You must be logged in to rate content!

4 minute(s) of a 39 minute read

10-24-2009

Well, the engine block and crankshaft went to the hot-tank yesterday. The man said it may take several dips and a couple weeks to get it really clean. He uses the real deal, boiling caustic. He says the jugs have a lot of taper to them, but I explained I can't afford to rebore it right now, but would sure like to. That can come down the road. This is going to be a daily driver, so the engine will probably be coming back out again someday. He looked at the main jounals and was impressed with their condition. I liked that. However, the shells show signs of age (cracking, etc), so the bearings will be replaced.

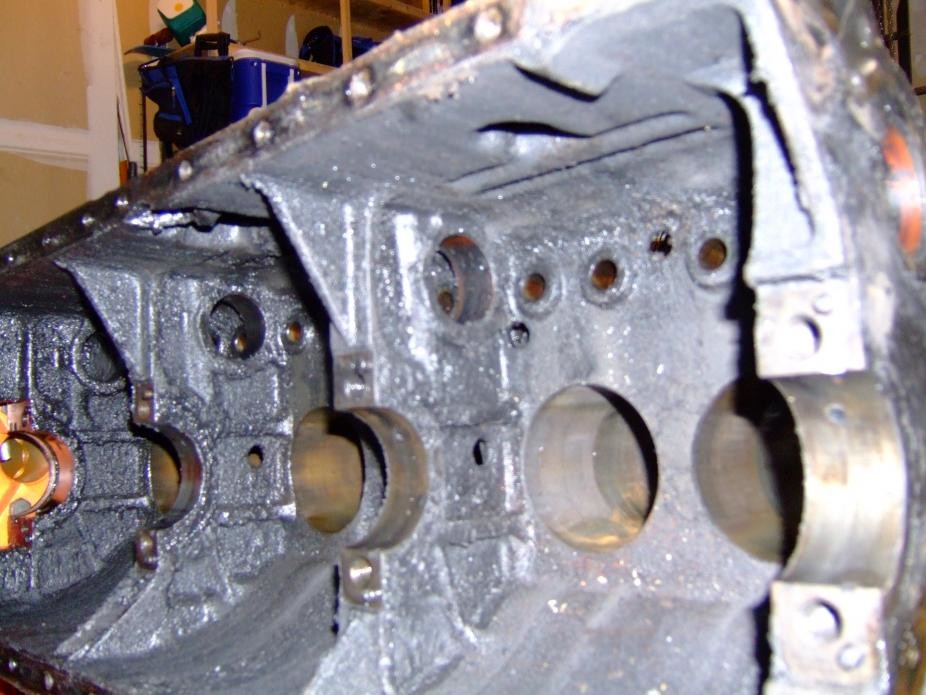

I asked him about some scary looking cracks down the left side of the block, but he agrees that they don't look like actual cracks. He says they look more like a crappy casting job. We will see when it comes back.

He also clued me in as to why the old greasy oil from the engine is so incredibly messy; tracks everywhere and hard to remove. A lot of the oil back then (this car hasn't been driven since the early 60's and probably had even older oil in it) was parrafin base. So I have been experiencing a dirty, waxy oil. I will be glad when that's all gone.

I will put up pictures when I get it back. :cool:

11-10-2009

The block is in its third week in the hot tank. Should be done this week. Said the shop,"that thing was really nasty!" I actually cleaned it a lot before I took it in.

12-5-2009

Well, we finally got the engine parts back from the machine shop. We had the block, head, crankshaft, camshaft, and oil pan hot-tanked.

