You must be logged in to rate content!

7 minute(s) of a 255 minute read

1-22-2022

Cleaned the goop off the liners and will have to do it to the block soon.

Removed the flywheel from the crank, ordered another set of 0.3 mm oversize bearings from Dean Hunter in case the crank does not actually need a regrind.

Monday it goes into Mid-Island Engines and Machine Shop in Duncan, along with a set of 0.5 mm oversized rod bearings (the 0.3 set is en route as of Friday), the 4 rods with pistons attached so Chuck in the shop can check the roundness of the big ends....

It seems that Coachwerks, who restored my bodyshell and recommended Anderson's, is now using the shop my crank's going to. I suppose we both experienced some issues at roughly the same time.

Chuck warned me that it could be a while because his main machinist is working intermittently and he may have to do the work himself. It'd be nice to get it back at the end of February.

3-11-2022

Got another set of 0.3 oversized rod bearings in case Mid Island Engines can smooth out the burrs short of another regrind. They're super busy and so it may be another month or more before it's ready.

Got to get the brake hydraulics sorted now during the wait. If they're done, and I connected everything well, it'll be ready. Then the road trials begin. I'm sure there will be lots of fine tuning needed.

3-26-2022

My 1966 404C restoration is stalled right now for two reasons: the second machine shop has the crank for a refinish after the first shop literally made a hash of it, and I cannot for the life of me get the brakes to bleed.

On the brakes, here is the background: new master cylinder, newly rebuilt brake cylinders (the car has the Hydrovac booster, rebuilt), all new rubber brake lines, rear brake proportioning valve unique to the C model (limits pressure peaks) is the old one but not leaking, and most importantly I think, I remade all the brake lines in Cunifer tubing, 3/16". Cunifer is a copper-nickel-iron alloy in case you haven't heard of it. The original brake lines are steel.

So, one small detail also is that the original hard brake lines have UNF imperial sized threads but 10 mm heads. I could not source these over here in Canada so I used the same UNF threading with a 3/8" head, which is about 9.5 mm.

So, using the original brake lines as a template, I bent up a complete set of lines for the car, and made the ends with a good quality hydraulic flaring tool.

When first installing the lines, I used a 10 mm brake pipe wrench to tighten them and therefore wasn't able to get them tight enough to seal without the wrench rounding the nut head. Remembering the size difference, I got an imperial sized pipe wrench and cranked them tight.

I first tried to bleed them with the original, unrebuilt Hydrovac booster in place, using a Pela oil extractor pump to provide 30 lbs of vacuum to suck air out of the lines starting with the RR wheel etc (LHD car). I could not get a clean bleed, with an airy froth coming out. Blaming the old Hydrovac, which was NOS in 1993 and probably suffering from 20 years of being on the essentially unused car, I bought a rebuilt one from a friend in Boston USA.

Before installing it and going through the same thing, I decided to remove the old Hydrovac and connect the hose from the master cylinder directly to the distribution lines, to make sure I could get a clean bleed first, to eliminate any possibility that the Hydrovac would be the cause. Well, even after tightening and retightening every line, it's still frothing and there is "no pedal" if you know what I mean, the lines are sucking in air all over, so it seems. With no pedal, I can't pressurise the system to see where the leaks are.

In hindsight, here's the thing that didn't seem right: with the original lines and fittings, they behaved like normal bolts, being relatively easy to turn until the very end. With the ones I made, they got rather stiff as they tightened, to the point that I really had to wail on them to get them fully home, and even then I doubt that some are actually tight. I wonder if the new threading is actually correct...

I still have the original brake lines, but they're 56 years old and probably are rusty inside (I could clean them out with acid I suppose!), but one of them was broken when disassembling the car - a short one connecting the two front brake cylinders. But I'd rather use all new stuff.

With the engine still on the stand, it's easy enough to get under the car an replace everything again, so if I can identify what on earth is the issue, which is why I'm posting this, that would let me make new lines or use different fittings or whatever the actual issue is.

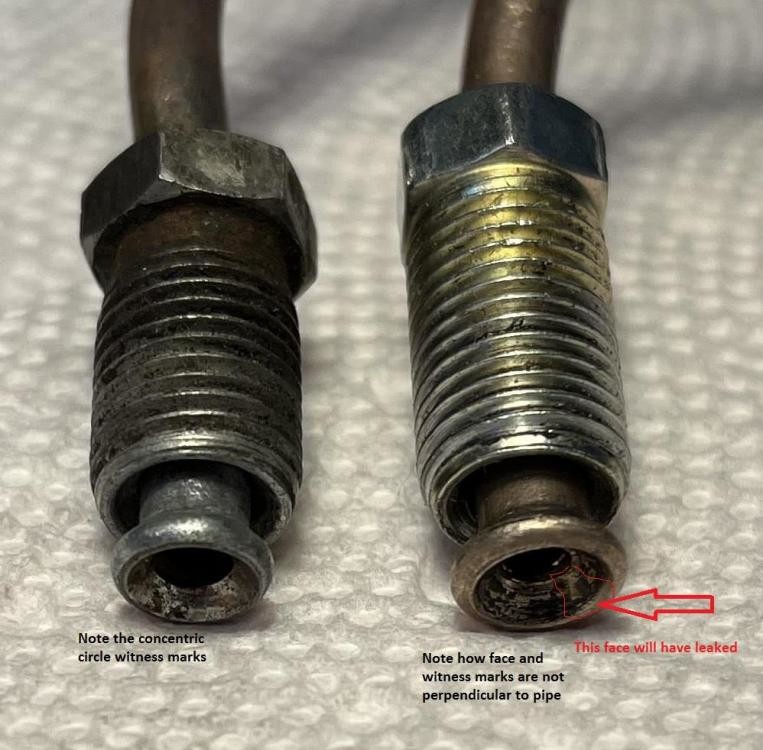

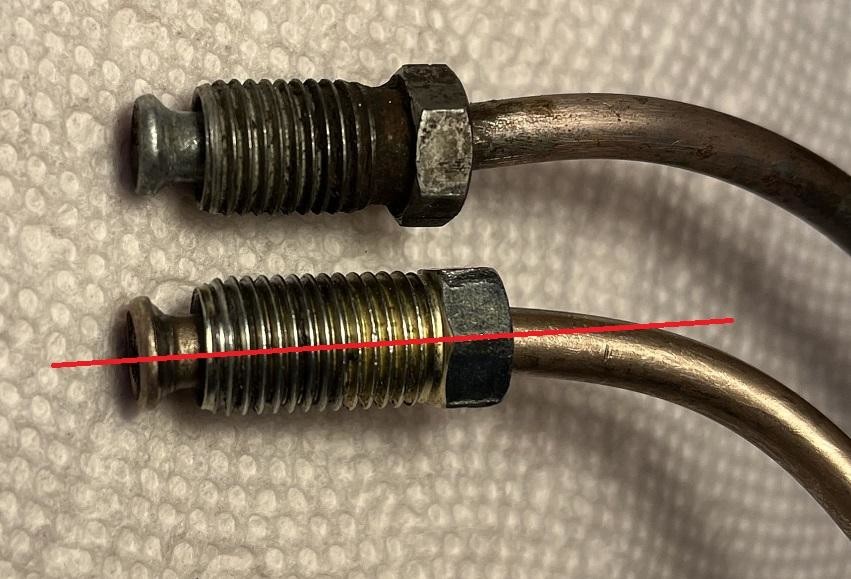

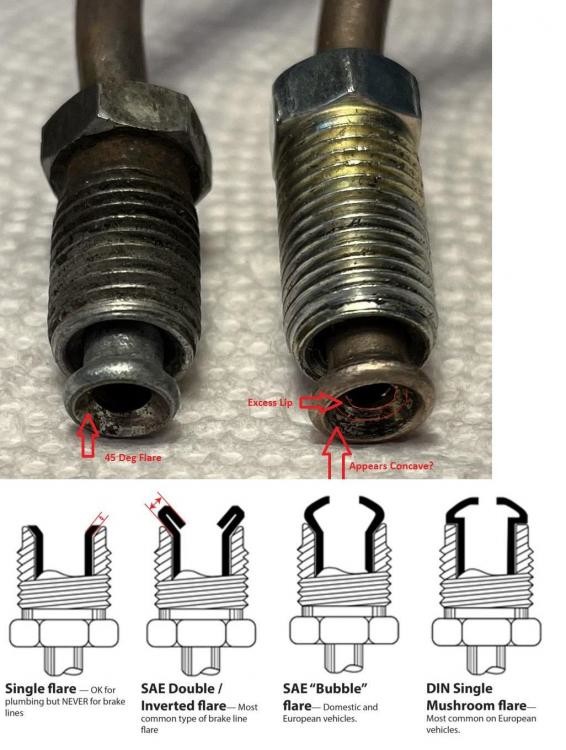

Here are some photos of the ends of an original brake line and one I made, so maybe any errors in the shape of the fitting or whatever can be identified. Any advice or tips will be gratefully received.

I think I'll get some new fittings from Europe and start over. I don't know anyone with a Motive but it would be nice.

3-28-2022

I have a few tips now: firstly, I have ordered the proper 10 mm with 24U from Serie04 fittings for the lines and I also think that I had the end of the tubes too far out of the block when making the flares, and that messed up the sealing. So now we're going to make a new set up and hope for a better result....

Some members on Aussiefrogs supplied the following doctored photos to help the diagnosis. Also, it was correctly noted that the bleed screws themselves are super clean and those threads will be leaking with a vacuum bleeder. So I have some robust ideas to follow up on the next go-round.

Wow a labor of love. Great!!

Posted by Diggymart on 9/7/19 @ 4:02:23 PM