You must be logged in to rate content!

7 minute(s) of a 88 minute read

2-26-2013

TA 0291110 Buildup

Compliments of slimfromnz @ www.v8buick.com

2-26-2013

Hi all,

I have deleted my previous build thread as things had changed and it got messy![]()

Ok,

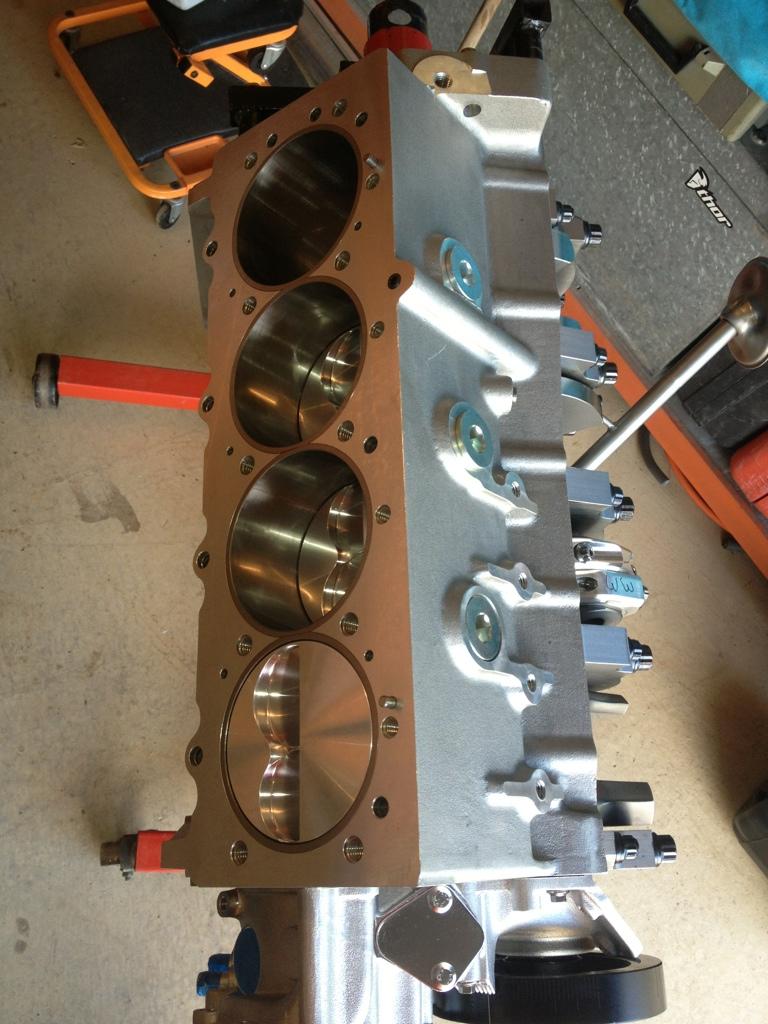

555cui TA455 block - 3" main , 54mm cam, etc

Crower 4.350" stroke crank

GRP 7" rods

JE 4.5" pistons 12.9:1 comp

Solid roller .625"-266', 110' LS cam

One off, tapered pushrods

Custom steel pan 3" deeper - factory position oil pump - custom TA pickup

TA front cover

Mezeire 55gph water pump

Stg 2 TE heads - 11/32" 2.260" valve set. PAC roller springs. 1.60:1 roller rockers (I am sure I have posted the flow sheets enough)

CFE custom sheetmetal tunnelram with polyethylene adaptor/heatsheild (4500 to 4150 style)

Twin 840cfm E85 Prosystem carburetors - enderle linkage kit

Custom ICE 7amp 2step ignition system with custom billet large cap distributor

2" custom 4 into 1 headers

RobMacc Starter with snout girdle

Internal balance SFI balancer

SFI flexplate

Mike estimates power in the 800-900hp range. The cam is somewhat small, but will give me some driveability on the street.

I have also ordered a stg 2 TH400 from Jim W complete with a 9.5" 3500rpm stall.

The best news is;

tomorrow I will be picking up the shortblock from the shipping yard to see it for the first time ![]()

I will post pics when I get it all unwrapped. The shortblock is complete ready for the heads, tunnelram etc then starting.

Cheers

2-27-2013

Before I release the pics, I just want to thank Mike, Sherri and the crew at TA Performance. It was definetly worth the wait.

Now just have to get the trans, fuel pump, bracketry sorted then I can start it![]()

![]()

Cheers

3-7-2013

Hi all,

You have seen pics of the motor mocked up, now its time for assembly.

I had to send the heads off to a machine shop to get the spring locators and retainers machined down to fit into the head pocket and fit inside the larger springs. He also supplied new billet locks and assembled the heads for me and charged me $220. This guy is actually a crew chief of one of the top running Top Fuel teams here, and was impressed with the motor and wants to dyno it when im ready.![]()

Ok, here is the head stud kit TA supplied me

Here are the heads back from the shop with new PAC racing springs installed, 225lbs seated, 600lbs open.

Shortblock ready for head studs

Head gasket by TA. Never seen em like this before.![]()

Studs in and gasket installed. I have to say these things drop right on with fitment to the locating dowels.

Head on. Same here, the heads drop on with ease with a slight fist tap to locate on the dowels.

Other side ready

Cheers

Heads all torqued down in stages as per TA. Its been a while since I have torqued heads down![]() 110ft/lbs geez it was hard work

110ft/lbs geez it was hard work![]()

Ready for these

All in.

Time for my super duper tapered pushrods. I wondered how I would oil these without getting my hands all over them. ![]() Cut the top of the bag open and poured oil into it

Cut the top of the bag open and poured oil into it

Pushrods installed

These have been soaking for 12 or so months.

New shafts as I struggled to stop the old ones going rusty. Yes I tried everything. We live right on the beach ![]()

One side installed

Covers on before I bag(plastic) it up for tomorrow

Cheers

Nice pics!

Posted by Diggymart on 5/12/20 @ 2:53:28 PM