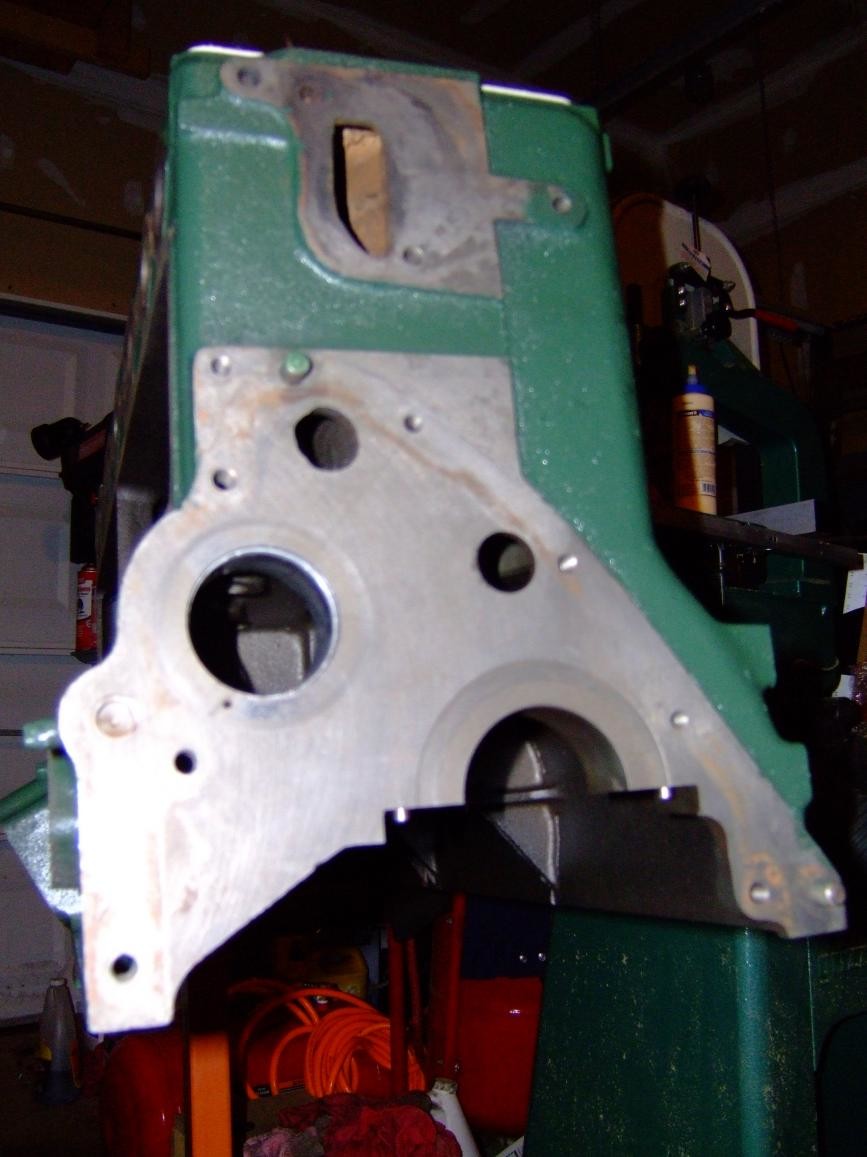

The openings for the cam bearings were so tight that he had to line bore the bearings after he installed them to get the camshaft in. The "cracks" in the block were verified to be a bad casting after all. The crankshaft mic'd out beautifully and the rod journals are all within a 1/10,000th of each other and still in the factory specs! We ended up buying new mains and rod bearings. That is really the ONLY way to do it right, although the mains were in good enough shape that the shop said to keep them for spares. Good idea, since I got the last set of std's from Egge and they said they probably will never make any more.

Somewhere, I have misplaced the three camshaft gear bolts. Along with that, I can't locate the spring or thrust plunger that go in the end of the shaft. I sure hope they are together somewhere!!

We decided the valves looked good, so we just lapped them real good. We then installed them, the springs, lifters, camshaft, and crankshaft. We had to trim the vertical cork inserts on the rear main a little to get the cap installed. Sure hope it doesn't leak, but it was impossible to install otherwise. We left a little extra in length so maybe the oil pan will squish it into a better sealing situation.

Now we will rebuild the fuel pump and carburetor. We will wait on the pistons, as the weather is bad and they need cleaning. I do most of that outside.

Here are a few pictures to show how it is going.

Love this build. Got an classic Olds running and a new generation into wrenching. Interested to see where its at now!

Posted by stevegolf on 12/3/18 @ 12:09:43 AM