You must be logged in to rate content!

8 minute(s) of a 391 minute read

7-15-2009

So I been fighting with my shifter adjustment. Stumbled across this thread the other day. http://forums.vwvortex.com/zer...33208 Theres some really really good information in it! And following the links in there I stumbeld across my problem.

Apparently VW made a change up on the shifter box / gate itself. The 4 speed one is differant from the 5 speed one. I never bothered to change that as nobody ever mentioned it. But the metal stop plate on the 5 speed is narrower to allow for more alignment room.

Well leson learned. I will take pictures of the differance when I get the new bit and have the parts sitting out.

July 18, 2009

So, shes running pretty close to tits now. I have a few concerns. Mainly bad knock in this heat when under sustained boost. Heard it a couple times and of course when the computer wasn't datalogging...

I suspect the intake temps were too high. I had this issue before with a similar setup in my cabby. The hazards of running without intercooling.

Other than that shes running hard and strong! I haven't done a whole lot thats easily noticeable. Slowly getting the OE wiring sorted out a section at a time.

Phase 1 right now is to get my KnockSenseMS sorted out and wired into the car. Then I can datalog where and if I am getting knock. The ABA serpentine setup sounds like it sometimes too. Not used to that quite yet.

Phase 2 of this is to get the Aquamist water injection system fully online. I want to rig it up with the MF2 controller for now to just verify everything is working. But I will then get it fully integrated with the MegaSquirt by next weekend.

Phase 3, finally I am going to modify the MS to activate my CEL when intake temps are too high. This will help with the times I am not monitoring the temps on the laptop. I really hate not having a lappy connected and datalogging at all times... AFAIK there still is no plug in datalogging solution. I am not a programmer type, but I think I can get one of these to work. http://www.sparkfun.com/commer...=8627

That reminds me, I have to figure out why my coolant gauge in the cluster isn't working...

July 21, 2009

Today I got a few little things done and mainly drove the snot out of her for half an hour or so. The 5 speed shifter setup did the trick. Feels better than new now. And I found out what those little bushings I always have leftover from rebuilding my shifters are for... Duh bottom of the shift lever.

Turns out the dirty shifter assembly I got from the JY? It was brand new as soon as I cleaned it for a minute. It couldn't have been on that GTI for long. I am gonna have to go take a look at the rods and see how they look!

I am going to post up a seperate post inna minute here for a small DIY.

July 22, 2009

Older VW's frequently have an interesting problem where they will continue to run after the ignition switch is turned off. If the car is a gasser, then a very common reason for this is of all things a bad alternator. I have seen this on 5-6 cars easily where the fix is something not at all expected.

Try unplugging the blue exciter wire from the alternator. If this cures the problem, the fix is super easy. What happens is the diode array will start to break down inside the alternator. When this happens it will leak enough voltage back that it keeps enough power on the ignition switch. I see this MUCH more often on the cars I have MegaSquirted than CIS cars, but it applies equally. While replacing the alternator is the best solution, theres another one that also protects the car. Lets put a diode in the exciter wire!

The fix is simple. Find a good location to get into the harness going to the alternator. Its better to do this in the engine bay for space and longgevity reasons. While under the dash would look cleaner, its more prone to getting broken. Probably the best location is going to be close to the alternator.

1) Open the harness up and give yourself at least 6-8 inches off the alternator.

2) Cut the blue wire

3) Slide several pieces of heatshrink over the wires. I use three usually. Going from a shorter smaller one to a little bigger in size and length each time. The heatshrink will protect and the multiple layers will add strength and stiffness back to the wire.

4) Strip 1/2 to 3/4 of insulation off each wire

5) Find a 4001 diode or equivalent. A 4002 would work just as easily and so would many others. Radio Shack is a fine place for this. You want a standard diode rated at 12v and about an amp or so. A standard one will be black with a grey or silver band on one end.

6) The band will be on the side of the diode facing the alternator. Solder the ends. I usually twist the diode lead around the wire and then wrap the excess wire right up against the side of the diode. DO NOT just twist and think you will be okay. Solder.

7)After a good solid connections here, then I will go ahead and slide the first piece of heatshrink over and shrink it. Keeping it centered. Then the next, and finally the last piece. Again this is to protect and add strength back into the wire so it doesn't break off next to the diode.

8) Your done except to test it. Make sure the battery light comes on when you turn the key on and goes off when you start the car. And most importantly that your car now turns off when you turn the key off!

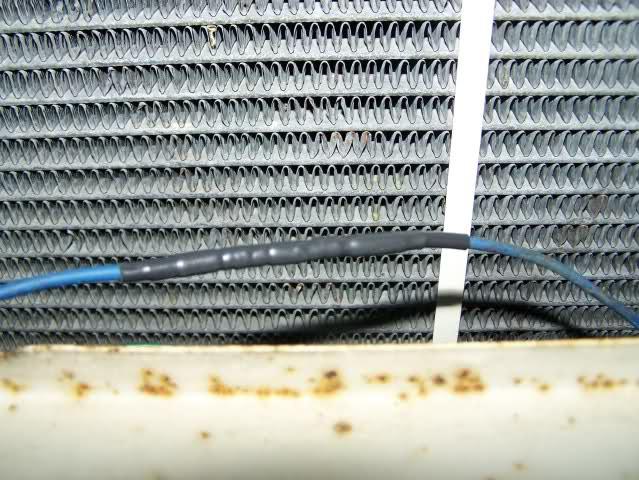

On my car I did this mainly to prevent this from ever happening. Its said that without this exciter wire hooked up the car actually will not charge. I guess it depends on the alternator. My 120amp VR6 one I ran for about a week without the exciter hooked up and it kept the battery 100% charged. I choose to place mine in the area in front of the radiator where I have my OE harness running as it will be deep in the wrapped section of that once I finish cleaning it all up.

Hopefully this helps somebody else out!

Ugh I need to straighten some fins on that radiator and it would look better with the center repainted nice and black, instead of slightly oxidized grey.

Oh well. Can't really see it with everything back together.

So I have gotten more than a couple IM's asking about how she drives. Like a freaking shifter cart! The alignment is dialed in almost 100%. If accelerate with my hands off the wheel she does pull slightly to the right. Goes mostly straight the rest of the time. I think I need about 1/8th degree more camber on the right. As of yet I haven't even set my gauge against the wheel though. I had it dialed in 110% on my cabby. When I pulled the coilovers off her I left the hubs and everything attached and unmolested. The lighter weight on this car is likely the culprit to my slight imperfections to the alignment.

Oh and the steering wheel is two teeth off....

Hard to say how much we got at the wheels. This car is a lot lighter than all my previous mk1's. I think the german shell alone is 200-300lbs lighter. Maybe I will go weigh her in tomorrow.... Anyways I have driven 200whp mk1's that were not this fast. So I am pretty confident we have at least 150whp on tap.

I am running @ 8-13psi. Max boost in my datalogs seems to be pretty inconsistent. Probably would help if I hooked up the wastegate hose and boost controller. But what would be the fun of starting off with minimum boost?