You must be logged in to rate content!

6 minute(s) of a 464 minute read

4-1-2006

AFGMOTO1978 Build Thread

Compliments of afgmoto1978 @ www.rx7club.com

9-26-2012

Okay so if figured where I documented my build way back when wasn't where it should be. So here's a rehash of the build with a lot of the fat removed.

This build all started after having a very disappointing engine blow-up (motor three) at the track while running out of gas. lol

So what was going to be a basic build up became a five year and counting constant modification.

So enjoy!

4/3/06

"

Well, the motors out of the car and at Pineapple for a rebuild. Damaged the rotor bearings by starving them for oil and then detonating on top of it when I ran out of gas at PIR. Hopefully that's the only major damage done to the engine. Apex seals a Ianetti's and they look fine.

Starting to strip the car for a proper paint job instead of the Matco Special I have on mine.

Just got my SSR Comp-H wheels (15lbs each) and V710 tires in last week too. (Miss these wheels and those were great tires)

Things to do/get still:

Raceshop four point cage

Delrin Bushing kit (in the mail)

AutoExe under chassis brace and front tower brace (didn't happen, Winter 2012 CF Underbody / Chassis reinforcement in the works, finances willing)

99 Spec plateless front end turn signals, Feed side skirts (In the Mail).

Datalogit for Power FC (In the Mail)

Apexi BOV (Send Check) (Not enough air flow, went with Synapse unit!)

Rebuild Efini's (lol)

Another BOV for Secondary Turbo that I can plum back into the intake track.

Fabricate Custom Y-Pipe

Either fabricate DIY air box or buy HKS Racing suction kit and replace the foams for

K&Ns (By the way foam does jack all for filtering - Apex "Hint Hint")

Custom DIY V-mount - I really don't like what's out there (no ones putting vibration/durability in mind and the end tanks are a joke) and I have access to a full machine shop so why not.

Decide if I want to modify the wiring harness so the battery and all relay/fuses are in the Passenger storage bin, or heat wrap what I have and call it good for now. Majorly time consuming. (Holy Crap I had no idea what a bitch this was going to be)

Modify stock seats, DIY upper to improve lateral support and still fit within cage.

Jesus, this going to be expense and time consuming. "

^So true, lol

4/13/06

Oh ya this gonna cost me $$$$. Spun a bearing and broke a one piece ceramic apex seal.

Enjoy in my pain. Pan'n for gold are ya.

Yaaaa, I wanna go to Hawaii!! Yaaaa

This is still depressing to look at even after 6 years have past.

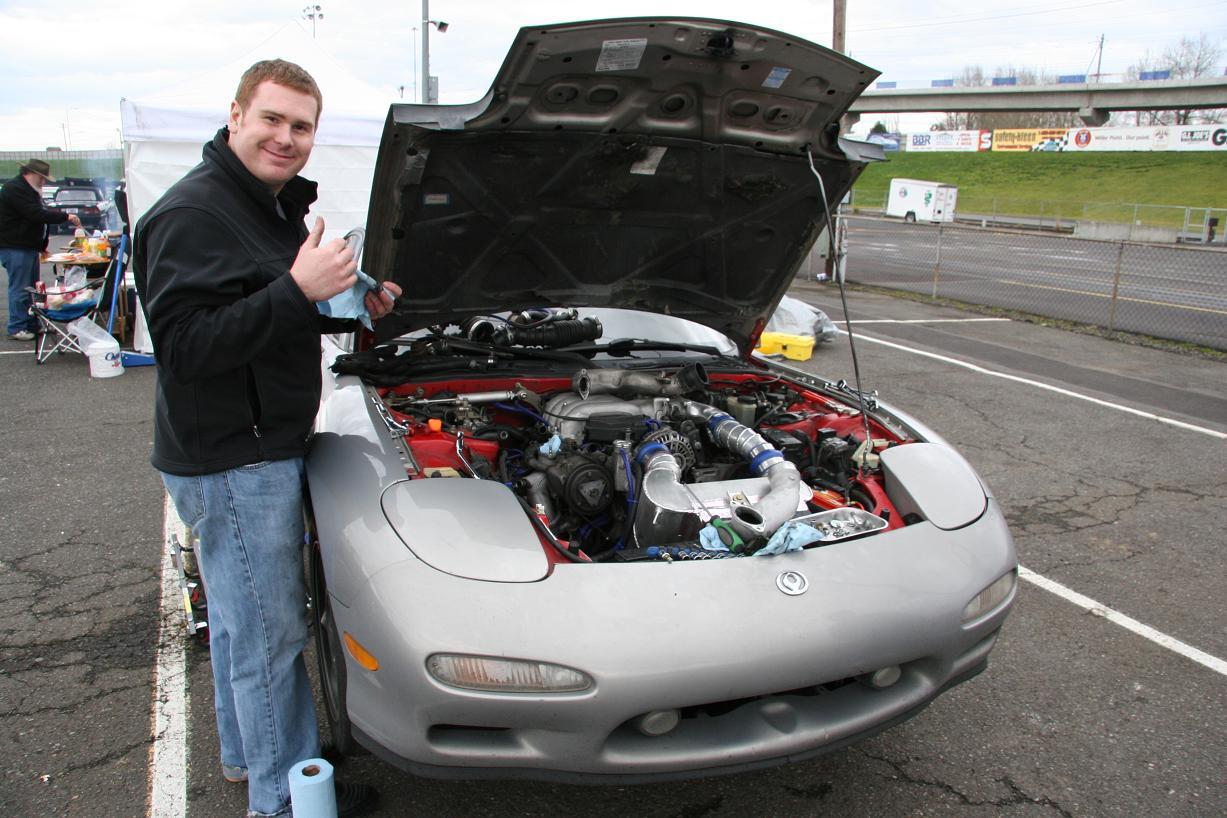

I'm smiling, but I'm crying inside.

Dude, can I use your shop....

Apex...sure (Damnit, another dead beat in my shop)

Without this guy cartapex aka John Farris letting me use his shop and being patient for 4 years while building my car it would have never happened.

Photos of my car the day I blew the motor.

Well found some front end damage repair work on the right front. Whoever did it wasn't very good. Going to have to buy a replacement piece from Mazda and weld it on.

Soda blasting the chassis next week!! Soda Blaster guy is going to pick up the car Monday.

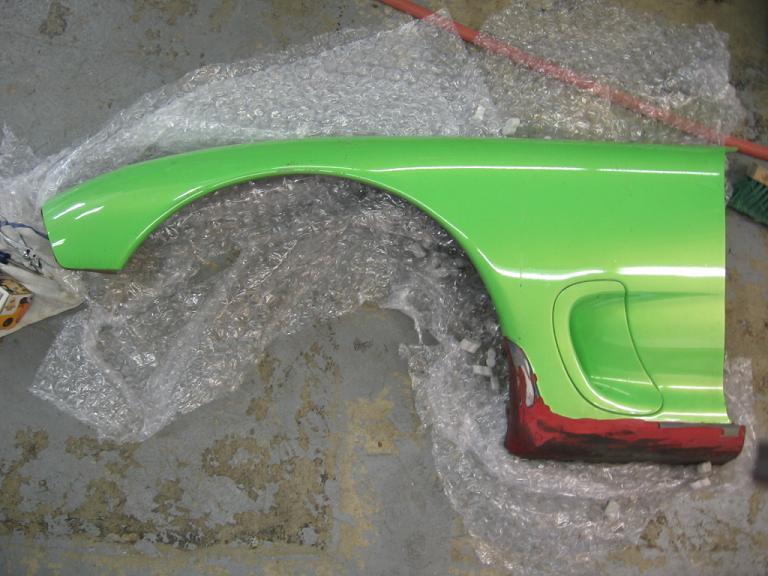

Got the fender that I won off of ebay; opened the package and I was like...WTF?! That's a green fender.

This picture of the interior shows how cheap my old paint job was.

Fender damage, going to have the body shop check if the chassis is even straight.

Nice build!

Posted by Diggymart on 12/10/19 @ 12:54:14 PM