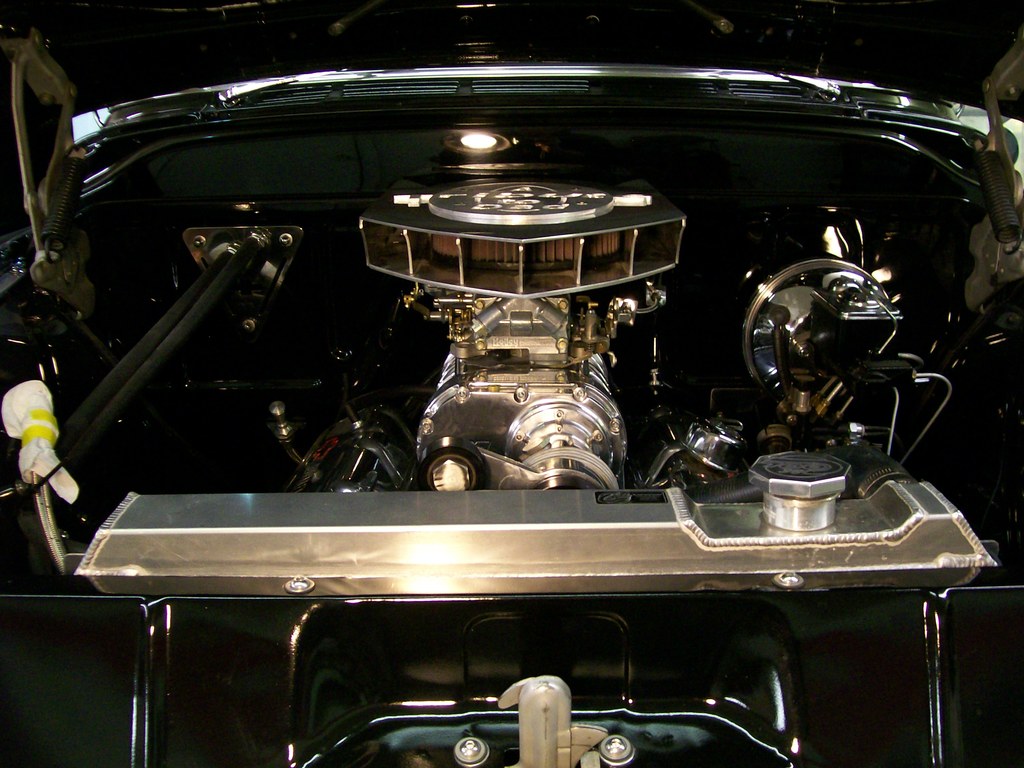

Been to a couple of car shows and brought home more awards. Other than that I've opened the hood many times with the feeling I can do more, it needs more under the hood, and if I gain more power with doing more under the hood, well that's a huge bonus.

I decided to venture down a different road, a road not traveled often, yet, a road we all would like to travel down some day.

