You must be logged in to rate content!

4 minute(s) of a 891 minute read

10-11-2008

It did. On my front subframe, there were an extra set of holes about an inch in front of the holes that the crossmember was originally bolted to, so I bolted the x-member to those holes and it worked out (because Carshop/S&P motor mount adapter plates I used moved the engine/tranny forward ~1 inch).

I'm back in town this weekend so hopefully I'll update some more pics and progress on the engine pull/investigation of oil pressure problem, and also on the seat install, steering wheel adjust, and pedal relocation (they're positioned awkwardly for my 6'2" height).

10-13-2008

Arg stupid engine comes back out...

Oh man I forgot how narsty the engine bay looks, like things usually go, putting the engine back in might be delayed to make this situation look a little more decent..

A shot of my modified oil pickup tube..

So I pulled the oil pickup, and I first thought this nick in the tube might've been the pressure-loss culprit...

..but then from the side it doesn't gouge into the tube, it's only on the inside surface, so back to square 1..

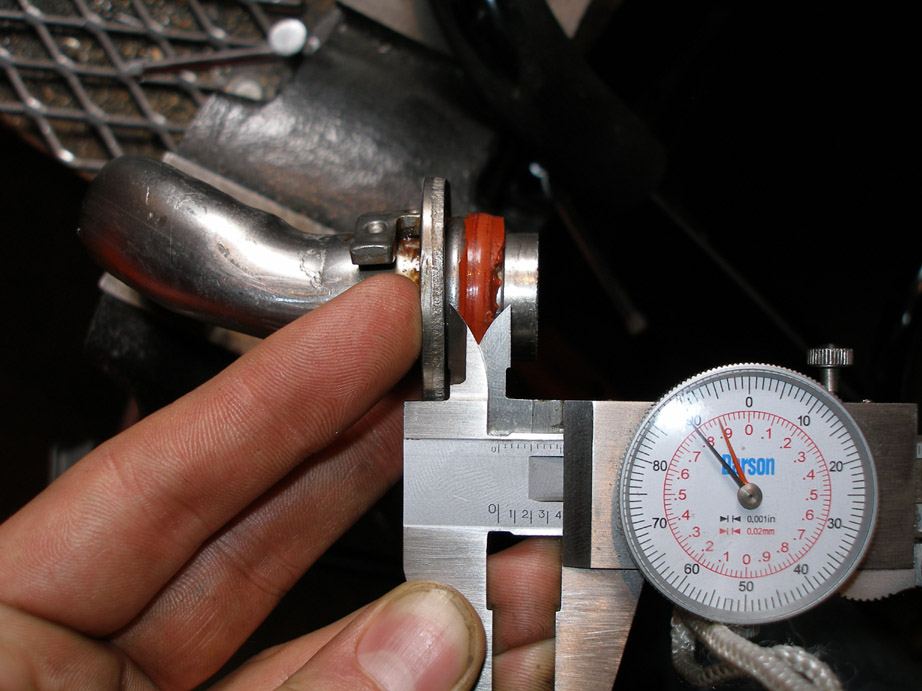

...So I measured the depth of the oil pump outer face to the mating surface that's supposed to compress the o-ring...

..and after multiple measurements I came up with a .390" depth..

and that same depth compared to the pickup shows that the o-ring doesn't even come close to the surface it's supposed to be compressed against!..

The first time I took the pickup off I fashioned a setup for the 2nd (unused) tapped hole, to double-bolt the pickup flange to the oil pump. I didn't like the idea that with a normal bolt/washer, it would only be pressuring against the washer at one point of the bolt head, but with this setup (off of a mountain bike brake pad retainer!) it allows full bolt head pressure to engage the off-angle washer..

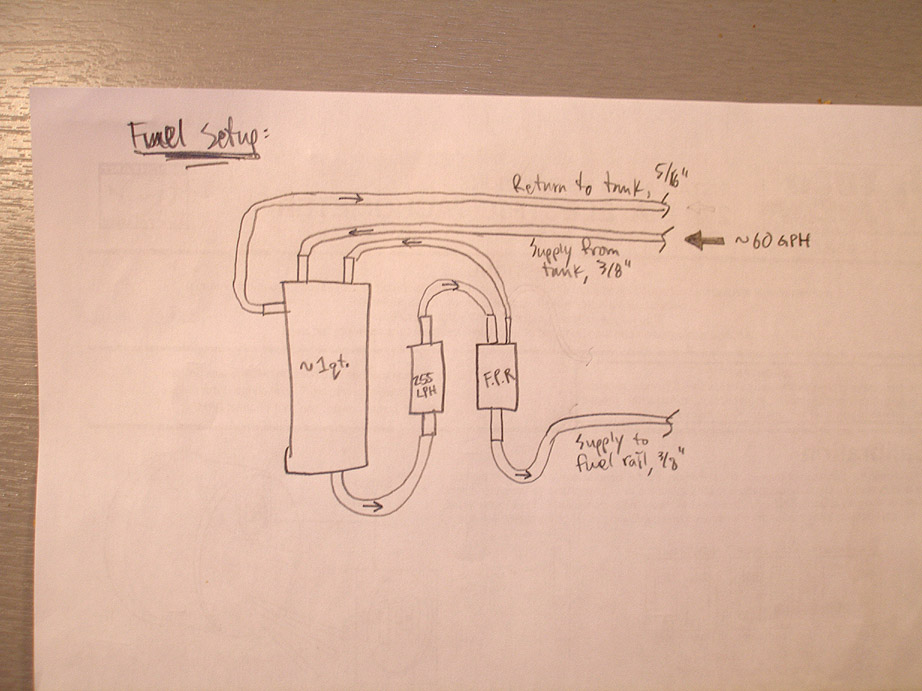

Another idea I've conjured up while bored in class is a way to guarantee fuel delivery.

Since I used the stock non-baffled, non-sumped tank, I didnt want to risk fuel starvation due to corners, acceleration, or hills (lots of them around here).

This is an idea which apparently euro/import autocrossers and racers have had for a while, so why not in an old american car?

A low-pressure carb pump will push fuel to the front of the car, into a skinny, tall canister from which the EFI pump will feed from the bottom. At 1G cornering, the gaslevel would be at 45*, and the only way there'll be no gas at the bottom of the canister is if the car is upside down or I hit a HUGE bump...

PS.. I've also done some calc's and with a 1qt canister, and 35lb injectors running WOT at 80% duty cycle (is this approx. correct??) the whole canister will drain in 28seconds if the pump at the back of the car fails.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM