You must be logged in to rate content!

3 minute(s) of a 388 minute read

9-15-2016

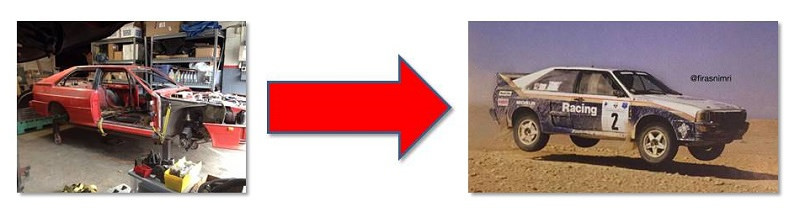

As our 85 UR quattro is getting to the point of being on the road again I'd like to introduce our latest project which we plan to start almost immediately. A 1983 UR qauttro, currently in such a sorry state that it's only viable future is as a RALLY CAR!

The shell is pretty solid and the car "ran when parked". We will be rebuilding the engine and transmission and it does have this hole in the rocker panel.

We picked up the car about a year ago quite locally as it happens. The previous owner had driven it for about five years then decided to put a cage in it and use it as a more dedicated track toy. He stripped a lot of the interior out, bought some go fast bits, put a rudimentary cage in it and then got distracted for about twelve years. That's when we cam along and "saved" it.

It came to us in the stripped out condition you see but with some interesting bits; some attached, some not.

Koni based custom coil overs:

Rally rear spolier.

Fiberglass front fenders

NOS kit!

Audio

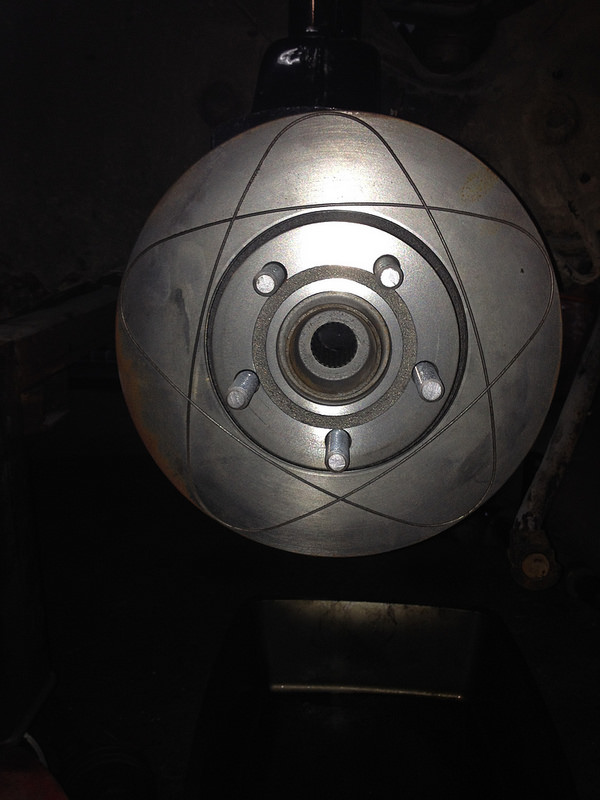

Refurbished brake calipers with new discs

Fiberglass S1 (short wheel base) hood

and all the parts that came off it in a trailer!

So the plan is to strip the shell, fix the rust, install a cage, install a Group B body kit, and rebuild it as a Rothmans tribute to match our Porsche 911 Carrera RX and Mercedes RALIVAN. Stay tuned.

Comments

Great update!

Posted by Diggymart on 10/10/21 @ 10:31:32 PM

Great build

Posted by tmprod on 3/4/21 @ 6:44:07 PM

Thanks for updating Paul! Ill have to check out your new shop soon!

Posted by diyauto on 12/24/20 @ 5:08:37 PM

Anytime.

Posted by team illuminata on 12/24/20 @ 6:34:09 PM

This will be a beast when finished, looking forward to it.

Posted by MPower on 10/12/20 @ 2:15:11 PM

Great build!

Posted by DIYauto_Admin on 9/9/20 @ 12:08:22 AM

Hey hi Sue!

Posted by Diggymart on 2/14/20 @ 4:12:57 PM

Looks like it’s coming together!

Posted by Diggymart on 11/21/19 @ 2:49:00 PM

Those stands look nice!

Posted by diyauto on 11/21/19 @ 2:47:08 PM

Incredible build! Love the photo's

Posted by MoonpieMagic on 11/8/19 @ 8:00:45 AM

Thank goodness for friends carrying precious cargo!

Posted by Diggymart on 10/10/19 @ 11:40:08 PM

Woo! Excited to check this thing out soon :)

Posted by diyauto on 9/13/19 @ 1:37:14 PM

Great teamwork!

Posted by Diggymart on 7/29/19 @ 3:11:58 PM

Great build!

Posted by Diggymart on 1/17/19 @ 7:24:29 PM

Thanks

Posted by team illuminata on 3/4/21 @ 10:30:06 PM

Lookin good. Pride in work and attention to detail

Posted by Cyphercrash on 3/5/23 @ 8:59:32 PM