You must be logged in to rate content!

7 minute(s) of a 264 minute read

5-23-2016

We moved from the big 993 oil cooler when this particular version of this car was 'unwrapped' last October. However it was too small and we were seeing temps over 110c. So put in something that was as big or bigger than the 993 and the temps dropped to about 90c peak. With the car primarily used for short bursts we think we'll be ok and have been recommended this path by someone with a lot more experience than me. Looking to use one of these Thom. http://www.laminova.se/

The benefits will be mulitple (provided it works!) but mainly drag reduction by removing it from the airstream and also allowing a diffuser to rise up where the oil coolercurrently sits.

Downforce vs drag vs cooling. To that I add the 4th constant which the engineers overlook....budget.

So essentially the formula is purpose driven. For a T.A. car drag and downforce are paramount. Cooling isn't quite as essential as normal racecars. Of course it's a balance. Yes, only the oil is going to be cooled by water. The Rad and I/c are still air cooled. We are raising the Rad a little purely to make way for the diffusers in the splitter (which haven't been built yet). Step by step. Today's bill was enough for me at the moment!

Just had to post this pic. After a lot of work over the last few weeks it's always a bit of a thrill to see the car loaded up on the trailer ready to go to the track.

Note that the new wider splitter only just allows us to fit. Considering that the trailer was pretty much made for this car by my builder, we didn't take into account that we'd be wider than we were in October last year. ![]()

5/26/14

A little bit of video in and out of the car. As you can see it just wants to throw you sideways a bit but Paul is very good at keeping it moving forwards. Sorry about the weird sound. Need a better mic'd system.

Here's one showing a few of the cars that were running. You see a bit of JET951 and various GT3's the RSR and even a 956 copy.