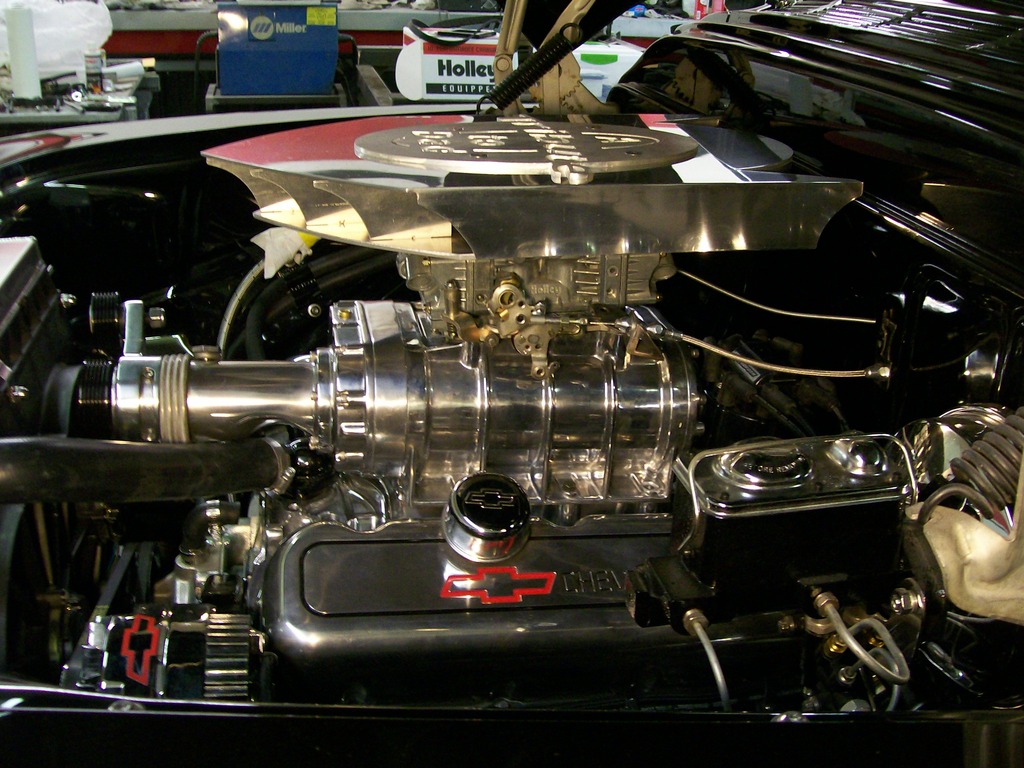

After spending hours reading about Superchargers/Blowers I felt it was time to learn to boost. One of my concerns was being able to drive long distances with a blower. I found Weiand makes exactly what I'm looking for.

The key for me is the serpentine belt drive, self adjusting, quiet, simple to work with. NOTE.... it will not have the loud whine as the toothed belt style has, although I love the sound of a blower, as we all do, I need long term drivability along with the forced induction.

Took some time getting all the pulleys readjusted to fit the blower belt and succeded. Yesterday was the first start up a test drive.

These are some mock-up pictures.

The test drive was so good I couldn't stop thinking about it today. It runs and drives just as it did before the blower until you get heavy footed, let's just say we went sideways through a couple of intersections yesterday.

What I am also exciteded about is.. I have the wrong carburator, wrong cam and wrong heads for a blower to run at it's best. This winter the engine becomes a blower happy engine and I can't wait for next spring.

There's a brief catch up on what's going on.

12-10-2015

Thanks guys. Fun is one word to describe the drive.

Anticipation is another, always looking for the smallest reason to lay rubber.

Gojeep, just as with this '57 is there is space under your hood for a blower.

Mine is a 177 series, for a smaller engine there is a slightly smaller 142 series.

As for driveability, so far mine is like a normal carb set-up. Idle is fine, just as before. Starts quicker than before, the paper work mentioned that it would. Normal acceleration just as before, just a little more sensative. Sound wise, it's a serpentine belt so the loud whine is gone. Going down the road, if you've been in a jet plane and know the sound from the jet engines, very simlar to that sound. You can hear the blower and appreciate it, yet, when not paying attention to the sound you forget it's there.

Burn out from dead stop, be careful, you'll need to feather the pedal, it'll rev quick. Burn out from a slow roll, you'll feel the blower build boost very quick, if the tires break totally free, you have to feather the pedal. If the tires are hooking well, you'll be accelerating fast with the tires clawing for every bit of traction.

In my opinion, I don't see much change in highway mileage, yes, keep your foot out of it.

I look forward to next spring, as soon as our weather turns ugly, I have engine changes to make over the winter months.

My cam is not right for a blower, too much overlap is allowing boost to escape out the exhaust valve.

I have small ports and small valves in my stock heads, the heads will be changed also to a better flowing set of aluminum ones.

They recommend a 750 to 850 carb, I have a 700 right now, the carb will be changed.

I now have cast pistons, new forged ones are on the way.

You'll notice it was a simple 396 engine, remember, I was building it for my Dad to drive whenever, where ever. Now that I have my vision now of how I want to finish this up, it's time to beef things up.

With the upgrades coming, I realize the rear tires are going to take a beating. If next year continues as the last week has, I should have burn out marks at every intersection in town.