9/14/14

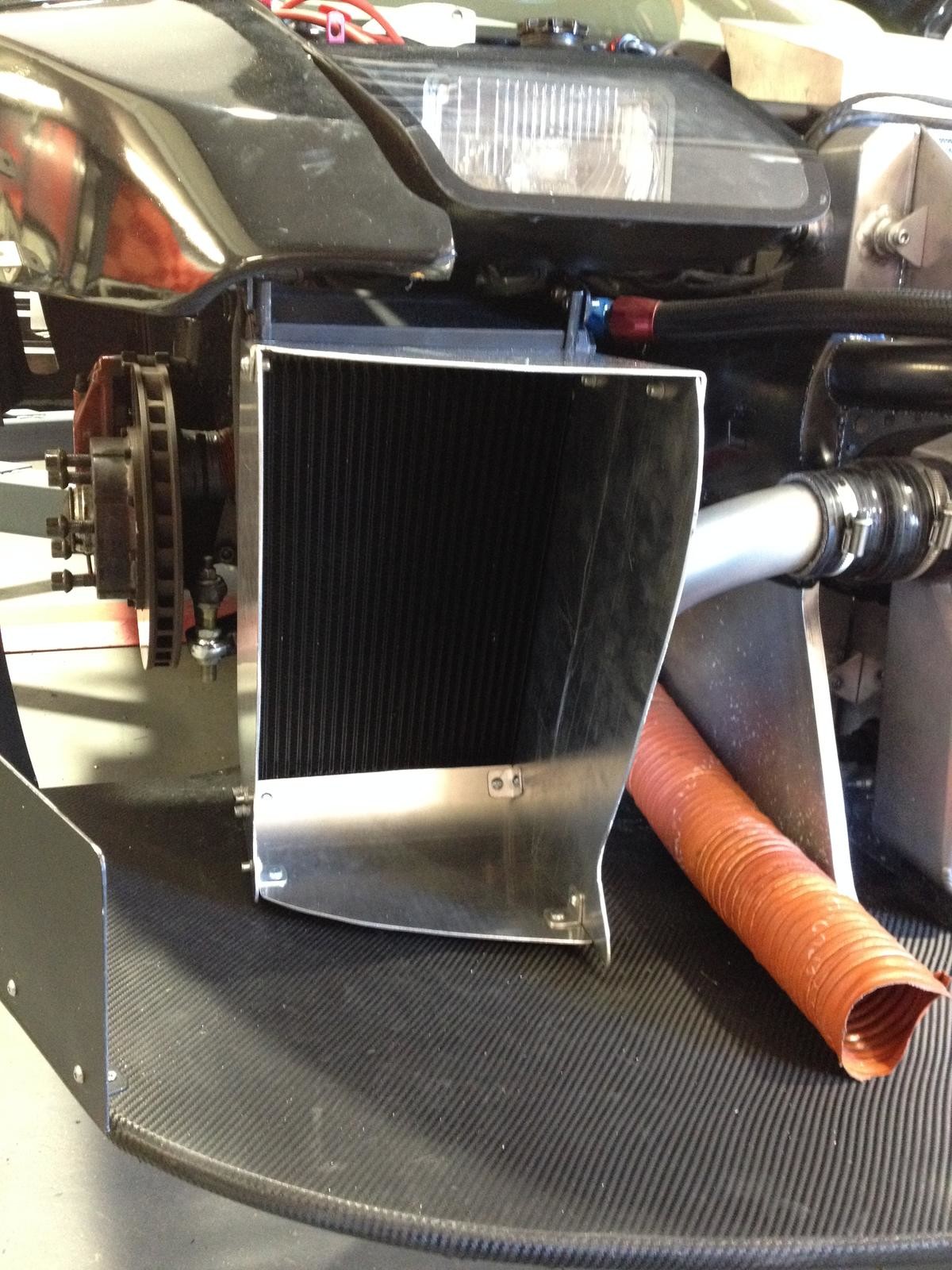

Not posting a lot lately but that doesn't mean changes aren't happening as we speak. Here is the latest showing the new Water to Oil cooler at the front right side of the car. (1st pic showing the previous cooler). We're running out of room when looking at placement not only for plumbing and packaging but also with an Aero viewpoint. The reason we changed from the very effective large traditional Air to Oil cooler was to remove it from the airstream (less drag/front lift) and to also make room for some 'active' aero with the splitter. I can't show the diffusers at the moment as we need to keep a few little secrets from the gaze of the internet but perhaps after October. We will be testing both next weekend. We're clearly hopeful that this little heat exchanger does the trick. They run these on some of the leading Aussie Supercar V8s so we should be ok.

As you can see in the 2nd last pic of the front of the car we will be making changes to what is seen there. The two long vertical holes that are the openings for the previous air to oil cooler will be covered up. Any openings on the front of most cars produce the largest amount of drag which leads to front end lift. So when you can cover up any opening it's a win...however that is always balanced with the cooling aspect. It's a compromise between the builder, engineers, aero guys. They all want things that suit their aspect. The other often forgotten person in that mix is the owner. That is the budget side of the quotient! We will be making some changes to the venting as well. I'm hoping that we can either modify or replace the existing hood vents and also put in two more in the centre. These will have a different appearance in a cross sectional view. More aggressive and steeper in shape. Same with the existing fender vents which are being modified now to have a similar change. Not as radical as Under Suzuki's amazing Silvia but you get the picture. We're looking to improve the underhood cooling as the more we blank off the front bar the hotter it will get under there.

12/12/14

Just adding a bit more on this thread so I can direct people to it who are asking about certain aspects. Rather than me post pics in other's threads that is.

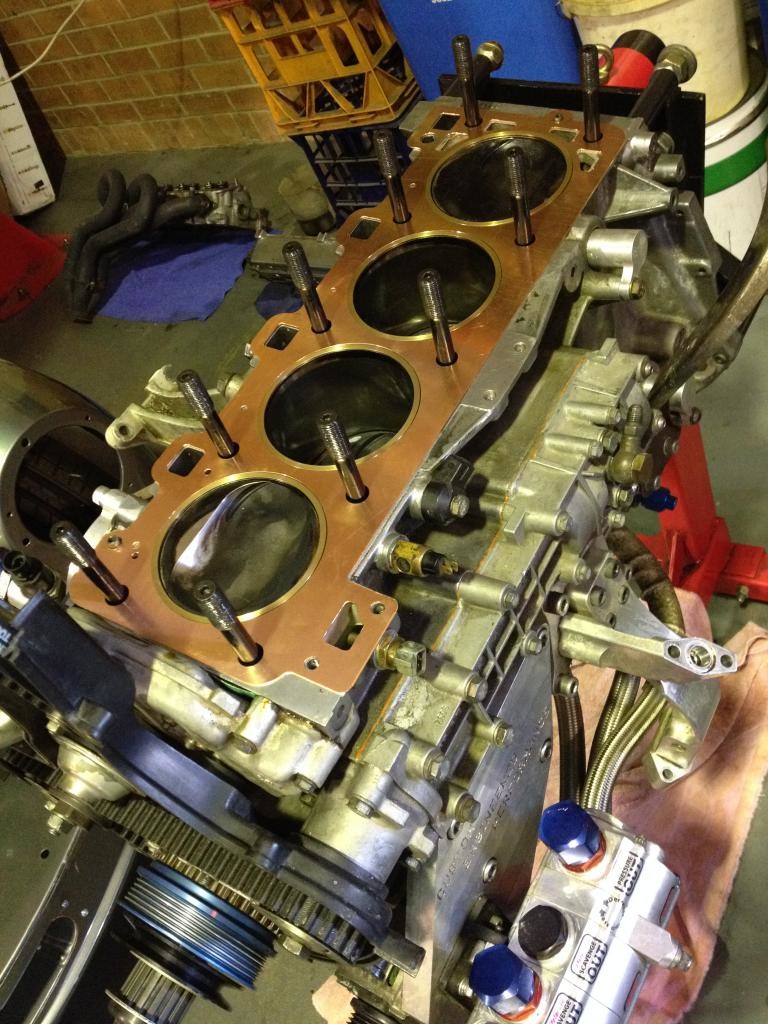

So here is the new 'sealing system' we put into place a few months ago. We had got to the point of having to replace the Cometic head gaskets after every meeting. We also did a little bit of minor damage to some bores by having coolant sitting in the cylinders between taking the head off to replace the headgasket. Minor 'rust rings' I guess you'd term them. The motor is coming apart as I write this and the ring while tactile to the 'thumbnail test' looks like it will respond to a light honing and we can reassemble it with new rings and same pistons. Hope so anyway. A new larger 8v head is in the wings too. More of that later.

So we decided to use a local company to 'O' ring the liners and make up some Beru rings that would sit in the groove. We also had another local company make up a Copper head gasket. So far so good, we've run it a few times on the dyno at 25psi and on the track under sustained boost and we didn't lose any coolant. Really nice when something works straight up. Now that the motor is being pulled down we have found that both the rings and the gasket are in great order and we will be reusing them when we have the new crank and head available.

Wow great build!

Posted by Diggymart on 12/28/20 @ 2:54:22 PM